Energy-saving, environment-friendly and continuous fabric washing, dyeing, baking and fixation method

An energy-saving and environmental-friendly fabric technology, which is applied in the continuous processing of textile materials, dyeing methods, and the processing of textile materials, can solve problems such as high energy consumption, high pollution, and environmental protection in the textile industry, and achieve reduced emissions and a high degree of intelligence , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

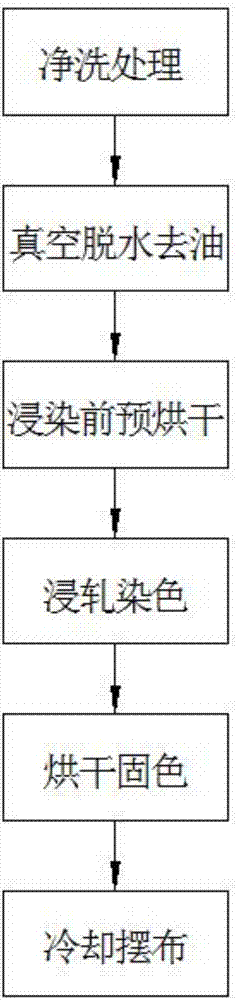

[0039] An energy-saving and environment-friendly continuous washing, dyeing and drying method for fabrics, comprising the following steps:

[0040] (1) The fabric enters the cleaning treatment device from the cloth feeding rack to remove the dirt and oil stains on the surface of the fabric. The cleaning solution used includes cleaning agent, wetting or penetrating agent, degreasing agent and water, and each group of cleaning solution Sub-mass percentages are as follows,

[0041] Detergent 0.001—5%;

[0042] Wetting agent or penetrating agent 0.001—5%;

[0043] Degreaser 0.001—5%;

[0044] The remaining components are water;

[0045] The temperature of the cleaning solution is set to 35-95 °C, and the speed of the pad car to transport the fabric during cleaning is set to 15-60 m / min;

[0046] In this step, the cleaning treatment device includes at least one cleaning unit, and each cleaning unit includes a cooking tank and a vibrating washing tank;

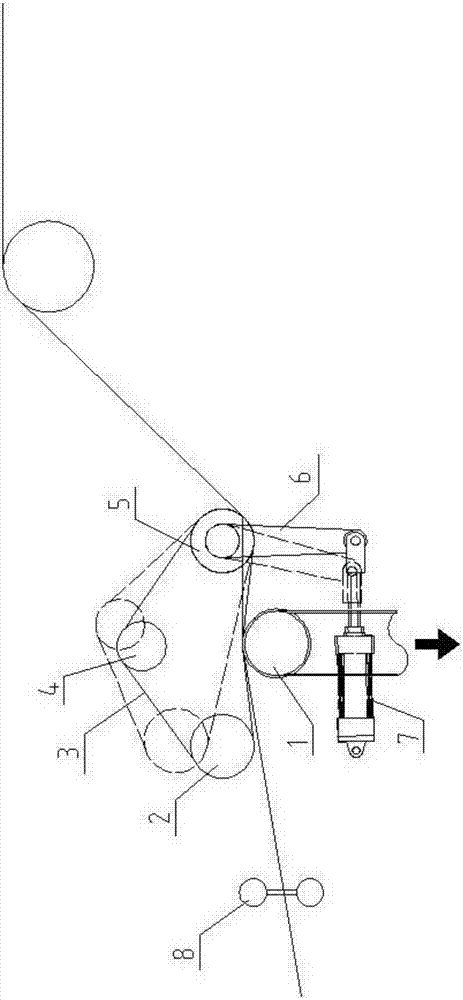

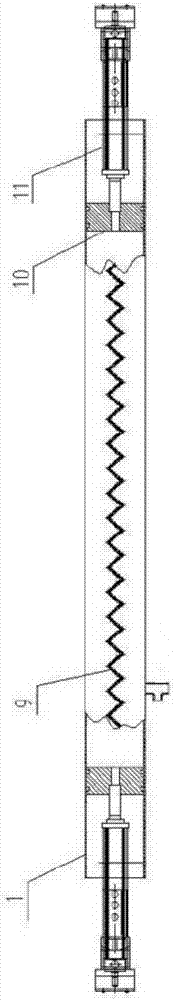

[0047] The oscillating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com