Finish material adhesive

A facing material and adhesive technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of not considering the comprehensive unit price, high price of tile adhesive, low price of cement mortar, etc. problems, to achieve significant technical significance and social significance, good technical effects, and enhanced function effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

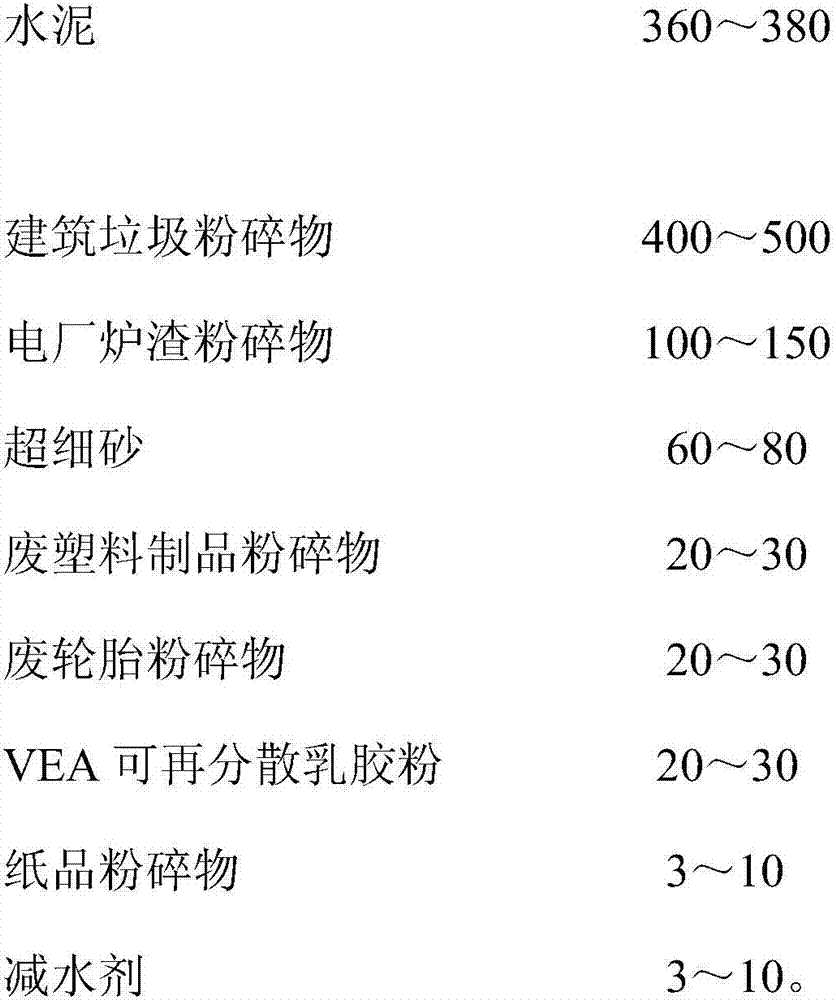

[0032] A binder for facing materials, which is characterized in that the weight ratio of raw materials used is as follows:

[0033]

[0034] Among them, the particle size of cement is 1000-2000 mesh, the particle size of crushed construction waste is 80-300 mesh, the particle size of power plant slag is 100-400 mesh, and the particle size of crushed waste plastic products and waste tires is 100-200 mesh. , The length of the paper crushed product is 1-10mm, and the particle size of the ultra-fine sand is 24μm. These raw materials can be obtained from relevant places.

[0035] The binder can be obtained after mixing the above-mentioned raw materials uniformly, and can be used after mixing with water at a mass ratio of 6:1 during use.

[0036] The specific production method is: respectively grinding construction waste, power plant slag, waste plastic products, waste tires, and waste paper products with a grinder to grind the ground construction waste, power plant slag crushed material, ...

Embodiment 2

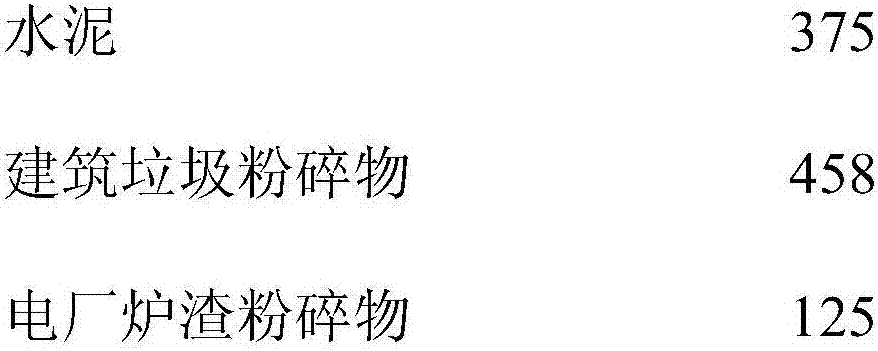

[0044] A binder for facing materials, which is characterized in that the weight ratio of raw materials used is as follows:

[0045]

[0046] Among them, the particle size of cement is 1000-2000 mesh, the particle size of crushed construction waste is 80-300 mesh, the particle size of power plant slag is 100-400 mesh, and the particle size of crushed waste plastic products and waste tires is 100-200 mesh. , The length of the paper crushed product is 1-10mm, and the particle size of the ultrafine sand is 26μm. These raw materials can be obtained from relevant places.

[0047] The binder can be obtained after mixing the above-mentioned raw materials uniformly, and can be used after mixing with water at a mass ratio of 7:1 during use.

[0048] The specific production method is: respectively grinding construction waste, power plant slag, waste plastic products, waste tires, and waste paper products with a grinder to grind the ground construction waste, power plant slag crushed material, a...

Embodiment 3

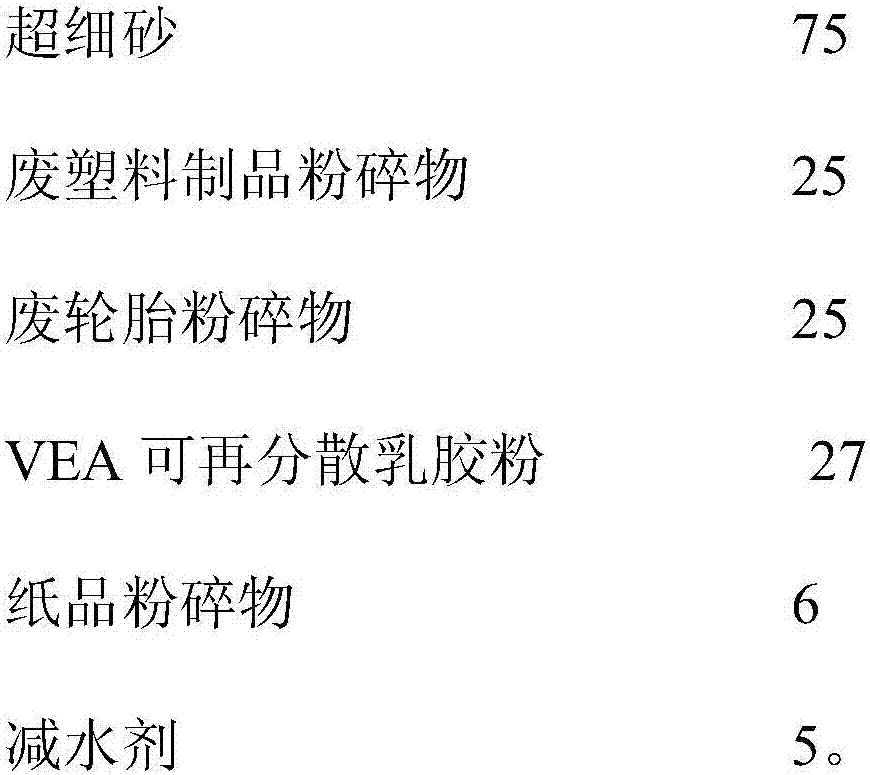

[0056] A binder for facing materials, which is characterized in that the weight ratio of raw materials used is as follows:

[0057]

[0058]

[0059] Among them, the particle size of cement is 1000-2000 mesh, the particle size of crushed construction waste is 80-300 mesh, the particle size of power plant slag is 100-400 mesh, and the particle size of crushed waste plastic products and waste tires is 100-200 mesh. , The length of the crushed paper is 1-10mm, and the particle size of the ultra-fine sand is 30μm. These raw materials can be obtained from relevant places.

[0060] The binder can be obtained after mixing the above-mentioned raw materials uniformly, and can be used after mixing with water at a mass ratio of 5:1 during use.

[0061] The specific production method is: respectively grinding construction waste, power plant slag, waste plastic products, waste tires, and waste paper products with a grinder to grind the ground construction waste, power plant slag crushed material,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com