Heat pipe radiator with variable-section hot end and multiple pulsation cold ends

A heat pipe radiator and variable cross-section technology, applied in the field of strengthening heat transfer, can solve problems such as affecting the heat dissipation effect, adding multiple solder joints, and lack of organic combination, so as to improve the heat and mass transfer performance, expand the cooling area of the cold end, The effect of increasing the pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

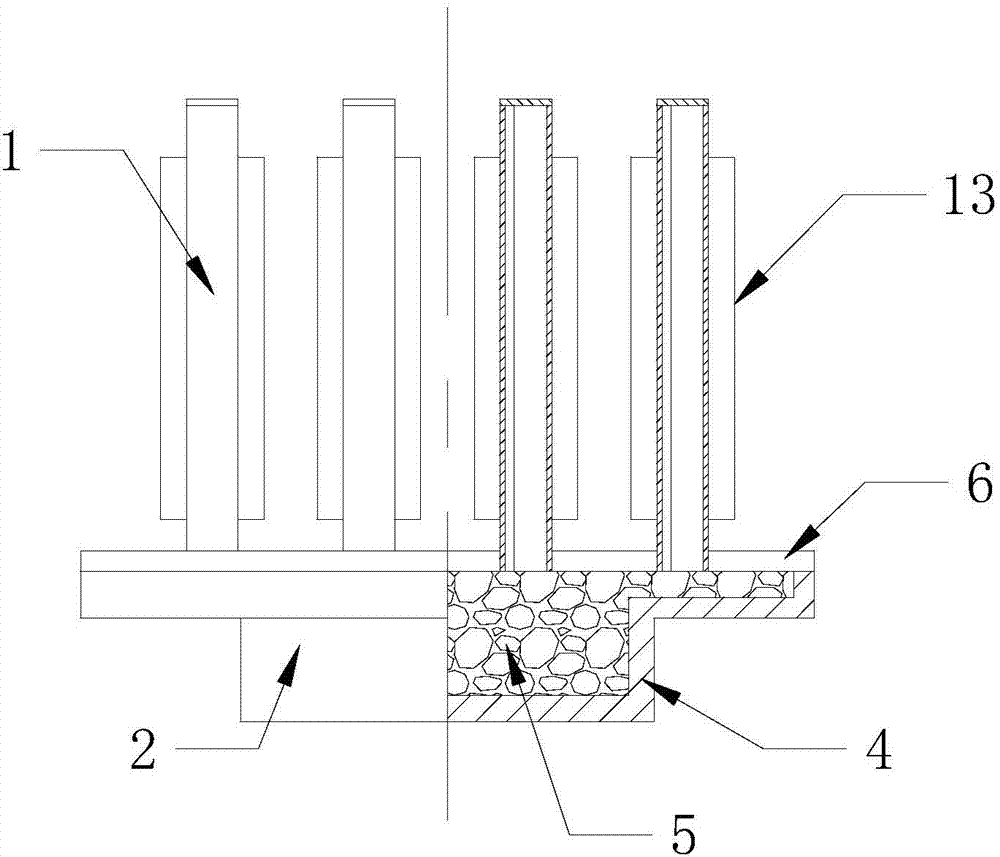

[0051] See attached figure 1 , 2 , 3, 4, 5, 6, a hot-end variable cross-section multi-pulsation cold-end heat pipe radiator, the hot-end variable cross-section multi-pulsation cold-end heat pipe radiator includes a pulsating cold end 1 and a hot end 2, in the The pulsating cold end 1 is provided with a plurality of heat dissipation plates with pulsating passages 3; the hot end is a hollow cavity 4, which is filled with working fluid and capillary liquid-absorbing core 5; the hot end is hollow The upper cover plate 6 of the cavity 4 is provided with a plurality of cold end interfaces 7, and each cold end interface 7 is equipped with a pulsating cold end 1, so that the pulsating channel 3 of the pulsating cold end 1 and the hollow cavity of the hot end 2 body 4 connected;

[0052] The area of the upper cover plate 6 of the hot-end hollow cavity 4 is 2.5 times the area of the lower cover plate 8, and two right-angle pressure-bearing hoops with large compressive capacity are...

Embodiment 2

[0065] See attached Figure 7 , 8 , a hot-end variable cross-section multi-pulsation cold-end heat pipe radiator, the hot-end variable-section multi-pulsation cold-end heat pipe radiator includes a pulsating cold end 1 and a hot end 2, and multiple pulsating cold ends 1 are provided The heat dissipation plate body of the pulsating channel 3; the hot end is a hollow cavity 4, which is filled with working fluid and capillary liquid-absorbing core 5; on the upper cover plate 6 of the hollow cavity 4 of the hot end A plurality of cold end interfaces 7 are provided, and each cold end interface 7 is equipped with a pulsating cold end 1, so that the pulsating channel 3 of the pulsating cold end 1 communicates with the hollow cavity 4 of the hot end 2;

[0066] The area of the upper cover plate 6 of the hot-end hollow cavity 4 is 2.0 times the area of the lower cover plate 8, and two right-angle pressure-bearing hoops with large compressive capacity are added by adopting the step...

Embodiment 3

[0079] See attached Figure 9 , 10 , 11. A hot-end variable cross-section multi-pulsation cold-end heat pipe radiator, the hot-end variable-section multi-pulse cold-end heat pipe radiator includes a pulsating cold end 1 and a hot end 2, and the pulsating cold end 1 is provided with The heat dissipation plate body of a plurality of pulsating channels 3; the hot end is a hollow cavity 4, which is filled with working fluid and capillary liquid-absorbing core 5; the upper cover plate of the hollow cavity 4 at the hot end 6 is provided with a plurality of cold end interfaces 7, and each cold end interface 7 is equipped with a pulsating cold end 1, so that the pulsating channel 3 of the pulsating cold end 1 communicates with the hollow cavity 4 of the hot end 2;

[0080] The area of the upper cover plate 6 of the hot-end hollow cavity 4 is 3.5 times the area of the lower cover plate 8, and two right-angle pressure-bearing sides with large compressive capacity are added by adopt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equivalent diameter | aaaaa | aaaaa |

| Equivalent diameter | aaaaa | aaaaa |

| Equivalent diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com