Hard-sealing spherical valve suitable for water-coal-slurry working condition

A hard sealing, coal-water slurry technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of difficult processing, affecting the overall sealing performance of the valve, and inability to process, and achieves high sealing shear force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

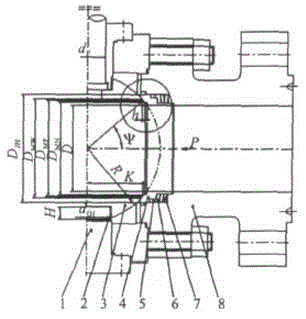

[0031] A hard-sealed ball valve suitable for the working condition of coal-water slurry, which consists of: an end cover, the end cover is connected with a disc spring, the disc spring is connected with a pressure ring, and the pressure ring is connected with a seal Ring connection, the sealing ring is connected with the valve seat, the valve seat is connected with the sphere, the sphere is covered with a shaft sleeve, and the shaft sleeve is covered with a pivot;

[0032] Due to the use of metal materials as the sealing surface, the required sealing specific pressure is much higher than that of the soft seal. The combined valve seat structure of "spring + valve seat" is adopted, and the initial pre-tightened sealing specific pressure is provided by the high-load disc spring. Considering Influenced by the linear expansion of metal materials at high temperatures, the combined design of disc springs in series is adopted, which not only satisfies the initial preload provided by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com