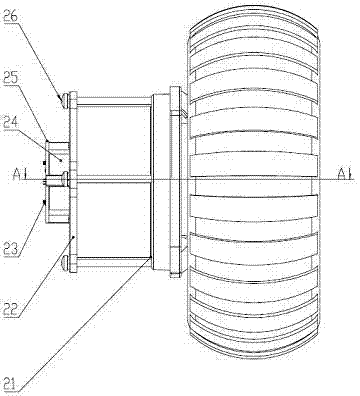

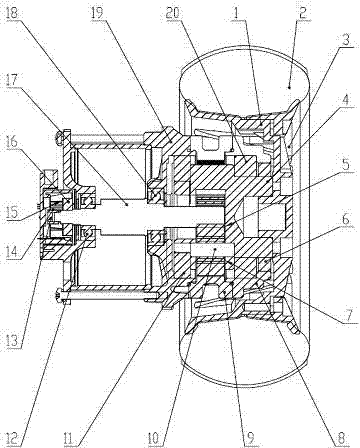

Driving mechanism of retarding motor

A driving mechanism and deceleration motor technology, applied in the direction of motors, motor vehicles, electric vehicles, etc., can solve the problems of large lateral size, large vehicle volume, heavy weight, etc., and achieve reduced axial size, simple and compact structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Such as figure 1 and figure 2 As shown, the geared motor drive mechanism of the present invention includes a brushless motor, a planetary reducer and a hub mechanism assembled into one; wherein the brushless motor includes a motor shaft (17), and two bearings installed at both ends of the motor shaft (17) (12) and (18), a position sensing magnet (16) fixed at the non-output end of the motor shaft (17), an encoder magnet (13) installed at the non-output end of the motor shaft (17), and a Install the aluminum tube (14) of the encoder magnet (13), a spacer (15), a motor end cover (19), a motor rear cover (22), and 3 pieces are evenly distributed on the Hall fixing frame (24) Hall sensor (23), an encoder Hall plate (25) installed at the end of the motor, a Hall fixing frame (24) and 4 pan head screws (26) used to connect the motor and reducer.

[0022] The planetary reducer includes 3 bearings (6), (11) and (20) installed at both ends of the output shaft (4), one output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com