Treatment device and treatment method for high-salt refractory wastewater

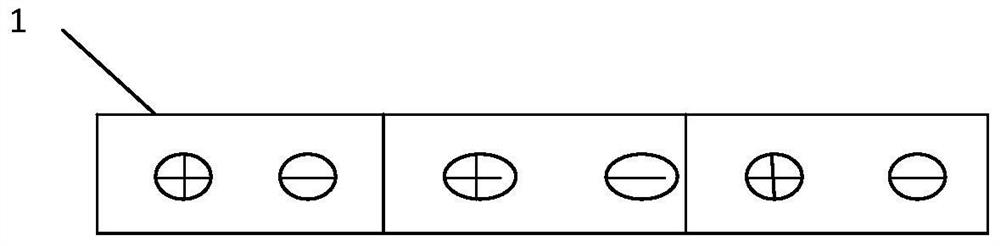

A treatment device, a refractory technology, applied in water/sewage treatment, special compound water treatment, illumination water/sewage treatment, etc., can solve the problem of inability to use high voltage, achieve non-selective degradation, improve catalytic degradation efficiency, Strong oxidizing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

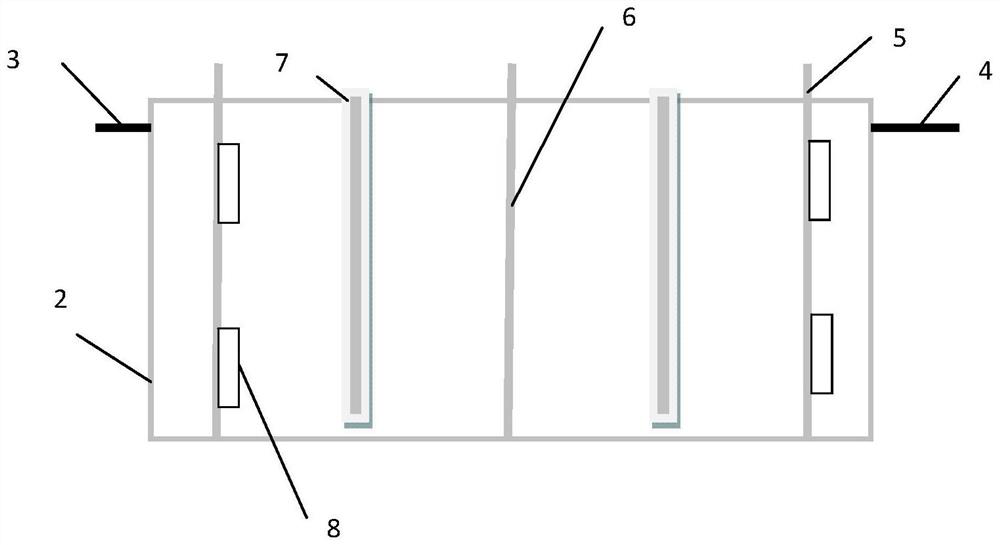

Embodiment 1

[0065] Treatment of resin regeneration wastewater in a chemical water production workshop of a thermal power plant: the catalytic anode uses titanium-based IrO 2 Coated electrode, the cathode is made of stainless steel electrode, the distance between the plates is 5 cm, and the current density is 2.5mA / cm 2 , the ultraviolet lamp tube 7 is perpendicular to the horizontal plane, the distance between two adjacent ultraviolet lamps is 50 cm, the wavelength of ultraviolet light emitted by the ultraviolet lamp is 100 nm, the parallel and vertical distances of the ultrasonic transducers on each surface of the stainless steel cathode are equal, which is 20 cm, and the ultrasonic frequency is adjusted The range is 200KHZ; the ultrasonic sound intensity adjustment range is 10W / cm 2 ; The residence time of waste water in the oxidation reaction tank is 15 minutes.

[0066] The influent COD is 80mg / L, the conductivity is 25000μs / cm; the effluent COD is 28mg / L, the conductivity is 24800μs...

Embodiment 2

[0068] The treatment device and method provided by the present invention are used to treat the production wastewater of an aniline workshop in a chemical plant: wherein the catalytic anode adopts titanium-based PbO 2 Coated electrode, the cathode is made of stainless steel electrode, the distance between the plates is 5 cm, and the current density is 50mA / cm 2 , the ultraviolet lamp tube 7 is perpendicular to the horizontal plane, the distance between two adjacent ultraviolet lamps is 20 cm, the wavelength of ultraviolet light emitted by the ultraviolet lamp is 50 nm, the parallel and vertical distances of the ultrasonic transducers on each surface of the stainless steel cathode are equal, which is 10 cm, and the ultrasonic frequency is adjusted The range is 600KHZ; the ultrasonic sound intensity adjustment range is 100W / cm 2 ; The residence time of waste water in the oxidation reaction tank is 120 minutes.

[0069] The influent COD is 4800mg / L, the conductivity is 65000μs / cm...

Embodiment 3

[0071] The biochemical effluent of certain acrylic fiber wastewater is treated by using the treatment device and method provided by the present invention: wherein the catalytic anode adopts titanium-based PbO 2 Coated electrode, the cathode is made of stainless steel electrode, the distance between the plates is 10 cm, and the current density is 25mA / cm 2 , the ultraviolet lamp tube 7 is horizontal to the horizontal plane, the distance between two adjacent ultraviolet lamps is 25 cm, the wavelength of ultraviolet light emitted by the ultraviolet lamp is 200 nm, the parallel and vertical distances of the ultrasonic transducers on each surface of the stainless steel cathode are equal, which is 15 cm, and the ultrasonic frequency is adjusted The range is 800KHZ; the ultrasonic sound intensity adjustment range is 50W / cm 2 ; The residence time of waste water in the oxidation reaction tank is 60 minutes.

[0072]The influent COD is 320mg / L, the conductivity is 12800μs / cm; the efflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com