A kind of diesel engine oil with high supercharging and long service life and preparation method thereof

A diesel engine oil, long-life technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor high-temperature performance of viscosity index improvers, unfavorable detergency and oxidation resistance of oil products, and pressure reduction of diesel vehicles, etc. Achieve excellent high-temperature detergency, inhibit carbon deposits and varnish formation, and prolong oil change intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

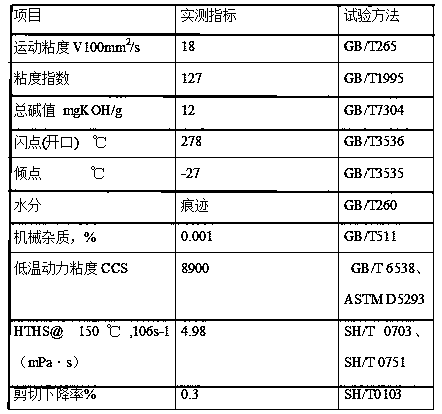

[0019] Embodiment 1: A kind of diesel engine oil of high pressurization and long life, prepare paraffin base type II 500N 928kg, viscosity is 100mm under 100 ℃ 2 / s Polyalphaolefin (150) 48kg, Polyester PriEco (4035) 24kg, Superbasic Calcium Sulfonate 20kg, Polyisobutylene Polysuccinimide 80kg, Sulfurized Calcium Alkylphenate 15kg, Phosphobisoctyl Base 15kg of non-toxic zinc salt, 0.01kg of oil-soluble graphene, 3kg of amine-type high-temperature antioxidant, 1kg of polymethacrylate depressant, and 0.01kg of composite antifoaming agent;

[0020] Production method: put 500N, polyalphaolefin (150), polyester PriEco (4035) into the reaction kettle, heat up to 60°C-70°C, stir for 10 minutes, then put in superbasic calcium sulfonate, sulfurized alkylphenol in turn Calcium, polyisobutylene polysuccinimide, amine-type high-temperature antioxidant, polymethacrylate, thiophosphobisoctyl basic zinc salt, composite antifoaming agent, oil-soluble graphene, constant temperature 60°C-70°C ...

Embodiment 2

[0023] Embodiment 2: A kind of diesel engine oil with high supercharging and long life, prepare paraffin base III type 650N 915kg, the viscosity is 300mm under 100 ℃ 2 / s polyalphaolefin (200) 80kg, trimethylolpropane oleate 5kg, superbasic calcium sulfonate 22kg, polyisobutylene polysuccinimide 85kg, sulfurized alkylphenate calcium 13kg, thiophosphobioctine 15kg basic zinc salt, 0.01kg oil-soluble graphene, 4kg amine high-temperature antioxidant, 1kg polymethacrylate pour point depressant, 0.013kg composite antifoaming agent;

[0024] Production method: put 650N, polyalphaolefin (200), trimethylolpropane oleate into the reaction kettle, raise the temperature to 60°C-70°C and stir for 10 minutes, then put in superbasic calcium sulfonate, sulfurized alkyl Calcium phenate, polyisobutylene polysuccinimide, amine-type high-temperature antioxidant, polymethacrylate, bis-octyl basic zinc salt of sulfur phosphorus, composite antifoaming agent, oil-soluble graphene, constant temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com