A kind of preparation method of the polyalpha-olefin synthetic oil of high viscosity index

An olefin synthetic oil, high-viscosity technology, used in chemical instruments and methods, petroleum industry, lubricating compositions, etc., can solve problems such as product performance description, and achieve the effects of improving utilization rate, reducing cost, and simple and convenient process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

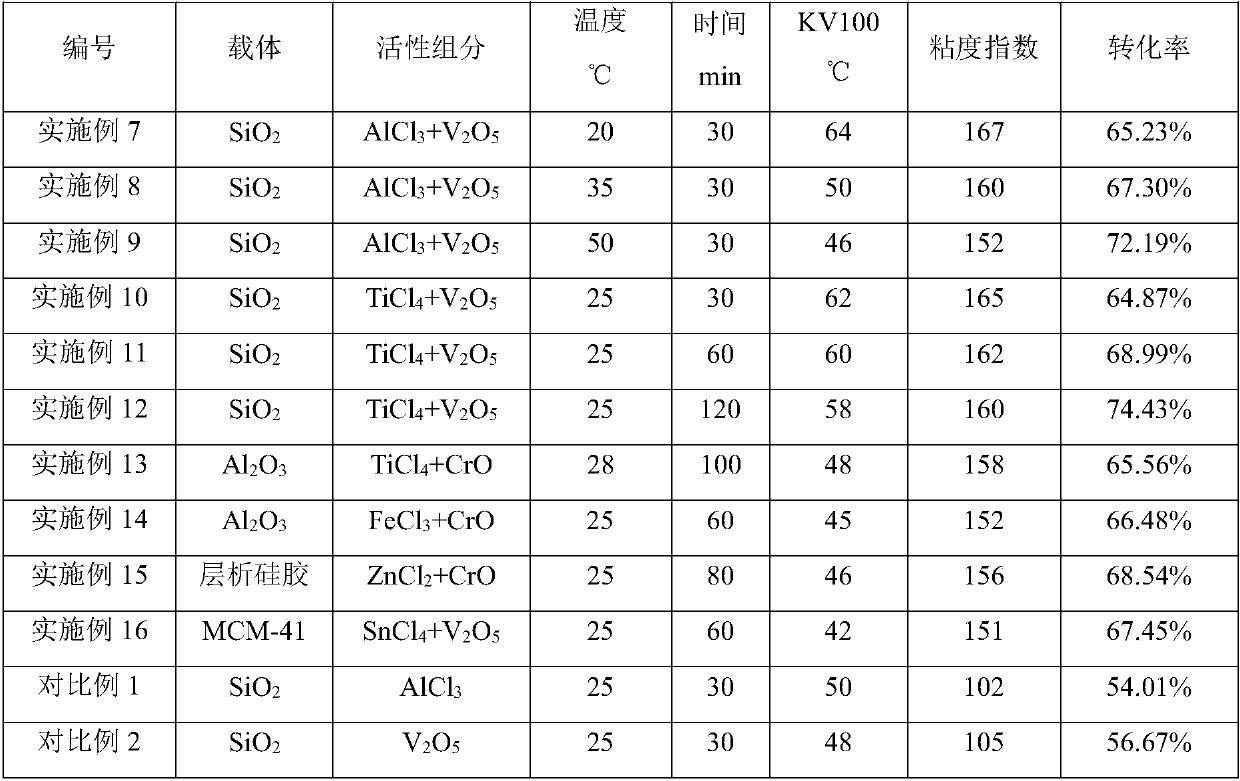

Examples

Embodiment 1

[0029] The preparation of embodiment 1 oligomerization catalyst

[0030] 8g silica (pore volume is 0.50cm 3 / g, the average pore diameter is 2.0nm, and the specific surface area is 158m 2 / g) impregnated in vanadium nitrate aqueous solution (vanadium loading capacity is 0.20wt%), continuously stirred and dipped in 25°C water bath for 30min, filtered, and vacuum dried at 100°C for 6h; place the silica carrier impregnated with vanadium nitrate in muffle For roasting in the furnace, the temperature was first raised to 120°C and kept at a constant temperature for 2 hours, then the temperature was raised to 350°C and kept at a constant temperature for 1 hour, then the temperature was further raised to 450°C and kept at a constant temperature for 6 hours, and finally the temperature was naturally lowered and cooled under nitrogen. The obtained sample was immersed again in a toluene solution of aluminum trichloride (the Al loading was 12.00 wt%), continuously stirred and impregnated ...

Embodiment 2

[0031] Embodiment 2 Preparation of oligomerization catalyst

[0032] 8g silica (pore volume is 0.58cm 3 / g, the average pore diameter is 12.5nm, and the specific surface area is 100m 2 / g) impregnated in an aqueous solution of vanadyl oxalate (the loading capacity of vanadium is 0.58wt%), impregnated with continuous stirring in a water bath at 45°C for 50min, filtered, and dried in vacuum at 100°C for 6h; the silica carrier impregnated with vanadyl oxalate was placed on Roasting in the muffle furnace, the temperature was first raised to 120°C, kept at a constant temperature for 2 hours, then raised to 350°C, held at a constant temperature for 1 hour, continued to be heated to 450°C, held at a constant temperature for 6 hours, and finally cooled naturally under nitrogen. The obtained sample was again immersed in an isopropanol solution of titanium tetrachloride (Ti loading was 10.68wt%), impregnated with continuous stirring at room temperature for 2 hours, and vacuum-dried at ...

Embodiment 3

[0033] The preparation of embodiment 3 oligomerization catalyst

[0034] 10g of aluminum oxide (γ-alumina, the pore volume is 1.34cm 3 / g, the average pore diameter is 20nm, and the specific surface area is 220m 2 / g) impregnated in chromium acetate aqueous solution (the chromium loading capacity is 12.00wt%), continuously stirred and impregnated in a water bath at 25°C for 60min, filtered, and vacuum-dried at 100°C for 6h; Roasting in the Fu furnace, first raise the temperature to 120°C, keep the temperature for 2h, then raise the temperature to 350°C, keep the temperature for 1h, continue to raise the temperature to 550°C, keep the temperature for 6h, and finally cool down naturally under nitrogen to 200-300°C, and introduce reducing Gas H 2 , for 1-3h, the contained chromium oxide is reduced to low-priced chromium oxide. The obtained sample was immersed again in an isopropanol solution of titanium tetrachloride (0.10wt% Ti loading), impregnated with continuous stirring a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com