Preparation method of organosilicone ternary block copolymer

A ternary block and silicone technology, applied in the direction of improved hand feeling fiber, liquid repellent fiber, etc., can solve the problems of poor hydrophilicity, easy demulsification, sticking to rolls, etc., and achieve the solution of easy demulsification, Good chemical stability, improve the effect of taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

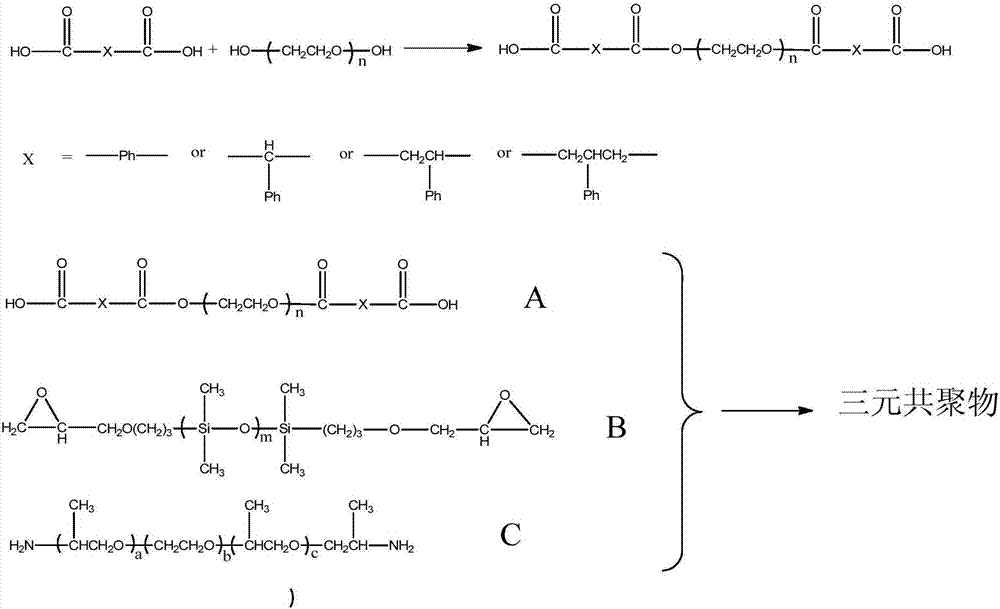

Method used

Image

Examples

Embodiment 1

[0029] Add 6.6 grams of terephthalic acid (0.04mol) and 16 grams of polyethylene glycol 800 (0.02mol) into the reactor, and react at 150°C for 12 hours under the protection of nitrogen to obtain polyethylene glycol terephthalate; Add 100 grams of amino polyether (molecular weight 1000, 0.1mol) and 360 grams of epoxy silicone oil (molecular weight 3000, 0.12mol) to the above product, use isopropanol as a medium, and add an appropriate amount of tetrabutylammonium bromide, heat React at 85°C for 24 hours, and the organosilicon ternary block copolymer is obtained after the reaction is completed.

Embodiment 2

[0031] Add 15.5 grams of phenylsuccinic acid (0.08mol) and 16 grams of polyethylene glycol 400 (0.04mol) into the reactor, and react at 150°C for 12 hours under the protection of nitrogen to obtain polyethylene glycol phenylsuccinate; Add 200 grams of amino polyether (molecular weight 2000, 0.1mol) and 560 grams of epoxy silicone oil (molecular weight 4000, 0.14mol) to the above product, use isopropanol as a medium, and add an appropriate amount of tetraethylammonium bromide, heat React at 85°C for 30 hours, and the organosilicon ternary block copolymer is obtained after the reaction is completed.

Embodiment 3

[0033] Add 33.8 grams of isophthalic acid (0.12 mol) and 60 grams of polyethylene glycol 1000 (0.06 mol) into the reactor, and react at 150°C for 12 hours under the protection of nitrogen to obtain polyethylene glycol isophthalic acid Ester; Add 300 grams of amino polyether (molecular weight 3000, 0.1mol), 800 grams of epoxy silicone oil (molecular weight 5000, 0.16mol) to the above product, take isopropanol as the medium, and add an appropriate amount of tetraethylammonium hydroxide , heated to 85°C and reacted for 36 hours, and the organosilicon ternary block copolymer was obtained after the reaction was completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com