A method for dry transfer of graphene on a metal substrate

A metal substrate, dry transfer technology, applied in the direction of graphene, nano-carbon, etc., can solve problems such as unintentional doping, achieve the effect of reducing influence, high repeatability, and avoiding unintentional doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

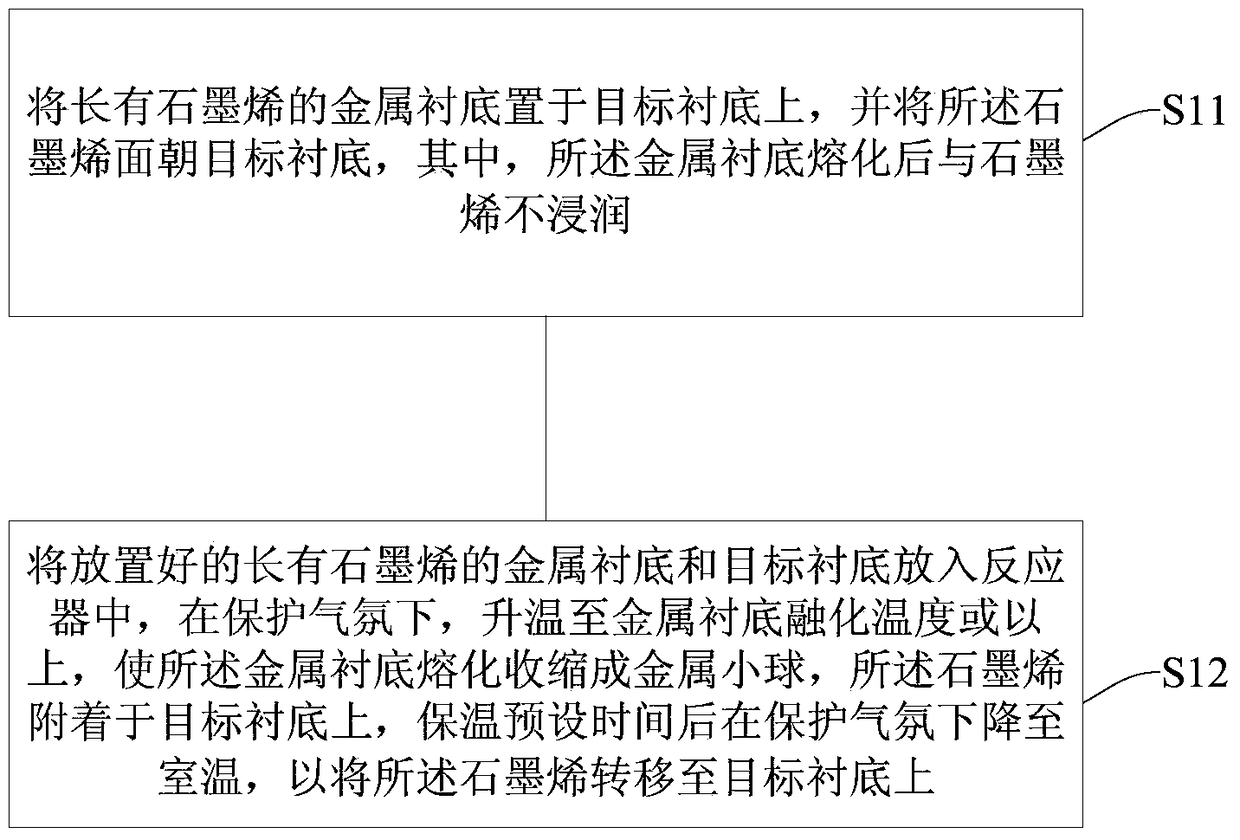

[0033] Such as Figure 1 to Figure 8 As shown, the present embodiment provides a method for dry transfer of graphene on a metal substrate, comprising steps:

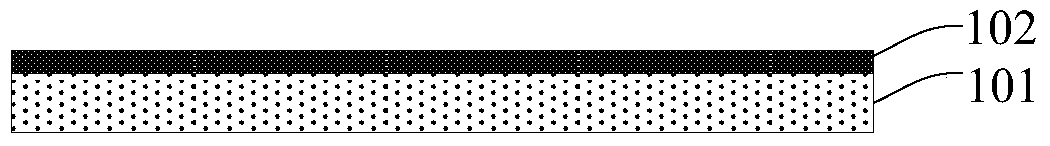

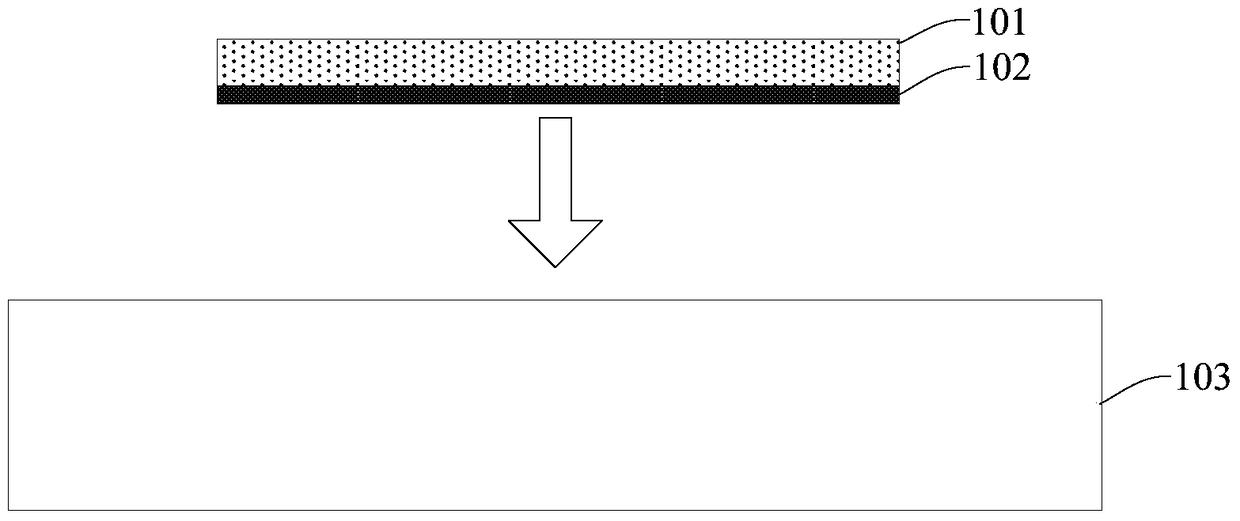

[0034] Such as Figure 1 ~ Figure 4 As shown, at first step 1) S11 is carried out, the metal substrate 101 with graphene 102 is placed on the target substrate 103, and the graphene 102 faces the target substrate 103, wherein the metal substrate 101 does not infiltrate with graphene 102 after melting.

[0035] As an example, the graphene 102 includes one or a combination of graphene separated crystal domains and graphene continuous films. In this embodiment, the graphene 102 is a graphene continuous film.

[0036] As an example, the material of the metal substrate 101 includes one or an alloy of two or more of copper, nickel, cobalt and ruthenium. In this embodiment, the material of the metal substrate 101 is copper.

[0037] As an example, the melting point of the target substrate 103 is higher than that of the corr...

Embodiment 2

[0052] Such as Figure 1 to Figure 6 as well as Figure 9 As shown, the present embodiment provides a method for dry transfer of graphene on a metal substrate, and its basic steps are as in embodiment 1, wherein, in the present embodiment, transferring graphene on copper to a sapphire substrate by a dry method is Examples are further explained. Specifically, the following steps are included:

[0053] In step 1), the copper substrate with graphene is placed on the sapphire substrate, and the side with graphene is close to the target substrate.

[0054] In step 2), put the put metal substrate and the target substrate together into a common CVD growth system, evacuate to 1Pa, and then pass argon gas to normal pressure.

[0055] Step 3), under the protection of 1000sccm argon, 20sccm hydrogen, 0.1sccm methane mixed gas, the temperature is raised to 1200 degrees centigrade, and maintained for 30 minutes, and the heating rate is selected as 5 degrees centigrade / minute.

[0056] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com