Friction lubrication performance evaluation method for casting powder of continuous casting mold

A continuous casting crystallizer and lubrication performance technology, applied in the direction of instruments, measuring devices, mechanical devices, etc., to achieve the effect of optimizing performance and improving the quality of casting slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

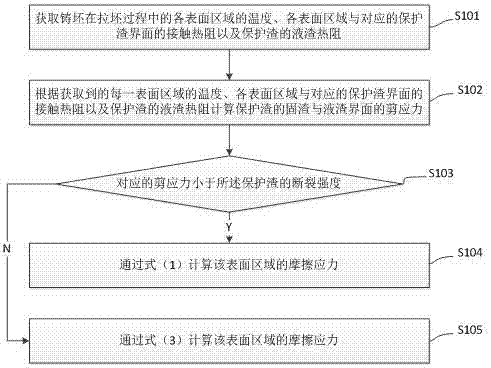

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0074] The tensile fracture strength of continuous casting mold flux was tested in the following manner.

[0075] 1) First heat the mold slag for the continuous casting mold at 600-700°C for 30 minutes to remove the carbon in it, then cool it down to room temperature naturally to obtain the decarbonized mold slag; crush the decarbonized mold slag and pass through a 40-mesh sieve, Take the undersize and dry it in a vacuum oven at 60°C to constant weight to obtain the decarbonized mold slag powder.

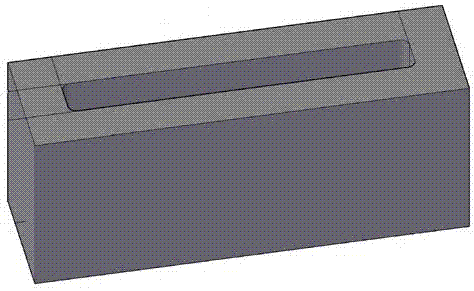

[0076] 2) Put the carbon-removing mold slag powder into the cavity of the graphite tank (the cavity size is 80mm×10mm×30mm), then place it at 1200°C for 20 minutes, and take it out after air cooling to room temperature to obtain a cuboid mold slag block.

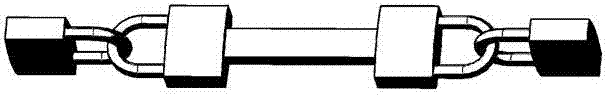

[0077] 3) The two ends of the mold slag block are respectively bonded to the plane of one carabiner with AB glue, and the lock ring is connected with the lock ring of the other carabiner. Then fix the two outer carabiners on the...

specific Embodiment 2

[0080] The compressive fracture strength of the continuous casting mold powder was tested in the following way.

[0081] 1) First heat the mold slag for the continuous casting mold at 600-700°C for 30 minutes to remove the carbon in it, then cool it down to room temperature naturally to obtain the decarbonized mold slag; crush the decarbonized mold slag and pass through a 40-mesh sieve, Take the undersize and dry it in a vacuum oven at 60°C to constant weight to obtain the decarbonized mold slag powder.

[0082] 2) Put the carbon-removing mold slag powder into the cavity of the graphite tank (the cavity size is 80mm×10mm×30mm), then place it at 1200°C for 20 minutes, and take it out after air cooling to room temperature to obtain a cuboid mold slag block.

[0083]3) The two ends of the mold slag block are respectively bonded to the plane of one carabiner with AB glue, and the lock ring is connected with the lock ring of the other carabiner. Then fix the two outer carabiners ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com