A Method for Obtaining the Process Parameter Domain of Anti-fatigue Grinding of Ultra-High Strength Steel Components

A technology of ultra-high-strength steel and process parameters, applied in the direction of testing wear resistance, etc., can solve the problems of poor surface integrity and low fatigue performance, and achieve the effect of accurate relationship model and reliable design and analysis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0048] The invention discloses a method for obtaining an anti-fatigue grinding process parameter domain of an ultra-high-strength steel component, which includes the following steps:

[0049] Step 1. According to the aviation manufacturing engineering manual, experience or literature, establish the grinding process parameter domain C of the ultra-high strength steel Aermet100 component 1 , where the ultra-high-strength steel Aermet100 grinding process parameter domain C 1 including wheel speed v s (unit is m / s), member velocity v w (unit is m / min), longitudinal feed a f (unit: mm / r), radial feed a p (in mm), that is, C 1 [v s ,v w ,a f ,a p ], its specific parameters refer to Table 1:

[0050]

[0051] Table 1

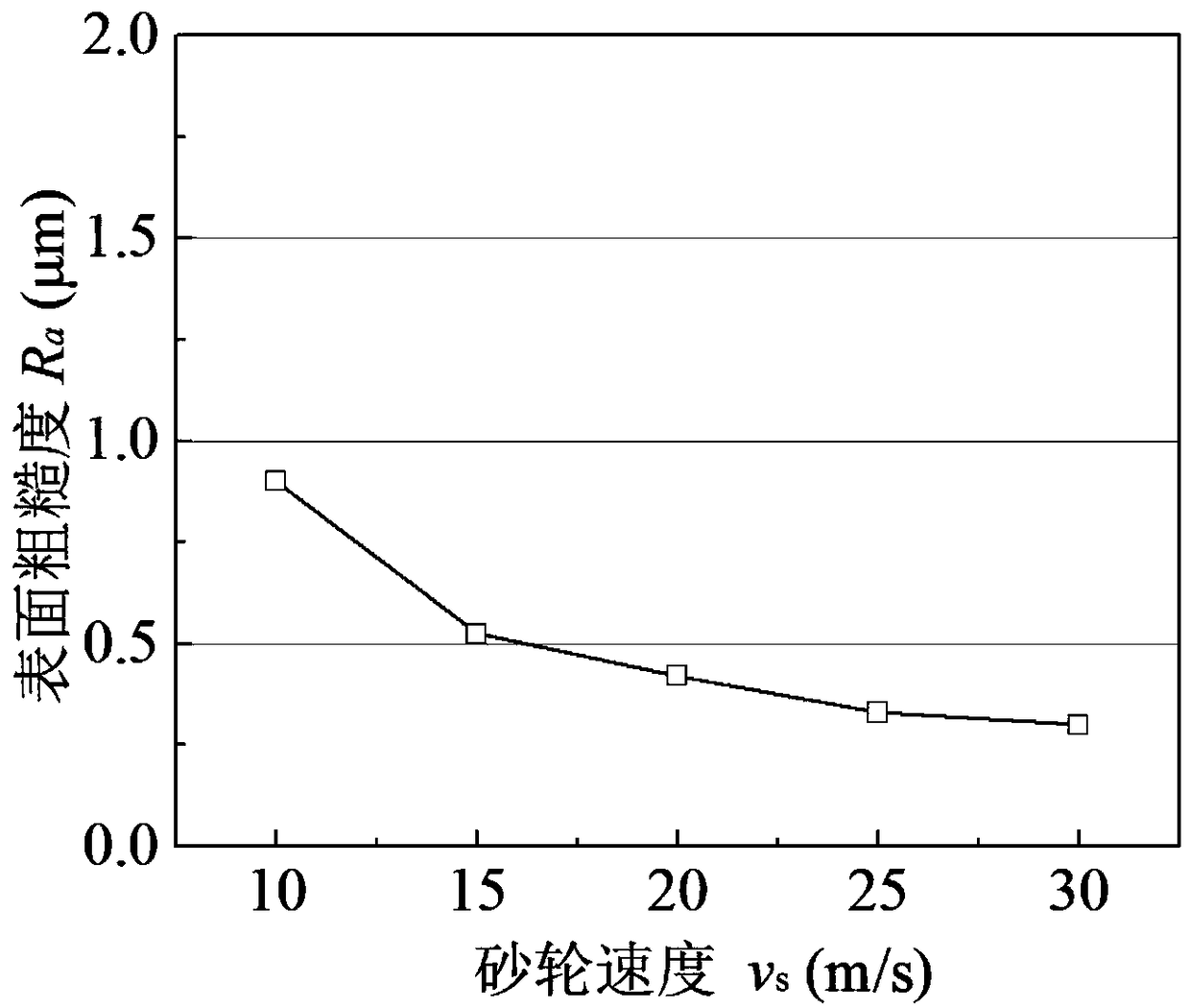

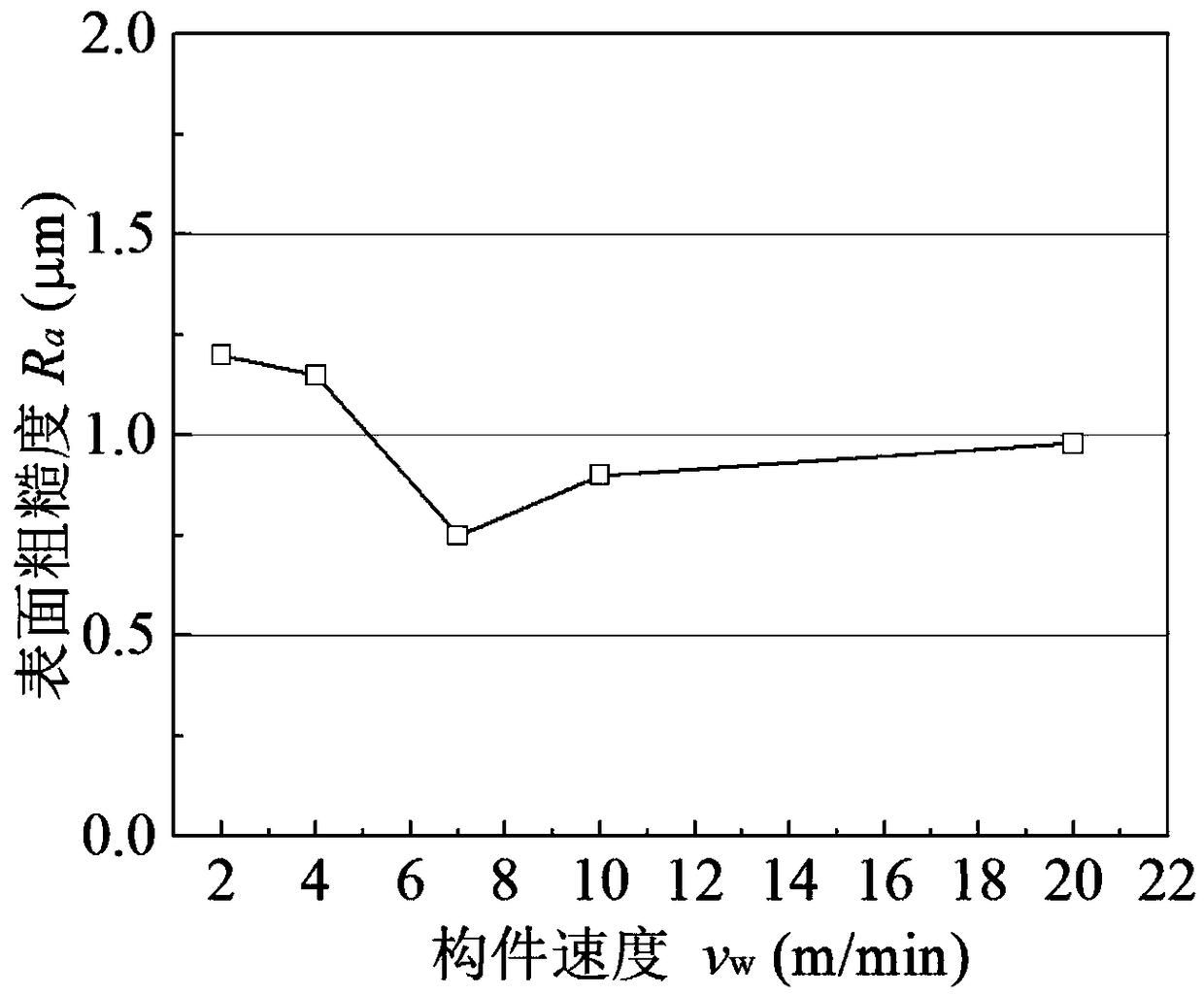

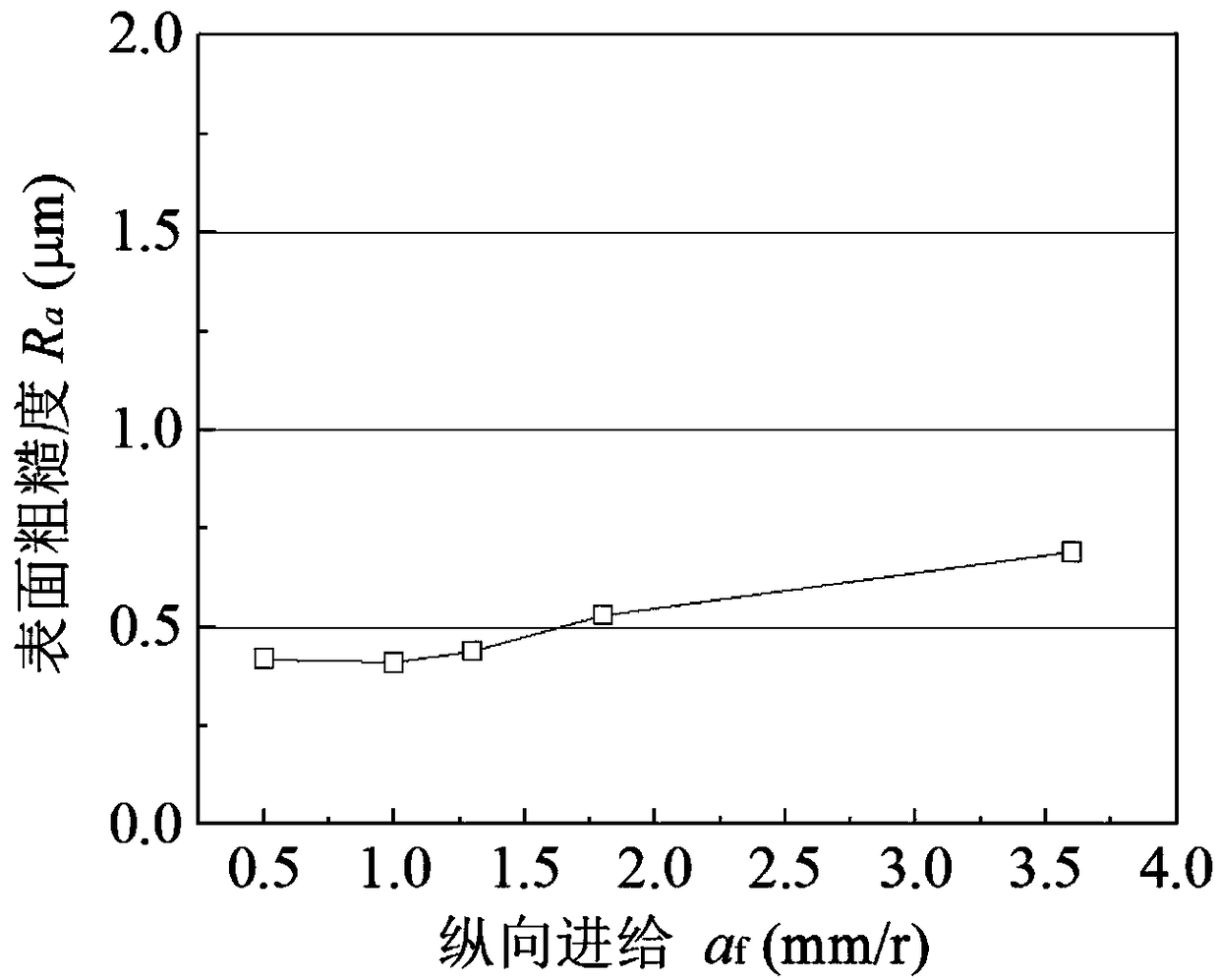

[0052] Step 1.1, through the single factor test method, according to the grinding process parameter domain C of the ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com