Detection tool for air tightness of oil sump

A technology for detecting tooling and oil pans, which is applied in fluid tightness testing, measuring devices, and detecting the appearance of fluid at leak points, etc., can solve the problems of time-consuming and cumbersome oil pan airtightness testing operations, etc. Achieve the effect of consistent pressure, intuitive and convenient observation, and increase production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

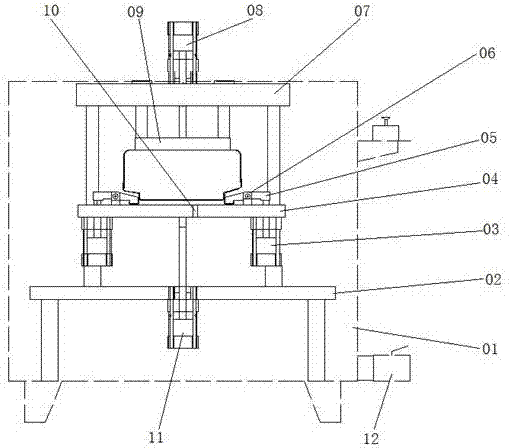

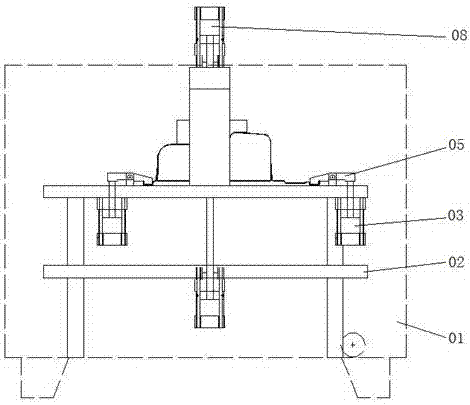

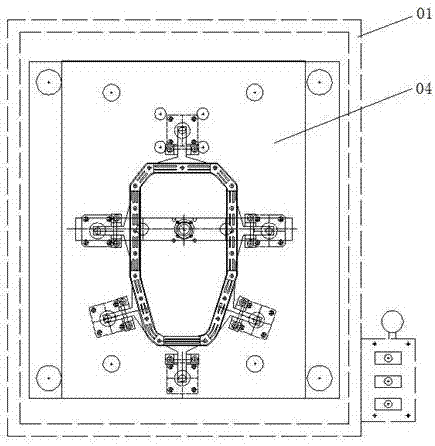

[0024] Such as figure 1 , figure 2 as well as image 3 As shown, the oil pan airtight detection tool includes a detection box 01, a supporting platform 02, a lifting platform 04 and a pressing device. The supporting platform 02 is set in the testing box 01, and the lifting platform 04 is movably connected to the supporting platform. 02, the pressing device is set on the lifting platform 04, the pressing device includes a top pressing device and a side pressing device, the oil pan is placed upside down on the lifting platform 04, and the top pressing device and the side The pressing device is pressed on the lifting platform 04. The side pressing device is composed of a side pressing cylinder 03 and a side pressing block 05. The side pressing cylinder 03 is fixedly connected to the lifting platform 04, and the lifting platform 04 There is a rotating bracket 06 on the top, and the middle part of the side pressing block 05 is rotatably connected to the rotating bracket 06. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com