Novel gas drive two-stage light gas gun piston and additional weight combination device

A two-stage light gas gun, gas-driven technology, applied to the types of weapons, compressed air guns, weapons without explosives, etc., can solve the problem of poor sealing of the front and rear air chambers, poor sealing of the front and rear air chambers, and utilization of the front air chamber Low efficiency and other problems, to achieve the effect of not easy to block the pump tube, enhance the sealing effect, and easy to take out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

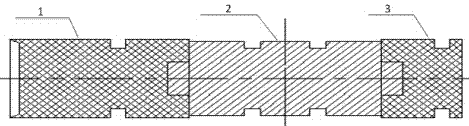

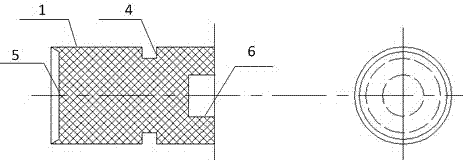

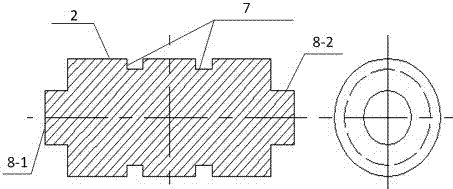

[0025] combine figure 1 Shown: Gas-driven two-stage light gas gun piston and counterweight combination device, which is set as a three-stage structure of nylon 66-tungsten alloy-nylon 66 piston, including: front end nylon 66 1, tungsten alloy counterweight 2, rear end Nylon 66 3; front nylon 66 groove 4, front nylon 66 bell mouth 5, front nylon 66 and counterweight connection groove 6, tungsten alloy counterweight groove 7, tungsten alloy counterweight and front nylon 66 connection protrusion 8- 1; Nylon 66 at the rear end and counterweight connection groove 9, nylon 66 groove at the rear end 10 and tungsten alloy counterweight and nylon 66 rear end connection protrusion 8-2;

[0026] The front-end nylon 661, tungsten alloy count...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com