Frame composed of composite columns and composite beam and construction method of frame

A technology of combining beams and columns, which is applied in the processing of building components, building structures, building materials, etc., can solve the problems of easily damaged joints and complex joints, so as to improve the overall buckling resistance, clear force transmission, Connecting Sophisticated Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

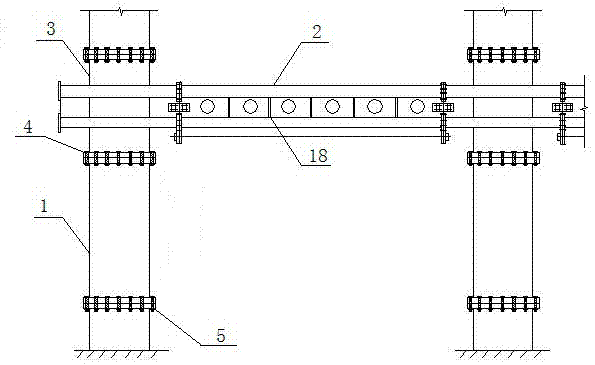

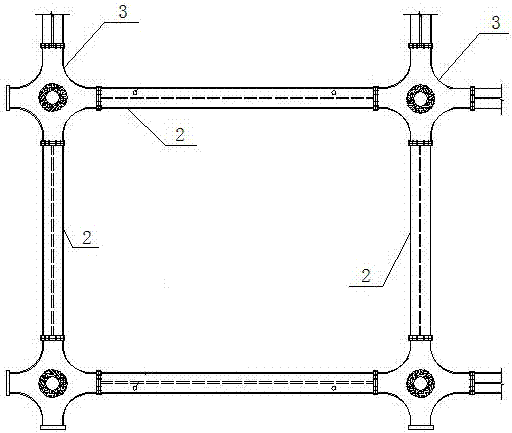

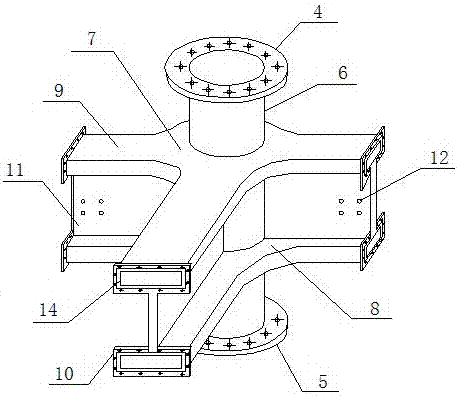

[0041] combine figure 1 , figure 2 , image 3 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 12 , Figure 14 As shown, the frame composed of composite columns and composite beams is composed of composite columns 1 and composite beams 2 connected by nodes 3, composite beams 2 are horizontally arranged between composite columns 1, and nodes 3 are the overall outer casing filled with self-compacting concrete 13 The integral node of the outer jacket includes a node outer tube 6 with an upper connecting ring 4 and a lower connecting ring 5. Both the upper connecting ring 4 and the lower connecting ring 5 are provided with bolt holes 12, and the upper part of the node outer tube 6 has an upper reinforcement The rectangular ring plate 7 has a lower reinforced rectangular ring plate 8 on the lower part, the upper reinforced rectangular ring plate 7 extends horizontally outwards to form an upper node end beam connected with the inner cavity,...

Embodiment 2

[0053] The frame that this composite column composite beam forms differs from Embodiment 1:

[0054] External prestressing tendons 22 are arranged on the lower part of the honeycomb I-beam whose flange is rectangular steel tube concrete through the protruding plate under the beam, and the prestressing tendons 22 may be linear.

[0055] Of course, a steering block 23 with an inner groove can also be arranged on the lower part of the honeycomb-shaped I-beam, and the prestressed tendons 22 are formed in a broken line or curved shape to increase the rigidity of the beam and reduce deformation.

[0056] The construction method of the frame composed of this composite column composite beam:

[0057] Firstly, the materials are cut in the factory according to the design, and all the required steel components are welded and prefabricated, including the segmental outer tube 16 and the segmental inner tube 15 with the connecting rings welded at both ends, and the end beam protruding conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com