Pink sparkling wine and preparation process thereof

A preparation process and technology of sparkling wine, applied in the field of pink sparkling wine and its preparation, can solve the problems of unsuitable taste, sour taste, etc., and achieve the effect of good taste and nutrient composition, refreshing taste and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

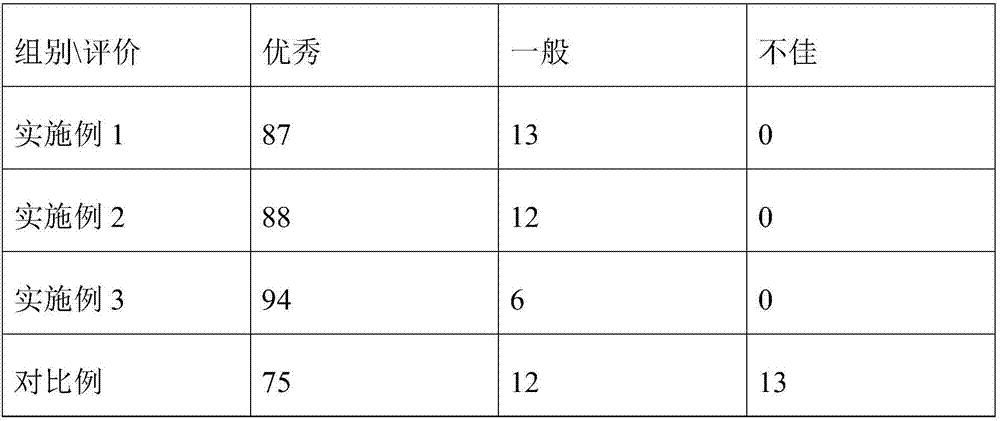

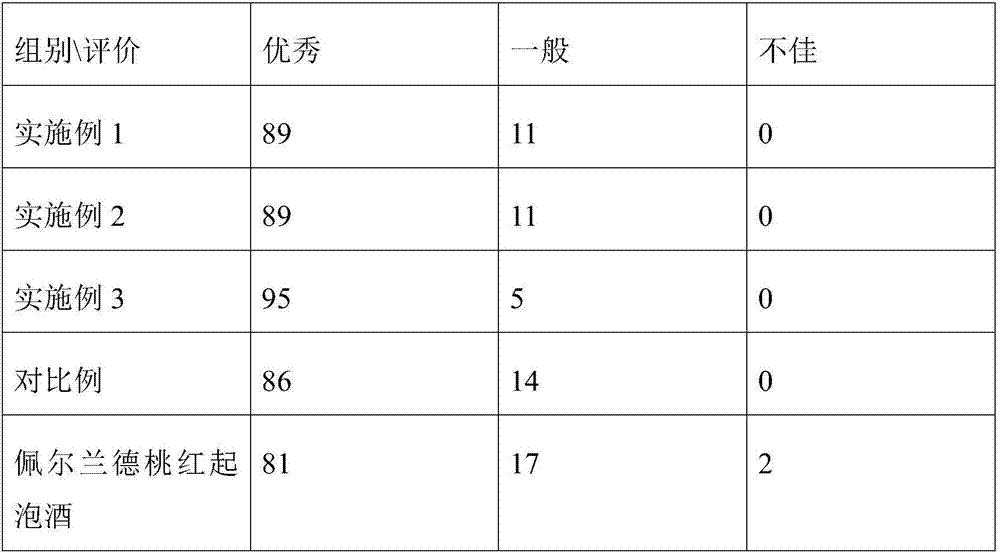

Examples

Embodiment 1

[0034] Prepare Rosé Sparkling Wine

[0035] Harvesting: Grapes are harvested late after they are ripe, so that the glucose level can reach 260g / L.

[0036] Selection: remove the branches and leaves, moldy and rotten fruits and other sundries in the raw materials.

[0037] Squeeze to get the juice: choose a frame press, add sodium metabisulfite (purity 50%) at 100g / ton during the pressing process.

[0038] Clarification: add pectinase at 30g / ton, clarify at natural low temperature (0-6°C) for 3 days, pour the tank and separate the lees.

[0039] Primary fermentation (alcoholic fermentation): Yeast (Nuomo STR) is added to the separated supernatant at a dosage of 250g / ton, and fermented at low temperature and temperature control (13-15°C) for 25 days.

[0040] Stop fermentation: When the alcohol content reaches 10% VOL, lower the temperature to 0-6°C to stop the fermentation.

[0041] Clarification: add 800g of bentonite and 30g of vegetable gum per ton of grape juice, and cla...

Embodiment 2

[0048] Prepare Rosé Sparkling Wine

[0049] Harvesting: Grapes are harvested late after they are ripe, so that the glucose level can reach 260g / L.

[0050] Selection: remove the branches and leaves, moldy and rotten fruits and other sundries in the raw materials.

[0051] Squeeze to get the juice: choose a frame press, add sodium metabisulfite (purity 50%) at 150g / ton during the pressing process.

[0052] Clarification: add pectinase at 50g / ton, clarify at natural low temperature (0-6°C) for 10 days, pour the tank and separate the lees.

[0053] Primary fermentation (alcoholic fermentation): Yeast (Nuomo STR) is added to the separated supernatant at a dosage of 350g / ton, and fermented at low temperature and temperature control (13-15°C) for 30 days.

[0054] Stop fermentation: When the alcohol content reaches 11% VOL, lower the temperature to 0-6°C to stop the fermentation.

[0055] Clarification: add 1200g of bentonite and 50g of vegetable gum per ton of grape juice, and cla...

Embodiment 3

[0062] Prepare Rosé Sparkling Wine

[0063] Harvesting: Grapes are harvested late after they are ripe, so that the glucose level can reach 255g / L.

[0064] Selection: remove the branches and leaves, moldy and rotten fruits and other sundries in the raw materials.

[0065] Squeeze to get the juice: choose a frame press, add sodium metabisulfite (purity 50%) at 120g / ton during the pressing process.

[0066] Clarification: add pectinase at a rate of 40g / ton, clarify at natural low temperature (0-6°C) for one week, and pour the tank to separate the lees.

[0067] Primary fermentation (alcoholic fermentation): Yeast (Nuomo STR) is added to the separated supernatant at a dosage of 300g / ton, and fermented at low temperature and temperature control (13-15°C) for 26 days.

[0068] Stop fermentation: When the alcohol content reaches 10% VOL, lower the temperature to 0-6°C to stop the fermentation.

[0069] Clarification: add 1000g of bentonite and 40g of vegetable gum per ton of grap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com