New applications of waste polystyrene foam plastic

A technology for waste polystyrene and foam plastics, which is applied in the direction of plastic recycling, recycling technology, coating, etc., and can solve the problems of difficult recycling, economic uneconomical, and plastics that cannot be degraded naturally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

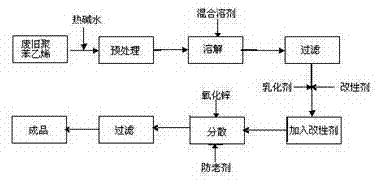

[0006] The present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings.

[0007] see attached image

[0008] The specific steps are: 1) Pre-treat the recycled waste polystyrene foam, add the polystyrene to be cleaned together with hot alkaline water into the reactor, heat and stir thoroughly, and then take out the polystyrene and put it into the clear water pool Stir and clean to achieve the purpose of decontamination; 2) Pulverize with a pulverizer, or manually if the amount is small; 3) Measure a certain proportion of isoamyl acetate, chloroform, and acetone to prepare a mixed solvent. Add a certain amount of pretreated waste polystyrene foam into the prepared mixed solvent at room temperature, and stir to fully dissolve it; 3) After it is completely dissolved, add an appropriate amount of emulsifier dodecylbenzene Sodium sulfonate, modifier, plasticizer dibutyl phthalate 1-3; antifreeze ethylene glycol,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com