Preparation method of cortisone acetate

A technology of cortisone acetate and organic acids, applied in the field of biopharmaceuticals, can solve the problems of complex fermentation process, large amount of waste water, poor selectivity, etc., and achieve the effects of obvious quality and yield, less pollution, and fewer reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

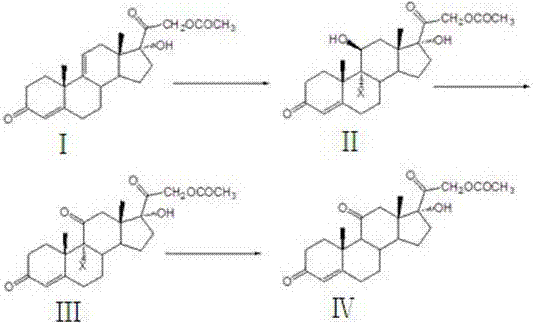

[0014] A preparation method of cortisone acetate, using anadal acetate (compound Ⅰ) corta as a raw material, comprising the following steps:

[0015] A: Addition reaction: under the protection of nitrogen, add anecorta acetate (compound Ⅰ) into methanol and stir to dissolve at 25~30°C, then add perchloric acid and dibromohydantoin in sequence, keep the reaction for more than 5 hours, TLC Detect that there is no remaining raw material, add water for water analysis, filter and wash until neutral, and dry to obtain 11β, 17α, 21-trihydroxy-9α-bromopregna-4-ene-3,20-dione-21-acetate (compound II);

[0016] B: Oxidation reaction:

[0017] Add 11β, 17α, 21-trihydroxy-9α-bromopregna-4-ene-3,20-dione-21-acetate (compound Ⅱ) into acetone under nitrogen protection, and stir at 10~15°C Dissolve, add Jones reagent, react for more than 3 hours, TLC detects that there is no remaining raw material, filter, concentrate under reduced pressure to recover the solvent, filter and wash with water...

Embodiment 1

[0021] A: Addition reaction: Preparation of compound Ⅱ: 11β, 17α, 21-trihydroxy-9α-bromopregna-4-ene-3,20-dione-21-acetate in a reaction flask under nitrogen protection Add 50g of anecortax acetate and 500ml of methanol, stir and dissolve at a controlled temperature of 25~30°C, then add 2ml of perchloric acid and 25g of dibromohydantoin in sequence, keep the reaction for 5 hours, TLC (chloroform:methanol=9:1) detects no Raw material point, add 2000ml of water, water analysis, filter, wash with water until neutral, drain, and dry to get 11β, 17α, 21-trihydroxy-9α-bromopregna-4-ene-3,20-dione- 21-acetate 62.5g, TLC maximum point 0.8%;

[0022] B: Oxidation reaction: Preparation of compound Ⅲ: 11β, 17α, 21-trihydroxy-9α bromopregn-4-ene-3,11,20-trione-21-acetate, added to the reaction bottle under nitrogen protection 11β, 17α, 21-trihydroxy-9α-bromopregna-4-ene-3,20-dione-21-acetate 50g, dichloromethane 500ml, control the temperature at 10~15℃, add Jones reagent 25g, After reac...

Embodiment 2

[0025] A: Addition reaction: Preparation of compound Ⅱ: 11β, 17α, 21-trihydroxy-9α-bromopregna-4-ene-3,20-dione-21-acetate in a reaction flask under nitrogen protection Add 50g of anectostat acetate and 500ml of methanol, stir and dissolve at a controlled temperature of 25~30°C, add 1ml of perchloric acid and 10g of dibromohydantoin in sequence, keep the reaction for 5 hours, TLC (chloroform:methanol=9:1) detects no Raw material point, add 2000ml of water, water analysis, filter, wash with water until neutral, drain, and dry to get 11β, 17α, 21-trihydroxy-9α-bromopregna-4-ene-3,20-dione- 21-Acetate 62.3g, TLC maximum point 0.6%;

[0026] B: Oxidation reaction: Preparation of compound Ⅲ: 11β, 17α, 21-trihydroxy-9α-bromopregna-4-ene-3,11,20-trione-21-acetate in a reaction flask under nitrogen protection Add 11β, 17α, 21-trihydroxy-9α-bromopregna-4-ene-3,20-dione-21-acetate 50g, acetone 500ml, control the temperature at 10~15℃, add Jones reagent 50g, react After more than 3 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com