A surface antibacterial composite coating for a titanium metal and a preparing method thereof

A surface antibacterial and composite coating technology, which is applied in the field of materials science and nanomaterials, can solve the problem of single function, and achieve the effects of promoting bone formation, improving biocompatibility, and improving antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a polylactic acid / nanometer silver / zinc oxide nanorod long-acting antibacterial composite coating on the surface of a titanium implant, characterized in that it comprises the following steps:

[0032] step one,

[0033] A titanium metal disc with a diameter of 6 mm and a thickness of 2.5 mm was polished step by step with sandpaper, then ultrasonically cleaned in acetone, deionized water, and absolute ethanol in sequence, and dried for use.

[0034] step two,

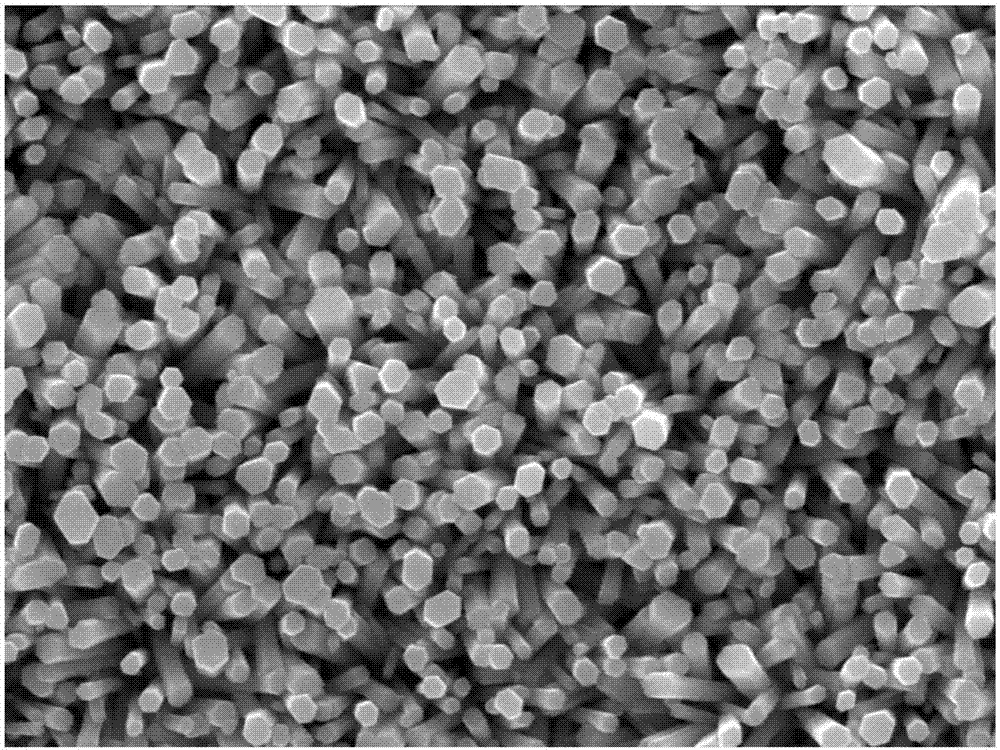

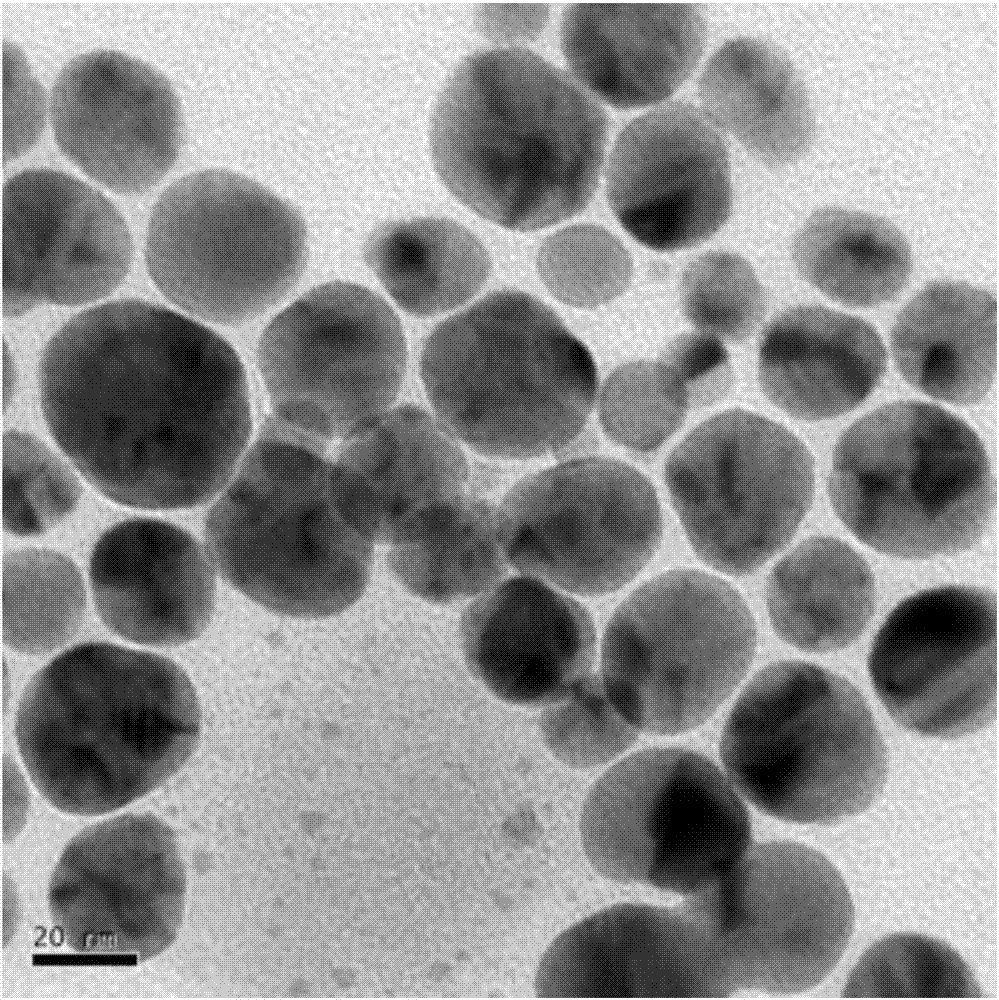

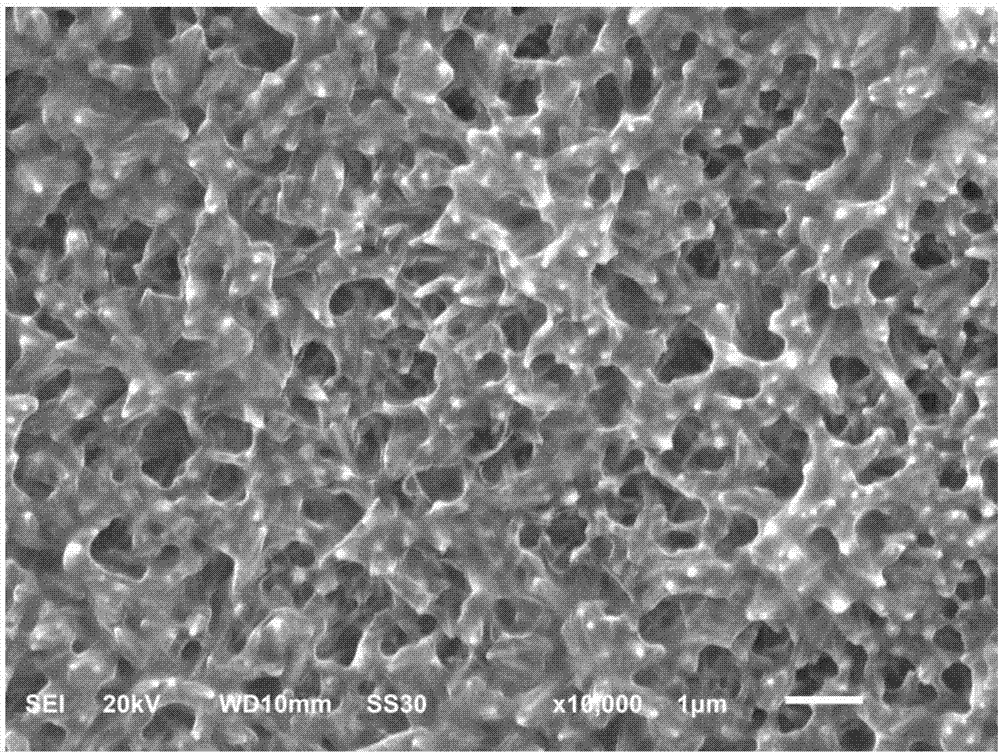

[0035] Mix and dissolve 4.1 g of zinc acetate and 1.14 g of ethanolamine in 50 mL of absolute ethanol, stir at room temperature for 4 hours to obtain a mixed solution, and then spin-coat 30 μl of the mixed solution onto the surface of the polished titanium sheet, and the spin-coater is controlled at 600rpm for 15 seconds, 5000rpm for 30 seconds, this process was repeated five times; put the spin-coated titanium sheet in a muffle furnace for 60 minutes at 500°C, and cool at room temperature;...

Embodiment 2

[0041] A method for preparing a polylactic acid / nanometer silver / zinc oxide nanorod long-acting antibacterial composite coating on the surface of a titanium implant, characterized in that it comprises the following steps:

[0042] step one,

[0043] A titanium metal disc with a diameter of 6 mm and a thickness of 2.5 mm was polished step by step with sandpaper, then ultrasonically cleaned in acetone, deionized water, and absolute ethanol in sequence, and dried for use.

[0044] step two,

[0045]Mix and dissolve 3.8 g of zinc acetate and 0.9 g of ethanolamine in 50 mL of absolute ethanol, stir at room temperature for 4 hours to obtain a mixed solution, and then spin-coat 30 μl of the mixed solution onto the surface of the polished titanium sheet, and the spin coater is controlled at 600rpm for 15 seconds, 5000rpm for 30 seconds, repeat this process five times; put the spin-coated titanium sheet in a muffle furnace for 60 minutes at 500°C, and cool at room temperature; g hexa...

Embodiment 3

[0051] A method for preparing a polylactic acid / nanometer silver / zinc oxide nanorod long-acting antibacterial composite coating on the surface of a titanium implant, characterized in that it comprises the following steps:

[0052] step one,

[0053] A titanium metal disc with a diameter of 6 mm and a thickness of 2.5 mm was polished step by step with sandpaper, then ultrasonically cleaned in acetone, deionized water, and absolute ethanol in sequence, and dried for use.

[0054] step two,

[0055] Mix and dissolve 4.0 g of zinc acetate and 1.0 g of ethanolamine in 50 mL of absolute ethanol, stir at room temperature for 4 hours to obtain a mixed solution, and then spin-coat 30 μl of the mixed solution onto the surface of the polished titanium sheet, and the spin-coater is controlled at 600rpm for 15 seconds, 5000rpm for 30 seconds, this process was repeated five times; the spin-coated titanium sheet was put into a muffle furnace for 60 minutes at 500°C, and cooled at room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com