Rotary air film cooling temperature gradient thermal mechanical fatigue test system

A technology of thermomechanical fatigue and temperature gradient, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problem of inability to truly reproduce the temperature gradient field of the gas film cooling type of the test piece, the temperature field cannot achieve the accurate expected effect, and the temperature control system High cost and other issues, to achieve accurate control of cooling air flow, simple and easy operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing, the present invention is further described:

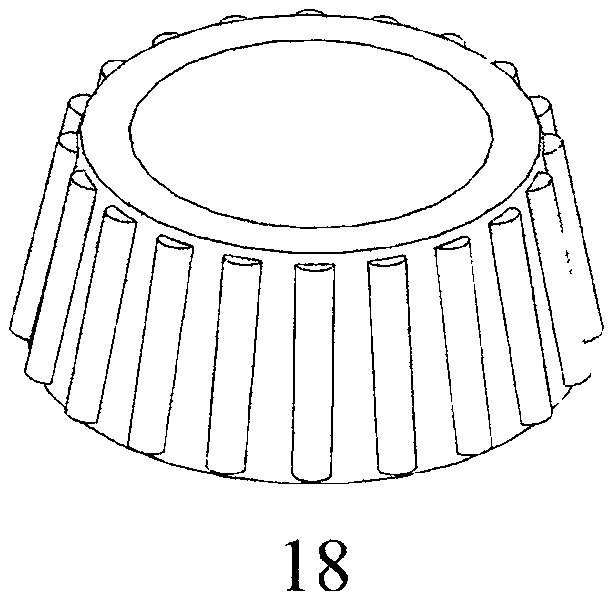

[0044] In conjunction with the accompanying drawings, a further description will be given of the technical solution adopted by a rotatable hollow air-cooled temperature gradient test system of the present invention to realize the temperature gradient generated by simulating the rotation of the test piece and the friction of air. The structure of the thermomechanical fatigue testing machine is as follows: figure 1 shown.

[0045] Under the test conditions, the mechanical load of the specimen thermomechanical fatigue test system is generated by the fatigue testing machine, and the tensile load is applied through the loading system to control the upper and lower clamps 4 and 17, and is transmitted to the specimen 21 through the high temperature resistant upper and lower clamps 15 and 8. The type is controlled by the thermomechanical fatigue testing machine load spectrum. The upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com