Preparation method and application of bone marrow protein

A protein and bone marrow technology, applied in the field of bone marrow protein preparation, can solve problems such as environmental pollution, environmental pressure, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

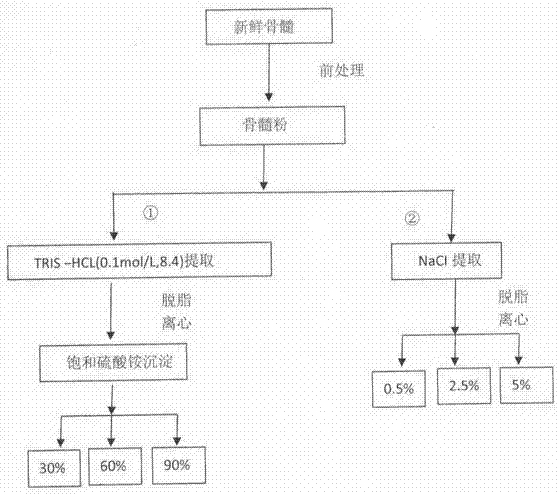

Embodiment 1

[0035] Buffer extraction:

[0036] a. Take fresh bone marrow, wash it 3 times, remove the bones and blood, cut it into small pieces, add liquid nitrogen at a weight ratio of 1:5, and grind it repeatedly for 3 times to obtain bone marrow powder, and store it in a low-temperature refrigerator for later use;

[0037] b. Take 100 g of the crushed bone marrow powder obtained in step a, add 0.1 mol / L tris hydrochloride with a weight ratio of 1:10, pH=8.4 buffer solution, and set intensive constant temperature heating at a temperature of 40°C Reflux on a magnetic stirrer and extract repeatedly 2 times until no precipitate is seen to obtain the total extract;

[0038] C, the total extraction that step b obtains is degreased by the sherwood oil of 1:6 according to the solid-liquid ratio, repeats 2-3 times, collects the lower layer extract;

[0039] d. Centrifuge the lower layer extract obtained in step c at 12,000 rpm at 4° C. for 10 minutes, and take the supernatant to obtain a crude...

Embodiment 2

[0043] Inorganic salt solvent extraction:

[0044] a. Take fresh bone marrow, wash it 3 times, remove the bones and blood, cut it into small pieces, add liquid nitrogen at a weight ratio of 1:5, and grind it repeatedly for 3 times to obtain bone marrow powder, and store it in a low-temperature refrigerator for later use;

[0045] b. Take 3 equal portions of 100 g of the pulverized bone marrow sample in step a. In each sample, the ratio of solid to liquid is 1:5, and the mass fraction is added respectively to 0.5%, 2.5% and 5% sodium chloride solution for extraction. Put it on an intensive constant temperature heating magnetic stirrer at a temperature of 40°C and repeatedly extract it twice until no sediment is found under the flat bottom. The reflux time is 3 hours. Filter the extract, add sodium chloride solution to the unfiltered part, and filter , combined filtrate;

[0046] C, the merging filtrate obtained by step b is degreased with a material-to-liquid ratio of 1:4 petr...

Embodiment 3

[0050] Buffer extraction:

[0051] a. Take fresh bone marrow, wash it 3 times, remove the bone and blood, cut it into small pieces, add liquid nitrogen to pulverize according to the weight ratio of 1:5, and pulverize it repeatedly 4 times to obtain bone marrow pulverized powder, and store it in a low-temperature refrigerator for later use;

[0052] b. Take 100 g of the crushed bone marrow powder obtained in step a, add tris hydrochloric acid with a weight ratio of 1:10, 0.1 mol / L, pH=8.4 buffer solution, and set an intensive constant temperature heating magnetic force at a temperature of 40°C Reflux on the mixer and extract repeatedly 3 times until no precipitate is seen to obtain the total extract;

[0053] c, the total extraction that step b obtains is degreased by the n-hexane of 1:6 according to the solid-liquid ratio, repeats 2-3 times, and collects the lower layer extract;

[0054] d. Centrifuge the lower layer extract obtained in step c at 12,000 rpm at 4° C. for 10 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com