A kind of preparation method of chickpea polypeptide part and application thereof

A chickpea polypeptide, chickpea technology, applied in the preparation method of peptides, chemical instruments and methods, medical preparations containing active ingredients, etc., can solve problems such as toxic and side effects, achieve antioxidant and hypoglycemic activity, Enhance humoral immunity and systemic immunity, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

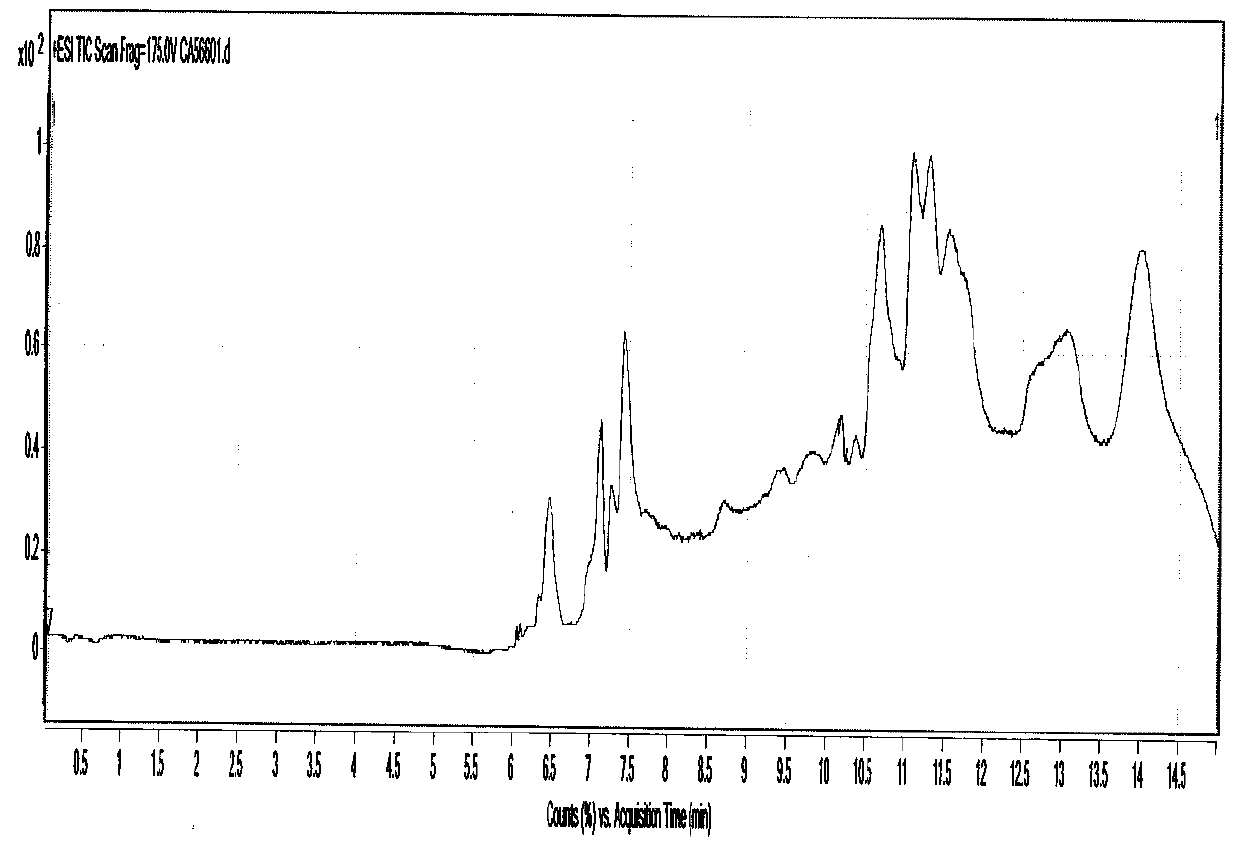

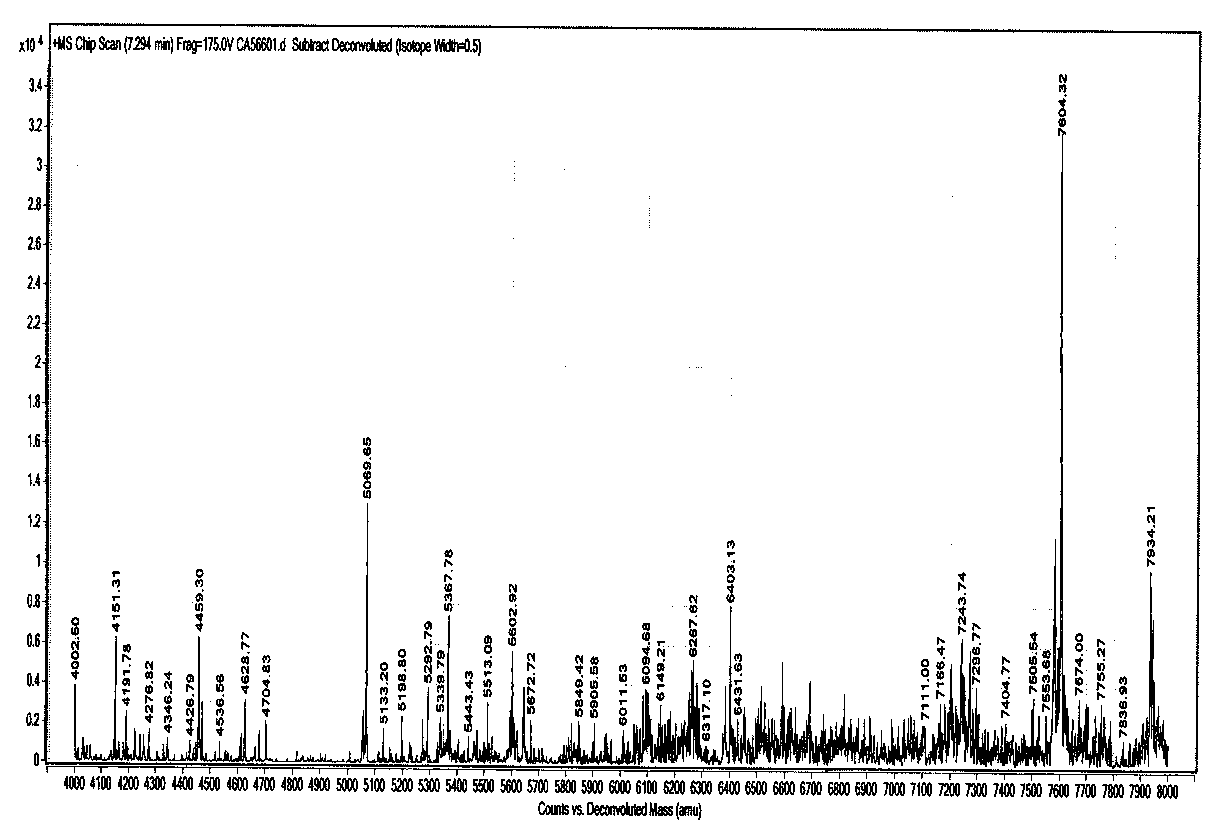

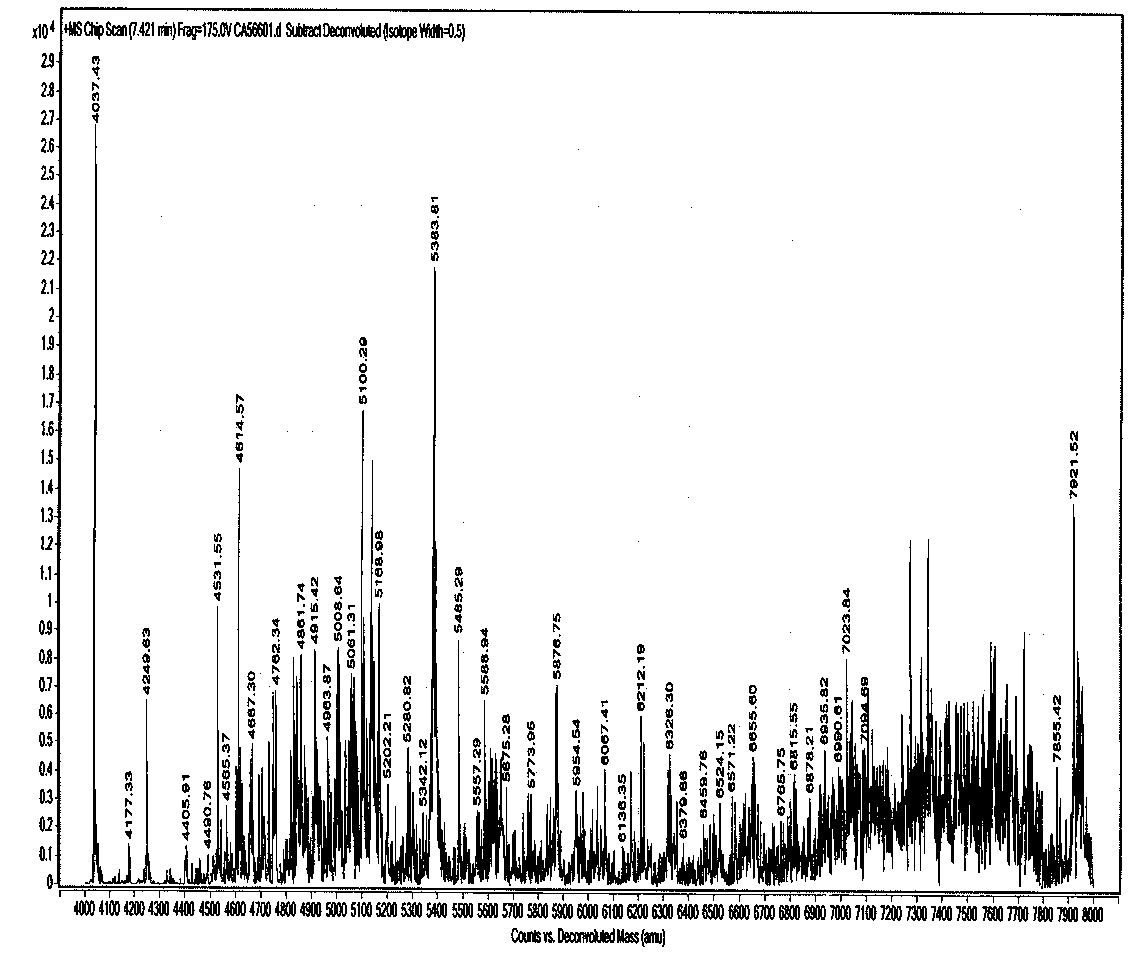

Image

Examples

Embodiment 1

[0042] Preparation of chickpea watercress polypeptide powder:

[0043] a. Take the watercress after germination and tooth removal of the chickpea, rinse it with water 3 times until it is completely clean, filter with gauze respectively, combine the cleaned chickpea and watercress, dry at low temperature, control the temperature at 40 ° C, and drench the dried chickpea and watercress. Douban was pulverized by a pulverizer, and the pulverized particle size was 200 mesh. According to the material-liquid weight ratio of 1:5, petroleum ether was added, stirred at room temperature for 1 hour, and repeatedly extracted 3 times until no oil was extracted, suction filtration, and combined Precipitation, naturally dried until there is no petroleum ether solvent residue, to obtain degreasing chickpea flour;

[0044] b. Add 50% edible ethanol to the fully defatted chickpea flour in step a, with a solid-liquid ratio of 1:5, stir and extract at room temperature for 2 hours, extract 3 times e...

Embodiment 2

[0048] a. Take the chickpea dregs after extracting the small molecular compounds with a dry organic solvent, pulverize, the pulverized particle size is 200 mesh, add petroleum ether according to the material-liquid weight ratio of 1:5, stir at room temperature for 2 hours, and repeatedly extract 4 times Until no oil is extracted, suction filtration, combined precipitation, and natural drying until no petroleum ether solvent remains to obtain degreasing chickpea flour;

[0049]b. Add 50% edible ethanol to the fully defatted chickpea flour in step a, with a solid-liquid ratio of 1:5, stir and extract at room temperature for 3 hours, extract 4 times each time, filter under reduced pressure, and combine Extracting solution, separating impurities, and obtaining crude polypeptide extraction solution for subsequent use;

[0050] c. Dilute the crude polypeptide extraction solution obtained in step b to 20% ethanol concentration with distilled water, and apply 20% ethanol to the dilute...

Embodiment 3

[0053] Preparation of chickpea watercress polypeptide powder:

[0054] a. Take the watercress after germination and tooth removal of the chickpea, rinse it with water 3 times until it is completely clean, filter with gauze respectively, combine the cleaned chickpea and watercress, dry at low temperature, control the temperature at 40 ° C, and drench the dried chickpea and watercress. Douban was pulverized by a pulverizer, and the pulverized particle size was 200 meshes. Petroleum ether was added according to the material-liquid weight ratio of 1:5, stirred at room temperature for 2 hours, repeatedly extracted 4 times until no oil was extracted, suction filtered, and combined Precipitation, naturally dried until there is no petroleum ether solvent residue, to obtain degreasing chickpea flour;

[0055] b. Add 50% edible ethanol to the fully defatted chickpea flour in step a, with a solid-liquid ratio of 1:5, stir and extract at room temperature for 3 hours, extract 4 times each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com