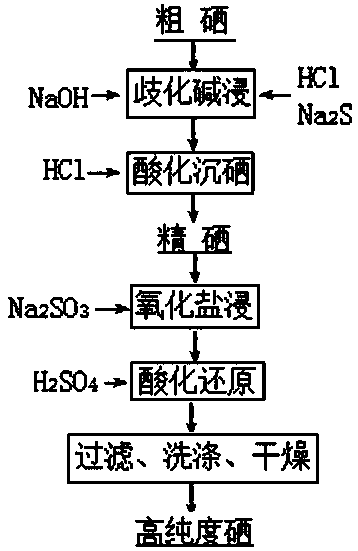

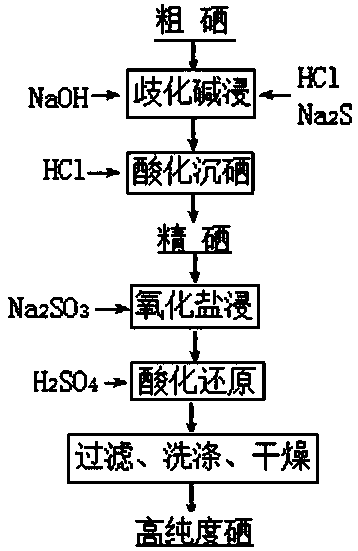

A method for preparing high-purity selenium by a crude selenium wet method

A high-purity, wet purification technology, applied in the direction of element selenium/tellurium, etc., can solve the problems of high-purity selenium having no commonality, low recovery rate, and difficulty in finding, so as to shorten the selenium purification process, reduce production costs, and reduce limitations sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) First weigh 200g of high-impurity crude selenium after drying, slurry it with 200ml of water, turn on the stirring, and slowly add 500ml of sodium hydroxide solution with a mass fraction of 35%, and the leaching time is 1.5h to ensure that the crude selenium is completely dissolved and leached ;

[0031] (2) Use hydrochloric acid with a mass fraction of 5% to adjust the pH of the alkaline infusion to 6.8, then add 100 g of sodium sulfide, stir and mix, and let stand for 1 hour to filter and remove impurities to obtain the alkaline infusion;

[0032] (3) Continue to adjust the pH to 1.2 with hydrochloric acid with a mass fraction of 10% in the alkaline immersion solution, age for 2.5 hours, take the supernatant to detect the selenium content in the solution (≤0.15g / l), the selenium precipitation is complete, and the solid-liquid separation obtains the selenium selenium;

[0033] (4) Oxidatively leaching refined selenium with 40% sodium sulfite solution, controlling ...

Embodiment 2

[0036] (1) First, 260g of high-impurity crude selenium containing 15% water is slurried with 300ml of water, turned on and stirred, and slowly added to 500ml of sodium hydroxide solution with a mass fraction of 40%, and the leaching time is 2 hours to ensure that the crude selenium is completely dissolved and leached;

[0037] (2) Use hydrochloric acid with a mass fraction of 10% to adjust the pH of the alkaline immersion solution to 7.0, then add 110g of sodium sulfide, stir and mix, and let it stand for 1 hour to filter and remove impurities to obtain the alkaline immersion solution;

[0038] (3) Use hydrochloric acid with a mass fraction of 15% to adjust the pH to 1.0 in the alkaline immersion solution, stir evenly, age for 3.0 hours, take the supernatant to detect the selenium content in the solution (≤0.15g / l), the selenium precipitation is complete, solid liquid separation to obtain refined selenium;

[0039] (4) Oxidatively leaching fine selenium with 45% sodium sulfite...

Embodiment 3

[0042] (1) First, 300g of high-impurity coarse selenium with 20% water content is mixed with 400ml of water into a slurry, and 500ml of 45% sodium hydroxide solution is added in small amounts to the slurry of coarse selenium several times, and stirred while adding, the reaction The time is 2.5h to ensure that the crude selenium is completely dissolved and leached;

[0043] (2) Use hydrochloric acid with a mass fraction of 15% to adjust the pH of the alkaline immersion solution to 7.0, then add 120g of sodium sulfide, stir and mix, and let it stand for 1 hour to filter and remove impurities to obtain the alkaline immersion solution;

[0044] (3) Continue to adjust pH to 1.0 with hydrochloric acid with a mass fraction of 20% in the alkaline immersion solution. After stirring evenly, age for 3.0 hours, take the supernatant to test the selenium content in the solution (≤0.15g / l), the selenium precipitation is complete, solid liquid separation to obtain refined selenium;

[0045] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com