Method for separating and purifying rhodium in high-iron rhodium-containing feed liquid

A purification method and material liquid technology, which is applied in the field of comprehensive utilization of resources, can solve the problems of high cost and low recovery rate, and achieve the effects of avoiding losses, improving direct recovery rate, and shortening the purification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

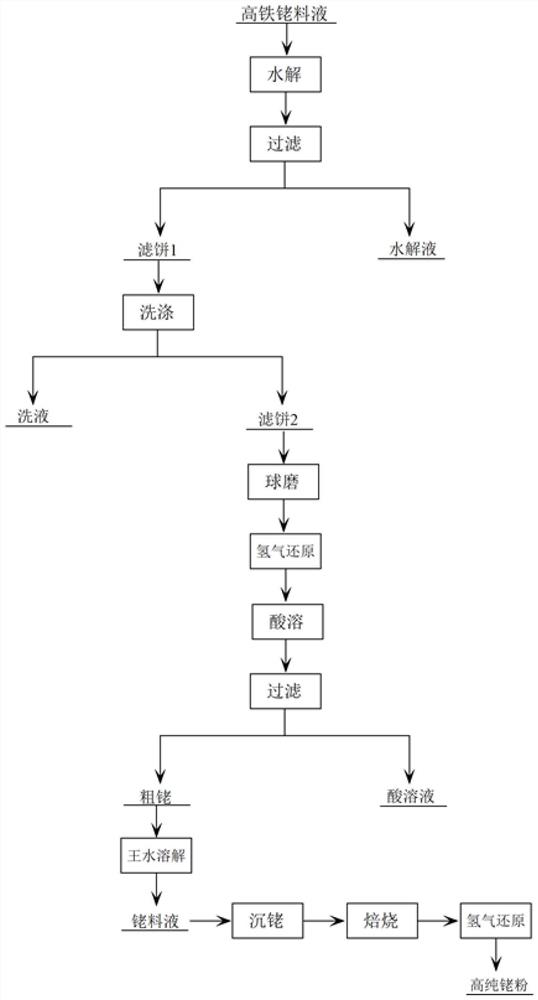

Method used

Image

Examples

Embodiment 1

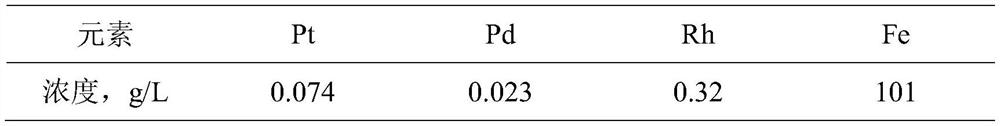

[0034] The composition of a certain feed liquid is as shown in Table 1:

[0035] Table 1 Chemical composition of a feed liquid

[0036]

[0037] (1) Adopting continuous hydrolysis method, high-iron rhodium-containing material liquid and liquid caustic soda are simultaneously added in the reactor, the pH of the material in the control reactor is 3.5, the temperature in the control reactor is 60°C, and the stirring speed in the reactor is 200rpm After the high-iron rhodium-containing material liquid is all added to the reactor, continue to add liquid alkali to adjust the pH to 8 in the reactor, and maintain the pH in the reactor to be 8 to 1h. After the reaction is completed, the material in the reactor is filtered. At this time, the rhodium , iron and other base metal ions all form hydroxide precipitates, obtain the first filter cake 1 and hydrolyzate after filtration, platinum, palladium, rhodium, iron content are all at 0.1ppm in the hydrolyzate, platinum palladium rhodium...

Embodiment 2

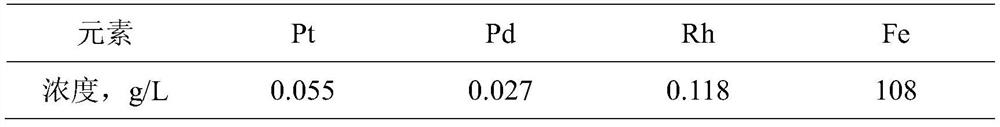

[0046] The composition of a certain feed liquid is as shown in Table 2:

[0047] Table 2 Chemical Composition of a Feed Liquid

[0048]

[0049] (1) Adopting continuous hydrolysis method, high-iron rhodium-containing material liquid and liquid caustic soda are simultaneously added in the reactor, the pH of the material in the control reactor is 3.7, the temperature in the control reactor is 70°C, and the stirring speed in the reactor is 300rpm After the high-iron rhodium-containing material liquid is all added to the reactor, continue to add liquid alkali to adjust the pH to 8.2 in the reactor, maintain the pH in the reactor to be 8.2 to 1.2h, and filter the material in the reactor after the reaction is completed. Rhodium, iron and other base metal ions all form hydroxide precipitates, and after filtration, the first filter cake 1 and hydrolyzate are obtained. The content of platinum, palladium, rhodium and iron in the hydrolyzate is all below 0.1 mg / L, and completely preci...

Embodiment 3

[0058] The composition of a certain feed liquid is as shown in Table 3:

[0059] Table 3 chemical composition of a feed liquid

[0060]

[0061] (1) Adopt continuous hydrolysis method, add high-iron rhodium-containing material liquid and liquid caustic soda simultaneously in the reactor, control the pH of the material in the reactor to be 4.0, control the temperature in the reactor to be 80°C, and the stirring speed in the reactor to be 400rpm After the high-iron rhodium-containing material liquid is all added to the reactor, continue to add liquid alkali to adjust the pH to 8.5 in the reactor, maintain the pH in the reactor to be 8.5 to 1.5h, and filter the material in the reactor after the reaction is completed. Rhodium, iron and other base metal ions all form hydroxide precipitates, and after filtration, the first filter cake 1 and hydrolyzate are obtained. The content of platinum, palladium, rhodium and iron in the hydrolyzate is all below 0.1 mg / L, and completely preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com