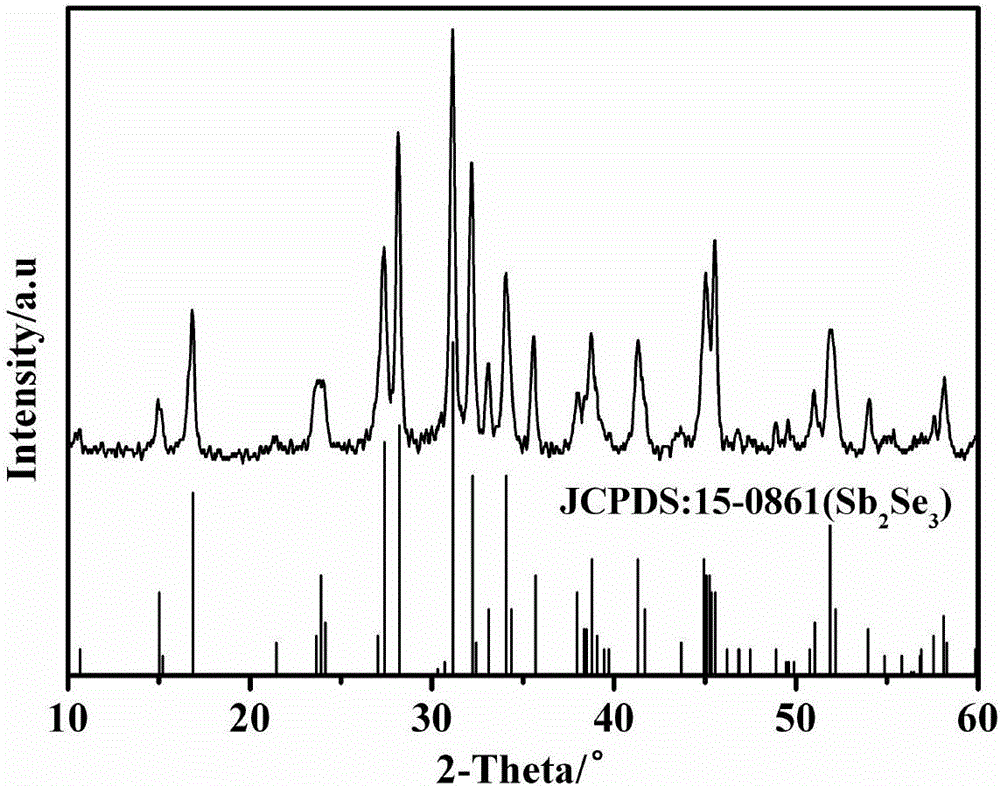

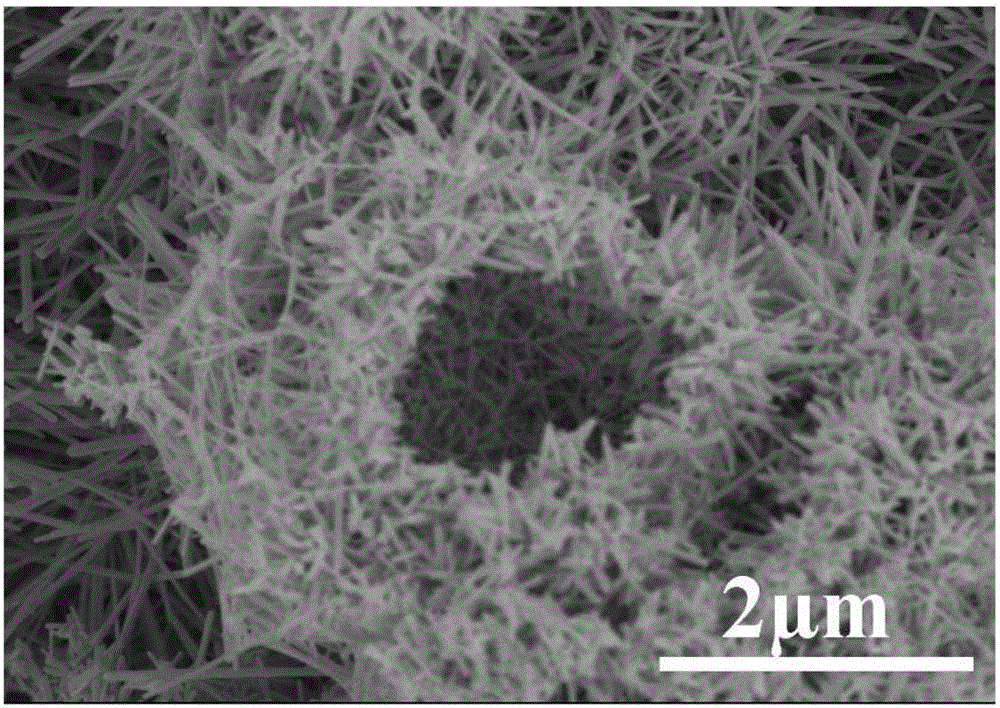

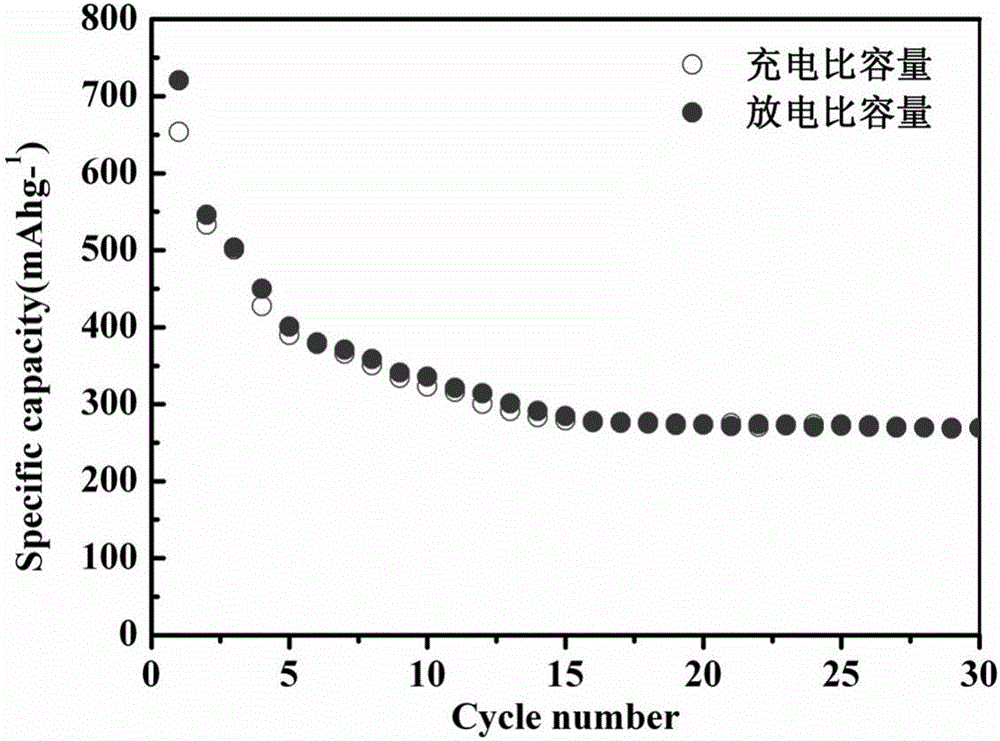

Preparation method of nest-like Sb2Se3 electrode material for sodium ion battery negative electrode

A technology for sodium ion batteries and electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc. , High electrochemical capacity, short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]1) Add 0.675 g of antimony potassium tartrate into 50 mL of deionized water, and magnetically stir until the antimony potassium tartrate is completely dissolved to obtain a mixed solution A, the stirring speed is 500 r / min, and the stirring time is 20 min;

[0027] 2) Disperse 0.2369g of selenium powder in 3ml of hydrazine hydrate (50% by mass), stir magnetically for 40min (rotating speed is 500r / min, stirring temperature is 70°C) to obtain mixed solution B;

[0028] 3) Add the mixed solution B to the mixed solution A dropwise to obtain the mixed solution C. The mixed liquid C was ultrasonicated for 90min (ultrasonic power is 80W, ultrasonic temperature is 70°C), and then transferred to a polytetrafluoroethylene hydrothermal kettle, and the polytetrafluoroethylene hydrothermal kettle was placed in a homogeneous reactor (Yantai Keli Chemical Industry Co., Ltd. Equipment Co., Ltd., KLJX-8A) at a temperature of 120 ° C for 24 h, naturally cooled to room temperature after th...

Embodiment 2

[0032] 1) Add 0.6759 g of antimony potassium tartrate into 60 mL of deionized water, and stir magnetically until the antimony potassium tartrate is completely dissolved to obtain the mixed solution A, the stirring speed is 500 r / min, and the stirring time is 20 min;

[0033] 2) Disperse 0.2369g of selenium powder in 5ml of hydrazine hydrate (50% by mass), and ultrasonicate for 7 minutes (ultrasonic power is 120W; ultrasonic temperature is 40°C) to obtain the mixed solution B;

[0034] 3) Add the mixed solution B to the mixed solution A dropwise to obtain the mixed solution C. The mixed liquid C was magnetically stirred for 3h (rotating speed: 500r / min, stirring temperature: 70°C), then transferred to a polytetrafluoroethylene hydrothermal kettle, and the polytetrafluoroethylene hydrothermal kettle was placed in a homogeneous reactor (Yantai Keli Chemical Equipment Co., Ltd., KLJX-8A) at 140 ° C for 18 h, naturally cooled to room temperature after the reaction, and washed sever...

Embodiment 3

[0038] 1) Add 0.7322 g of antimony potassium tartrate into 70 mL of deionized water, and stir magnetically until the antimony potassium tartrate is completely dissolved to obtain a mixed solution A; the stirring speed is 500 r / min, and the stirring time is 20 min;

[0039] 2) Disperse 0.2566g of selenium powder in 7ml of hydrazine hydrate (50% by mass), and stir magnetically for 20min (rotating speed: 700r / min, stirring temperature: 50°C) to obtain mixed solution B;

[0040] 3) Add the mixed solution B to the mixed solution A drop by drop to obtain the mixed solution C. The mixed solution C was ultrasonicated for 60 minutes (ultrasonic power: 100W; ultrasonic temperature: 50°C) and then transferred to a polytetrafluoroethylene hydrothermal kettle, which was placed in a homogeneous reactor (Yantai Keli Chemical Equipment Co., Ltd. Co., Ltd., KLJX-8A) at a temperature of 150 ° C for 12 hours, after the reaction was completed, it was naturally cooled to room temperature, and wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com