A kind of preparation method of metal organic compound negative electrode material

A technology of organic compounds and negative electrode materials, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of high average working voltage, poor cycle stability, complicated preparation methods, etc., and achieve low average working voltage, low cost, and easy preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The invention relates to a metal-organic compound negative electrode material and a preparation method thereof, belonging to a novel high-capacity, long-life power type, high energy density, and high power density lithium-ion battery metal-organic compound negative electrode material and a low-cost large-scale one-time preparation method thereof.

[0030] The technical scheme of the present invention utilizes metal inorganic salt or organic salt as metal source, uses ethylene glycol, propylene glycol, butanediol and their derivative solvents and organic component sources, and then prepares nanostructure metal organic complex negative electrode material through solvothermal reaction once . Its preparation steps are as follows:

[0031] (1) weigh 0.02mol bismuth nitrate, measure 0.02mol tetrabutyl titanate;

[0032] (2) Measure 100ml ethylene glycol;

[0033] (3) Gradually add the weighed bismuth nitrate and tetrabutyl titanate to the measured ethylene glycol with the a...

Embodiment 2

[0038](1) Weigh 0.01mol antimony acetate, measure 0.005mol tetrabutyl titanate;

[0039] (2) Measure 100ml ethylene glycol;

[0040] (3) Gradually add the weighed antimony acetate and tetrabutyl titanate into the measured ethylene glycol with the assistance of magnetic stirring, stir at a constant speed to completely dissolve and then continue stirring for 1 hour to obtain 0.15molL -1 Metal salt glycol solution;

[0041] (4) 0.15molL prepared in step 3 -1 The metal glycol solution is transferred to a polytetrafluoroethylene container and sealed in a stainless steel solvothermal reaction kettle for solvothermal reaction;

[0042] (5) Place the reaction kettle in a heating furnace, and conduct a solvothermal reaction at 150° C. for 16 hours;

[0043] (6) Wash the solvothermal product obtained in step 5 with a large amount of ethanol for 6 times, and dry it at 90° C. to finally obtain a pure-phase antimony titanium glycol (SbTiEG) metal organic compound negative electrode mate...

Embodiment 3

[0045] (1) weigh 0.01mol tin dichloride, measure 0.01mol tetrabutyl titanate;

[0046] (2) Measure 100ml ethylene glycol;

[0047] (3) Gradually add the weighed tin dichloride and tetrabutyl titanate to the measured ethylene glycol with the assistance of magnetic stirring, stir at a constant speed to completely dissolve and then continue stirring for 2 hours to obtain 0.2molL - 1 Metal salt glycol solution;

[0048] (4) 0.2molL- 1 The metal glycol solution is transferred to a polytetrafluoroethylene container and sealed in a stainless steel solvothermal reaction kettle for solvothermal reaction;

[0049] (5) Place the reaction kettle in a heating furnace, and conduct a solvothermal reaction at 120° C. for 6 hours;

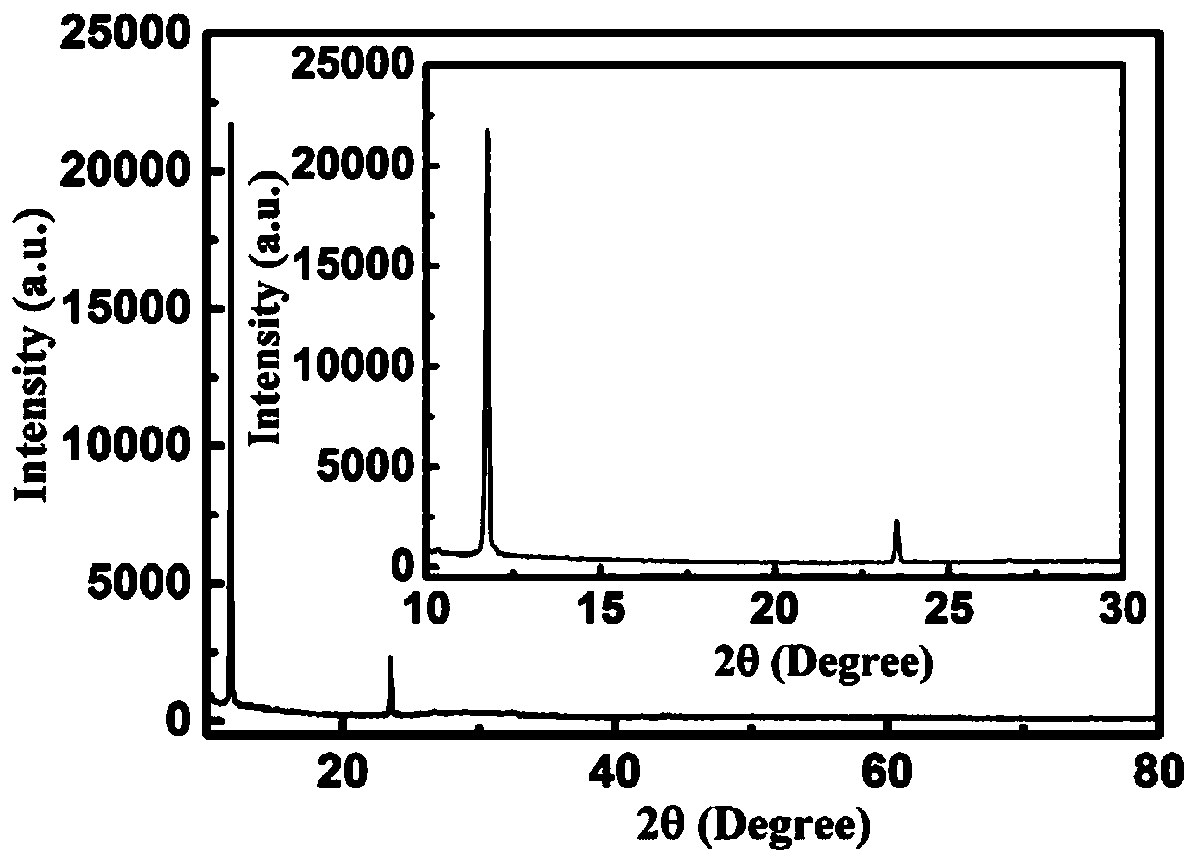

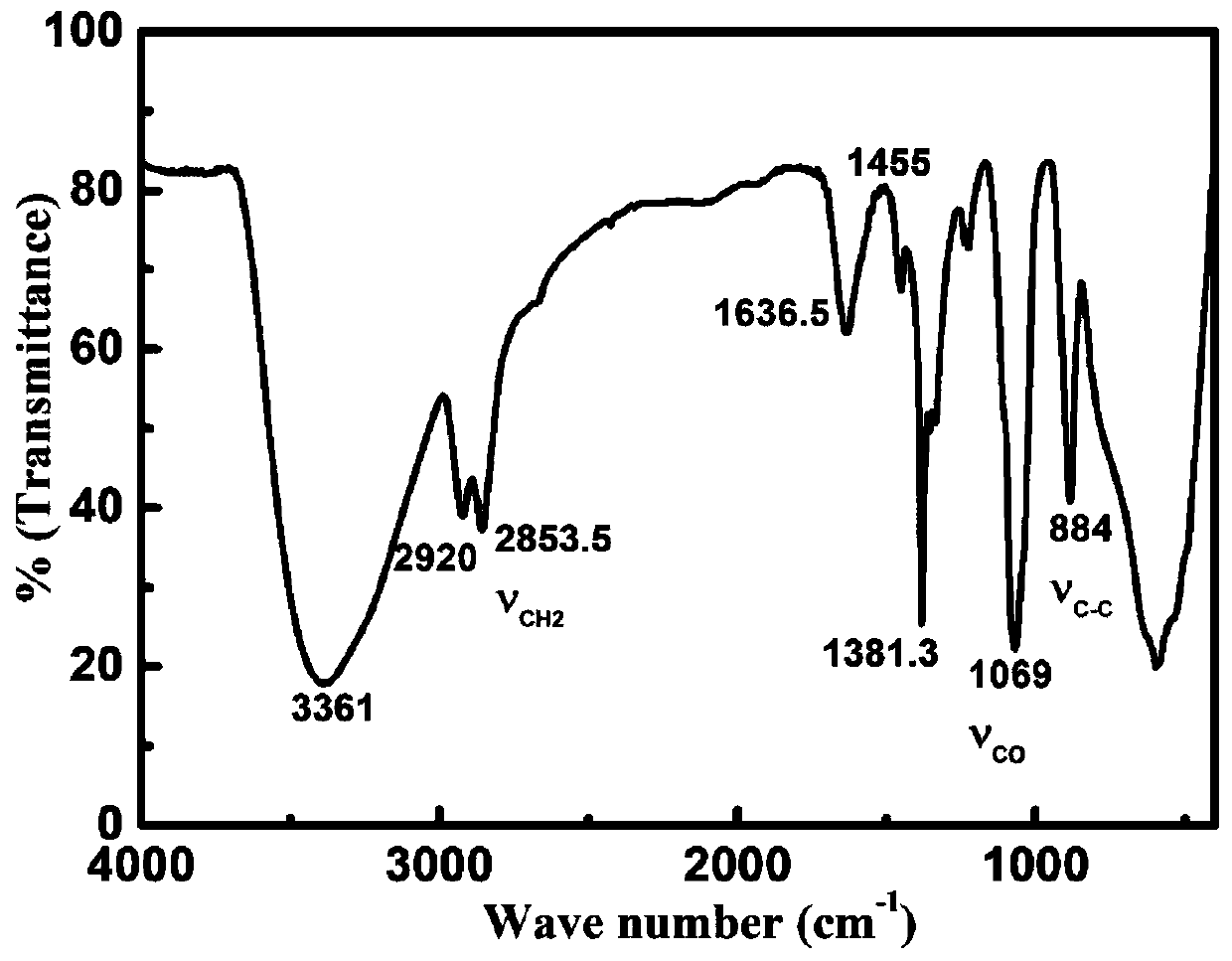

[0050] (6) Wash the solvothermal product obtained in step 5 with a large amount of ethanol three times, and dry it at 90° C. to finally obtain a pure-phase tin-titanium glycol (SnTiEG) metal organic compound negative electrode material. The obtained SnTiEG is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com