A Double Heat Exchange Chamber Grain Drying Hot Air Stove

A technology of heat exchange chamber and hot blast stove, which is applied in drying, drying machine, grain drying, etc. It can solve the problems of low automation degree of grain drying hot blast stove, shortening the life of furnace heat exchanger, large fluctuation of output hot blast temperature, etc. problems, to achieve the effect of reducing heat transpiration, improving heat transfer efficiency and reliability, and small fluctuations in hot air output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

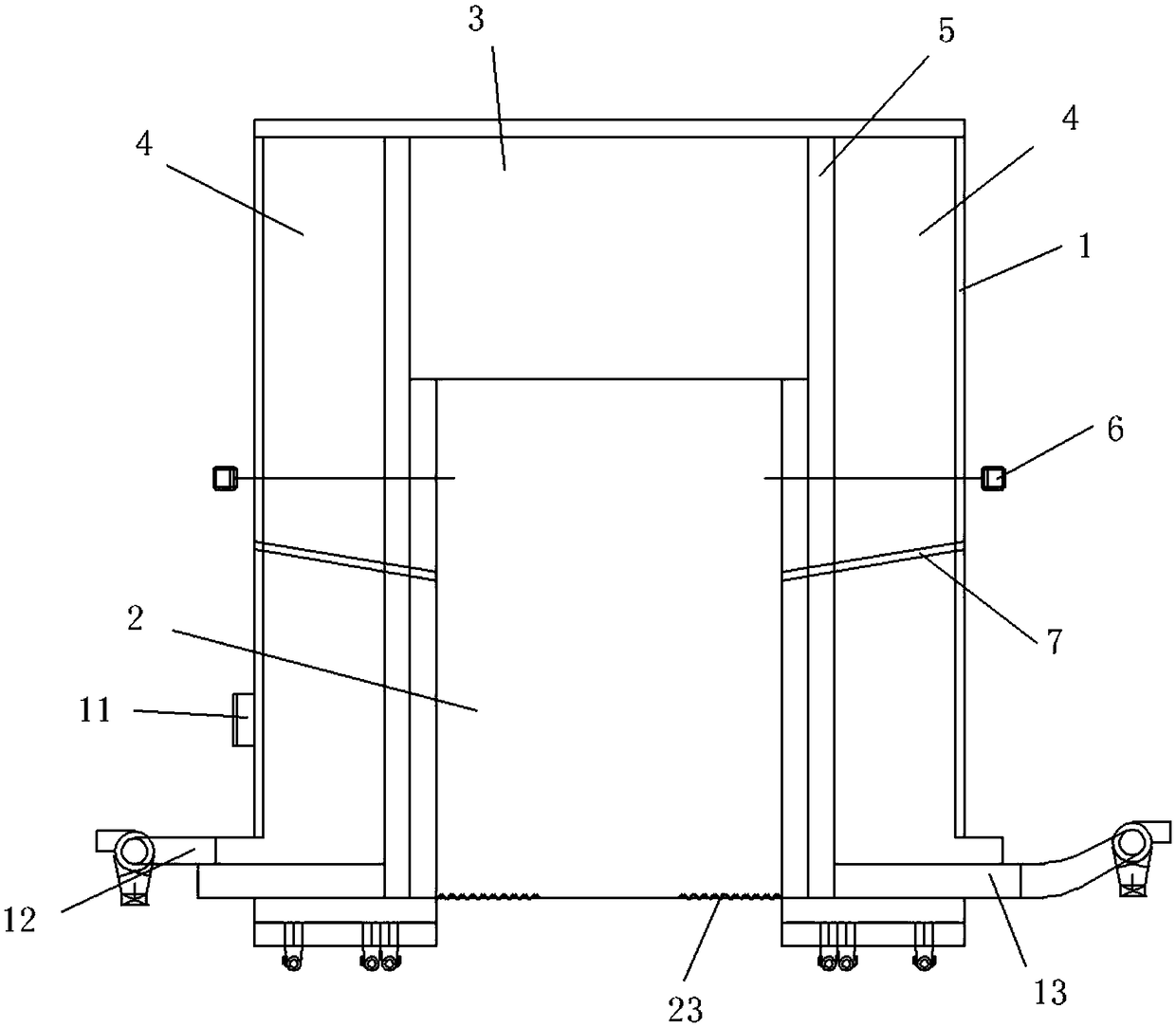

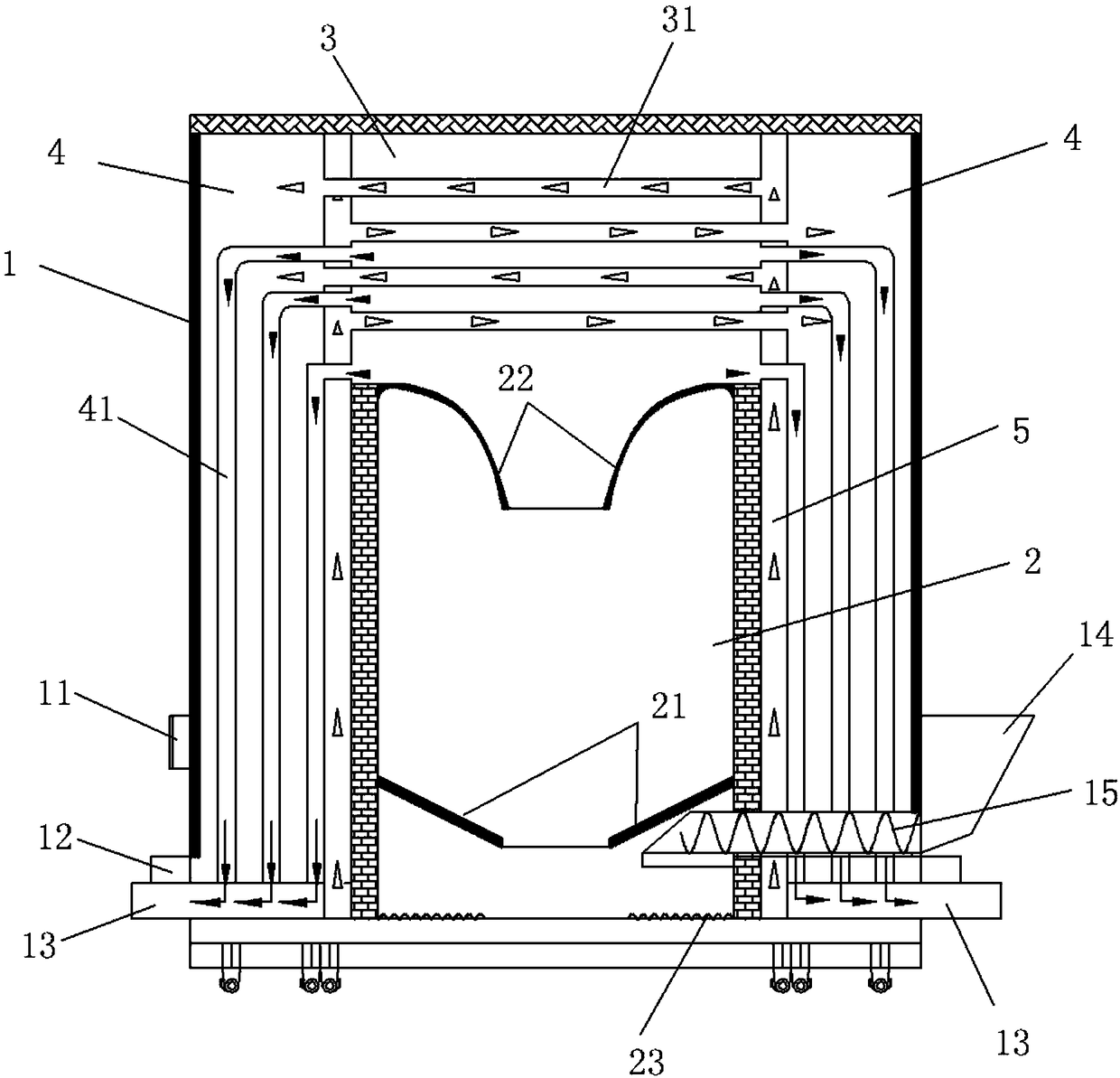

[0018] A double heat exchange chamber grain drying hot air stove, comprising a furnace body 1 and a combustion chamber 2, characterized in that: the combustion chamber 2 is arranged inside the furnace body 1, and a preheating jacket 5 is arranged on the outside of the combustion chamber 2 to preheat The jacket 5 is arranged close to the side wall of the combustion chamber 2, and extends from the bottom of the furnace body 1 to the top of the furnace body 1. The height of the preheating jacket 5 is greater than that of the combustion chamber 2, and a preheating clamp The first heat exchange chamber 3 formed by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com