Assembled monolithic underground pipe gallery, drainage ditch or flood ditch

A technology of comprehensive pipe gallery and drainage ditch, which is applied in water conservancy projects, underwater structures, artificial islands, etc., can solve the problems of large cross-sectional size of prefabricated components, difficult waterproofing of joints, low production efficiency of factories, etc., and achieve hoisting The effects of small conditions, reduced labor and formwork consumption, and high difficulty in vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

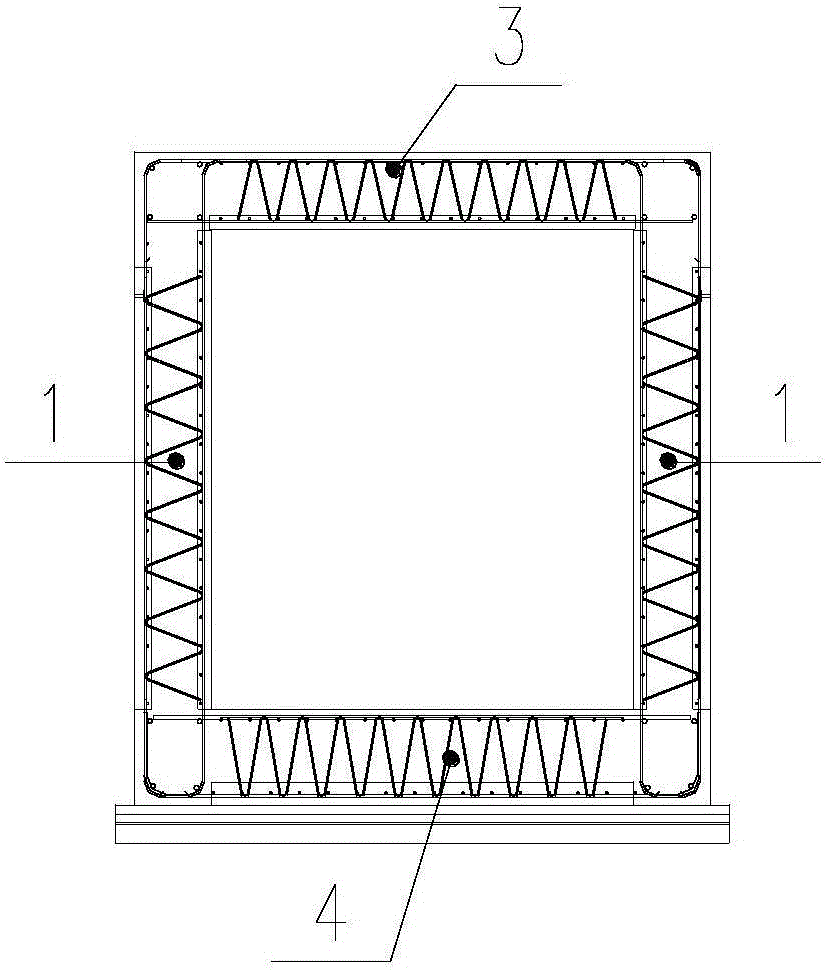

[0037] Such as figure 1 The shown single-chamber assembled integrated integrated pipe gallery, drainage ditch or flood ditch includes laminated exterior wall panels 1, laminated roof panels 3, laminated bottom panels 4 or cast-in-place bottom panels, and composite roof panels 3 include roof prefabricated layers and The top plate cast-in-place layer, the laminated bottom plate 4 includes the bottom plate prefabricated layer and the bottom plate cast-in-place layer, the cast-in-place bottom plate includes the bottom plate cast-in-place layer, and the laminated exterior wall panel 1 includes the exterior wall panel prefabricated layer and the exterior wall panel cast-in-place layer. The laminated base plate 4 or the cast-in-place base plate is set on the foundation cushion or the waterproof layer (or waterproof protection layer), and the prefabricated parts of all laminated components (the laminated base plate, the laminated top plate and the laminated outer wall panel) are equipp...

Embodiment 2

[0045] This embodiment is a two-cabin or three-cabin assembly integrated integrated pipe gallery, drainage ditch or flood ditch, see figure 2 , 3 , the structure difference from embodiment 1 is that the laminated inner wall panel 2 is added, such as Figure 5 , 10 As shown in , 11, the laminated interior wall panel 2 includes the prefabricated interior wall panel and the cast-in-place interior wall panel, and the interior wall panel prefabricated layer consists of the outer prefabricated panel 8 of the interior wall panel, the inner prefabricated panel 9 of the interior wall panel and the truss The upper and lower chords of the truss bars 7 are respectively pre-embedded in the two-layer prefabricated slabs and replace the corresponding vertical steel bars, and the vertical steel bars protruding from the lower ends of the inner and outer two-layer prefabricated slabs are bent and overlapped with each other The resulting return bars are anchored in the cast-in-place layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com