530 MPa-grade thin galvanized band steel and production method thereof

A production method and 530mpa technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of extremely high requirements for rapid cooling capacity of galvanizing equipment, unfavorable wide-scale promotion and application, and difficult control. , to reduce the difficulty of production control, improve the quality of galvanized surface, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

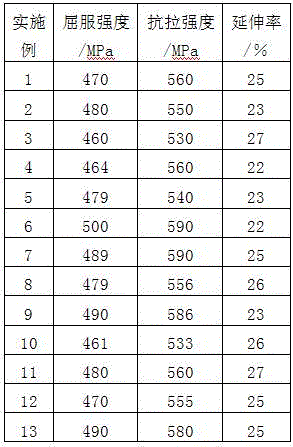

[0016] A 530MPa grade thin gauge galvanized steel strip and its production method. The mass percentage of the chemical composition of the galvanized steel strip is: C: 0.08%~0.12%, preferably C: 0.08%~0.10%; Si: ≤0.06% Mn: 1.1%~1.5%; P: ≤0.016%, preferably P: ≤0.012%; S: ≤0.008%; Nb: 0.040%~0.055%; Als: 0.020%~0.045%; N: ≤0.007%, Preferably N: ≤0.005%; Ti: 0.015%~0.030%; Ca: 0.0015%~0.0045%; the balance is Fe;

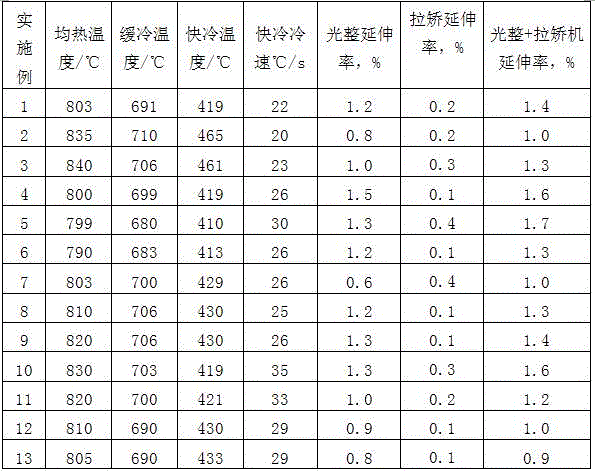

[0017] The production method includes smelting, hot rolling, continuous annealing before galvanizing and smoothing and straightening after galvanizing. In the smelting process, the converter and LF refining adopt low-nitrogen mode smelting, continuous casting protection casting control nitrogen increase, and LF refining calcium before treatment The acid-soluble aluminum content of molten steel is controlled within 0.025%~0.045%. After calcium treatment, the molten steel is protected by the LF refining furnace cover, and the bottom argon gas is used to blow the molten stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com