High modulus, ultrahigh strength TiB2 particle reinforced Al-Zn-Mg-CU composite material and preparation method thereof

A composite material and particle reinforcement technology, applied in the field of composite materials, can solve problems such as loss, alloy stress corrosion cracking, and difficulty in further upgrading, and achieve the effects of uniform distribution area, small size, optimized homogenization process and extrusion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

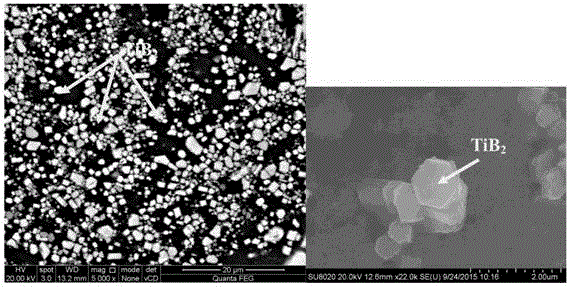

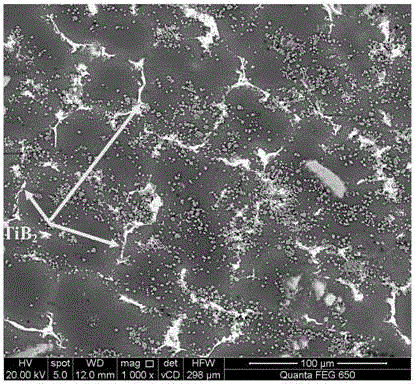

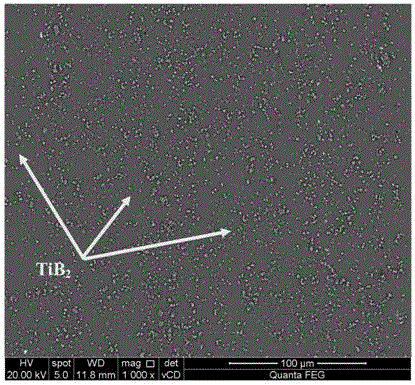

[0023] Preparation of TiB by two-step method 2 / Al-Zn-Mg-Cu composite material process is as follows:

[0024] (1) The configuration scheme of the composite material is: 9.96% TiB 2 , 10% Zn, 1.9% Mg, 1.7% Cu, 0.12% Zr, and the balance is Al. where Al-TiB 2 The master alloy consists of aluminum ingot, aluminum powder, titanium powder, TiO 2 、H 3 BO 3 Prepared, wherein the molar ratio of total Ti / B=1:4, Al powder, Ti powder and TiO 2 The mass ratio is 2:2:3, and the Al-TiB2 master alloy with high mass fraction and average size below 1 μm is prepared by melt self-propagating direct synthesis method.

[0025] (2) Preparation is carried out, wherein the total Ti / B=1:4. The Al-Zn-Mg-Cu matrix alloy is prepared from pure aluminum ingots, pure zinc ingots, pure magnesium ingots, Al-50% Cu and Al-4% Zr master alloys.

[0026] (3) Preparation of Al-TiB 2 Master alloy, weigh TiO as required 2 、H 3 BO 3 , mix the two powders evenly, and heat at 200 °C for two hours to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com