Preparation method of copper metal organic frameworks / polyvinyl alcohol nanocomposite films

A technology of polyvinyl alcohol and organic framework, which is applied in the field of preparation of copper metal organic framework (Cu32)/polyvinyl alcohol nanocomposite film, can solve problems such as not being able to meet the requirements of use, and achieve the effect of good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

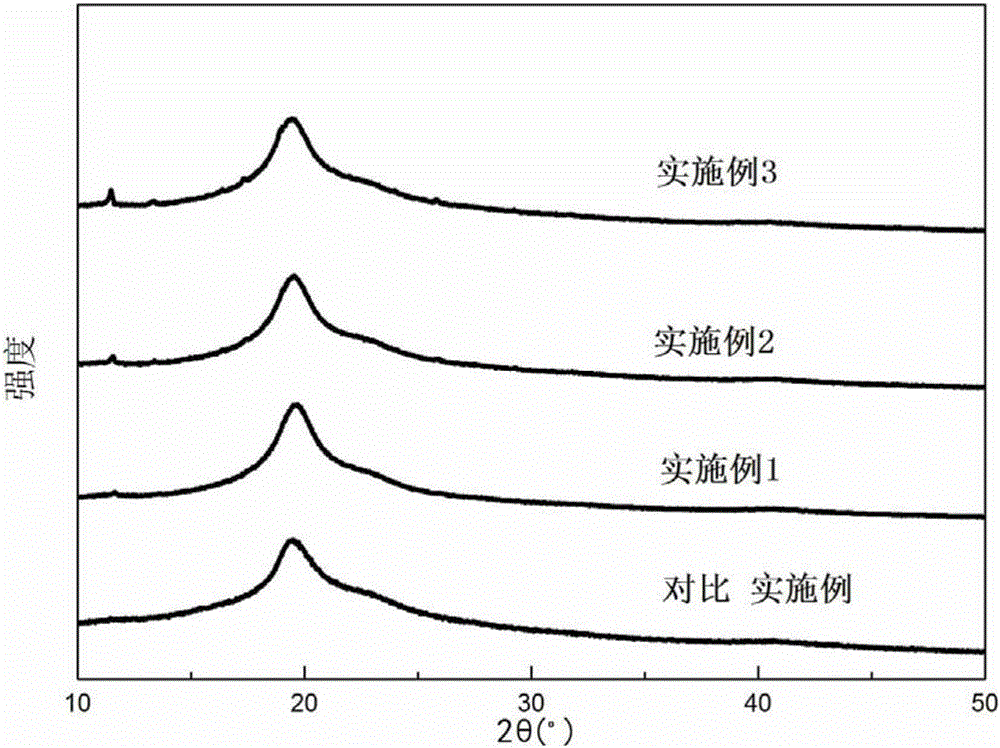

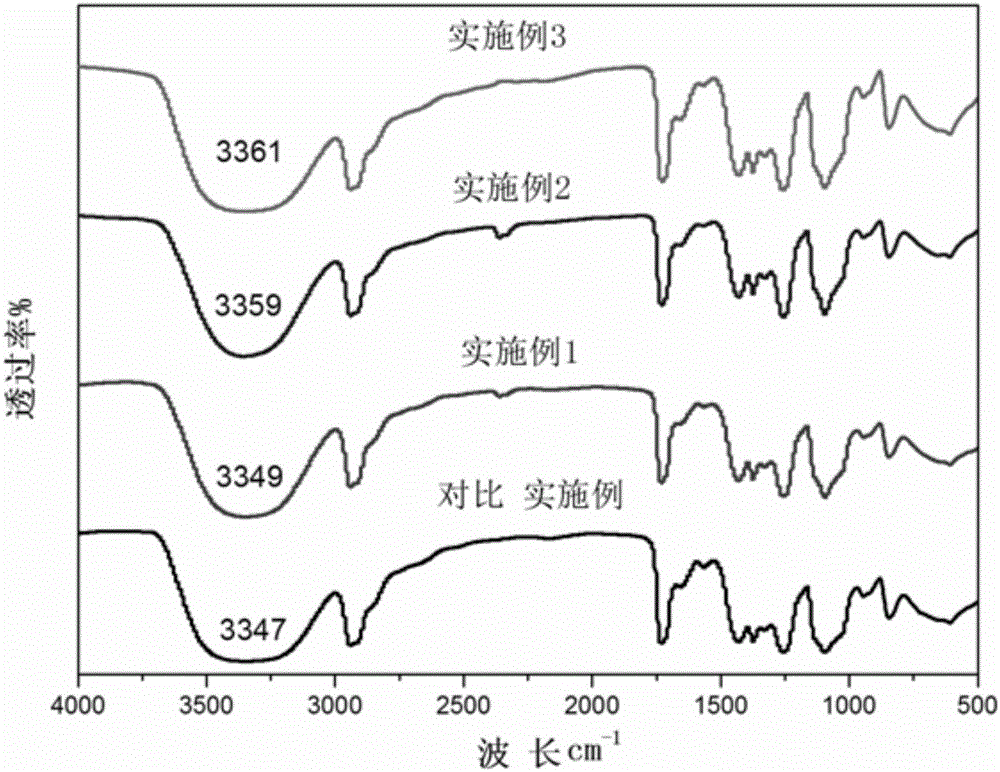

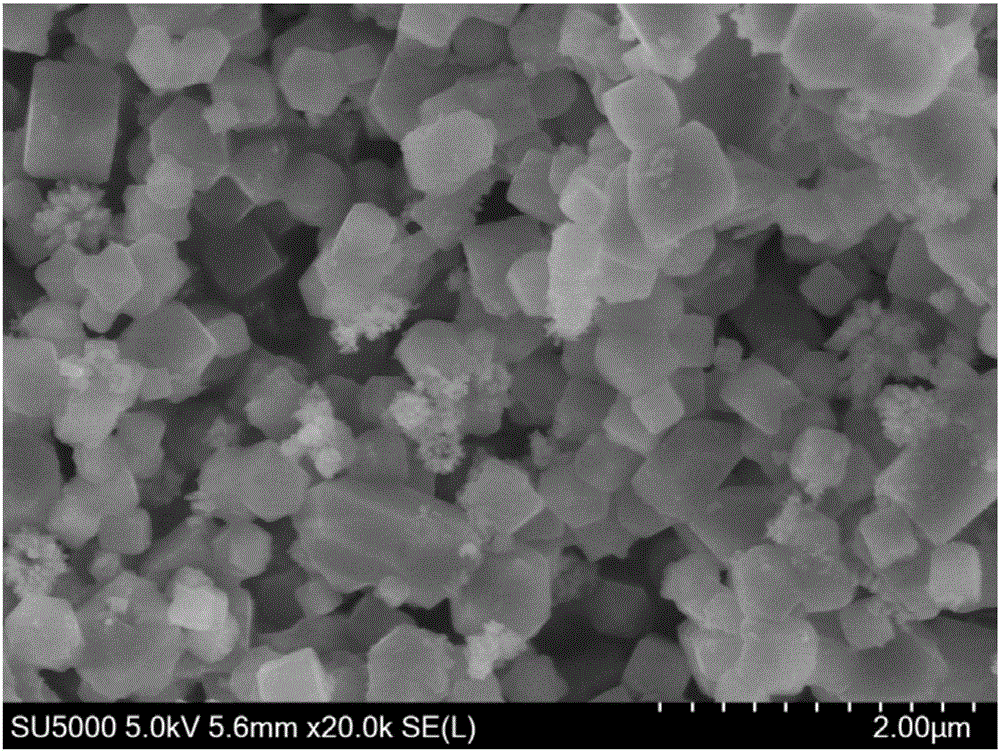

[0019] Embodiment 1: mass percent concentration is 0.05% Cu 3 (BTC) 2 / Preparation of polyvinyl alcohol film

[0020] (1) Weigh 10g of polyvinyl alcohol particles into 100mL of deionized water, heat to 60°C, and stir for 1 hour to obtain a polyvinyl alcohol solution with a mass percentage concentration of 10% for use.

[0021] (2) Add 1.5 mL of Cu(NO 3 ) 2 The solution was mixed with 1 mL of triethylamine salt solution of trimesic acid with a concentration of 0.1 mol / L.

[0022] (3) Mix ethanol and deionized water at a volume ratio of 1:1.

[0023] (4) Evenly mix the solution obtained in step (2) with 50 mL of ethanol aqueous solution obtained in step (3), stir and react at room temperature at 1000 rpm for 1 hour, and centrifuge the obtained solution after the reaction is completed. The centrifugation time is 10 minutes, and the centrifugation speed is 1000rpm, pour off the original solution, remove the solid in the lower layer, add absolute ethanol and deionized water t...

Embodiment 2

[0025] Embodiment 2: mass percent concentration is 0.1% Cu 3 (BTC) 2 / Preparation of polyvinyl alcohol film

[0026] (1) Weigh 10g of polyvinyl alcohol particles into 100mL of deionized water, heat to 60°C, and stir for 1 hour to obtain a polyvinyl alcohol solution with a mass percentage concentration of 10% for use.

[0027] (2) Add 1.5 mL of Cu(NO 3 ) 2 The solution was mixed with 1 mL of triethylamine salt solution of trimesic acid with a concentration of 0.1 mol / L.

[0028] (3) Mix ethanol and deionized water at a volume ratio of 1:1.

[0029] (4) Uniformly mix the solution obtained in step (2) with 50 mL of ethanol aqueous solution obtained in step (3), stir and react at room temperature at 1000 rpm for 1 hour, and centrifuge the obtained solution after the reaction. The centrifugation time is 12 minutes, and the centrifugation speed is 1500rpm, pour off the original solution, remove the solid in the lower layer, add absolute ethanol and deionized water to wash by c...

Embodiment 3

[0031] Embodiment 3: mass percentage concentration is the Cu of 0.2% 3 (BTC) 2 / Preparation of polyvinyl alcohol film

[0032](1) Weigh 10g of polyvinyl alcohol particles into 100mL of deionized water, heat to 60°C, and stir for 1 hour to obtain a polyvinyl alcohol solution with a mass percentage concentration of 10% for use.

[0033] (2) Add 1.5 mL of Cu(NO 3 ) 2 The solution was mixed with 1 mL of triethylamine salt solution of trimesic acid with a concentration of 0.1 mol / L.

[0034] (3) Mix ethanol and deionized water at a volume ratio of 1:1.

[0035] (4) Uniformly mix the solution obtained in step (2) with 50 mL of the ethanol aqueous solution obtained in step (3), stir and react at room temperature at 1000 rpm for 2 hours, and centrifuge the obtained solution after the reaction. The centrifugation time is 15 minutes, and the centrifugation speed is 2000rpm, pour off the original solution, remove the solid in the lower layer, add absolute ethanol and deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com