A method for the rapid synthesis of hierarchically porous hkust-1 materials by a dual-functional template method

A HKUST-1, hierarchical pore technology, applied in the field of rapid preparation of hierarchical porous metal-organic framework materials, achieves the effects of energy saving, stable structure, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1.093g Cu(NO 3 ) 2 ·3H 2 O was dissolved in 15ml deionized water, 0.525g trimesic acid (H 3 BTC) was dissolved in 15ml methanol and stirred for 20 minutes respectively; Cu(NO 3 ) 2 ·3H 2 O aqueous solution was added to the methanol solution of trimesic acid to obtain a mixed solution, and the stirring was continued for 5 minutes; 1.12 g template agent N, N, N, N-tetramethylhexamethylenediamine (purchased from Bailingwei, the same below) was added to the mixed solution , and continued to stir for 30 s; the solution was filtered with suction, and the obtained solid was dried in a vacuum oven at 120°C for 12 hours to prepare a multi-level porous HKUST-1 material, labeled as sample A1.

Embodiment 2

[0031] 1.093g Cu(NO 3 ) 2 ·3H 2 O was dissolved in 15ml deionized water, 0.576g trimesic acid (H 3 BTC) was dissolved in 15ml methanol and stirred for 15 minutes respectively; Cu(NO 3 ) 2 ·3H 2 O aqueous solution was added to the methanol solution of trimesic acid to obtain a mixed solution, and the stirring was continued for 10 minutes; 1.20 g template agent N, N, N, N-tetramethylhexamethylenediamine was added to the mixed solution, and the stirring was continued for 30 s; the solution After suction filtration, the obtained solid was dried in a vacuum oven at 120° C. for 16 hours to prepare a multi-level porous HKUST-1 material, labeled as sample A2.

Embodiment 3

[0033] 1.093g Cu(NO 3 ) 2 ·3H 2O was dissolved in 15ml deionized water, 0.479g trimesic acid (H 3 BTC) was dissolved in 15ml methanol and stirred for 18 minutes respectively; Cu(NO 3 ) 2 ·3H 2 O aqueous solution was added to the methanol solution of trimesic acid to obtain a mixed solution, and the stirring was continued for 8 minutes; 1.16 g of template agent N, N, N, N-tetramethylhexamethylenediamine was added to the mixed solution, and the stirring was continued for 30 s; After suction filtration, the obtained solid was dried in a vacuum oven at 120° C. for 14 hours to prepare a multi-level porous HKUST-1 material, labeled as sample A3. .

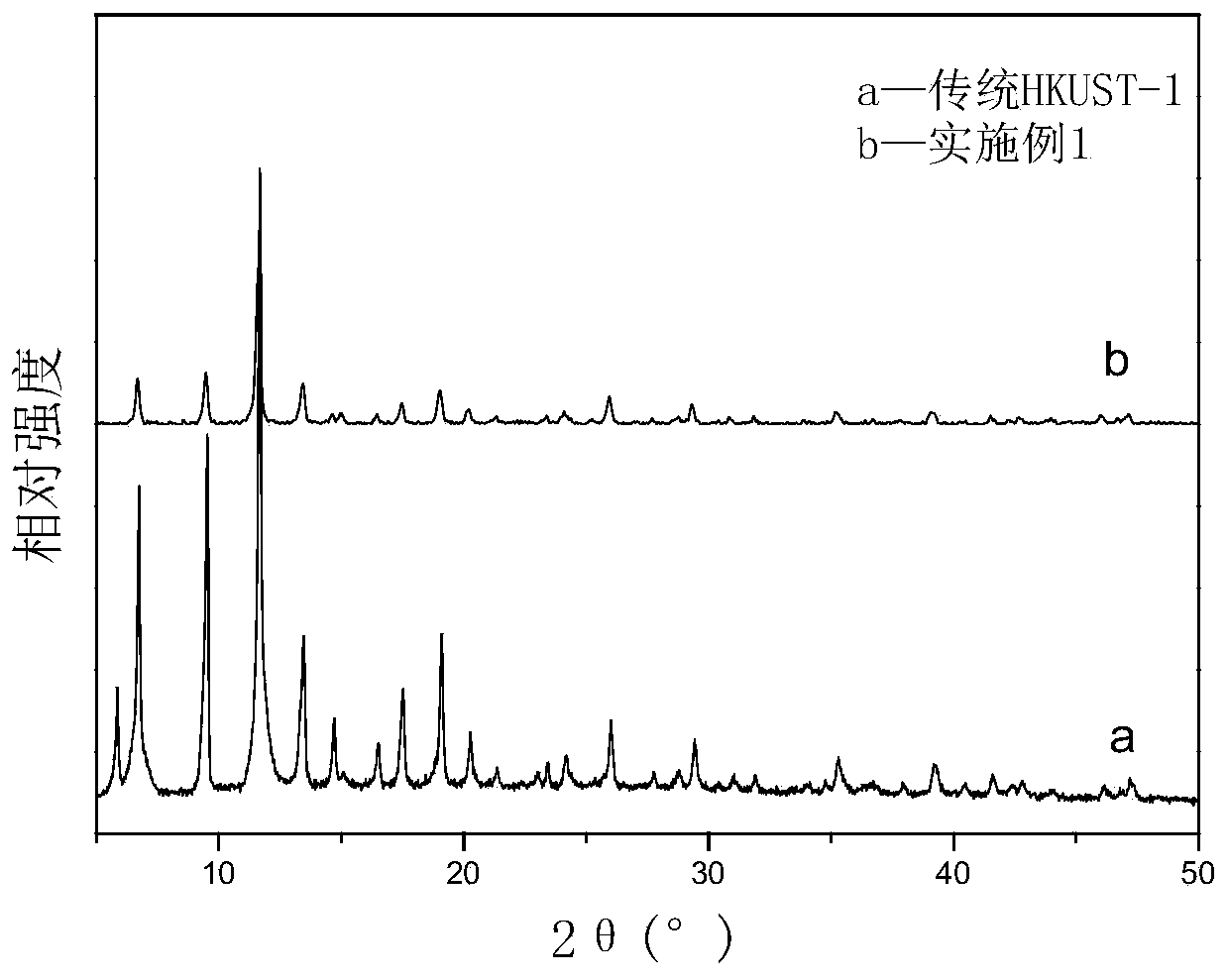

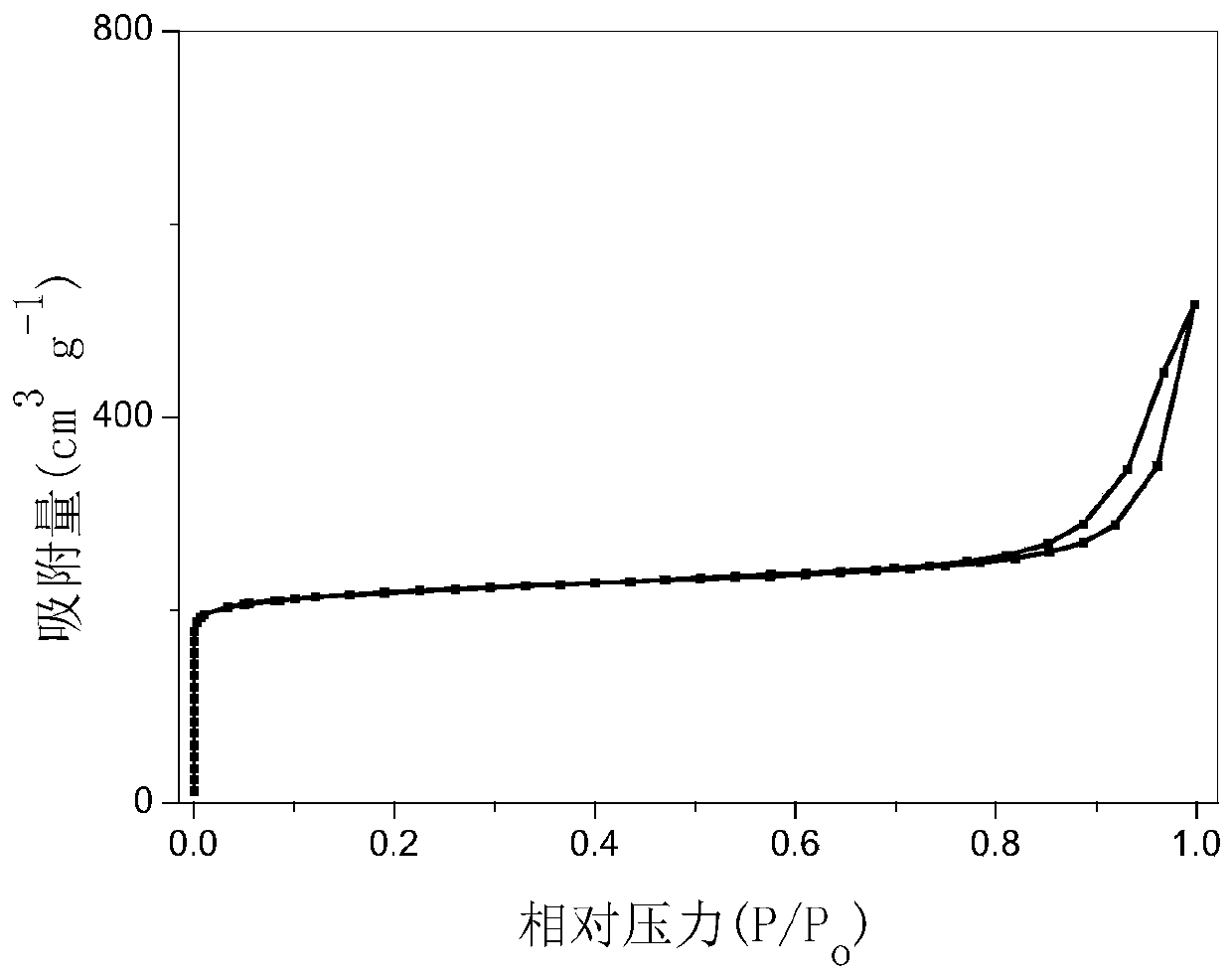

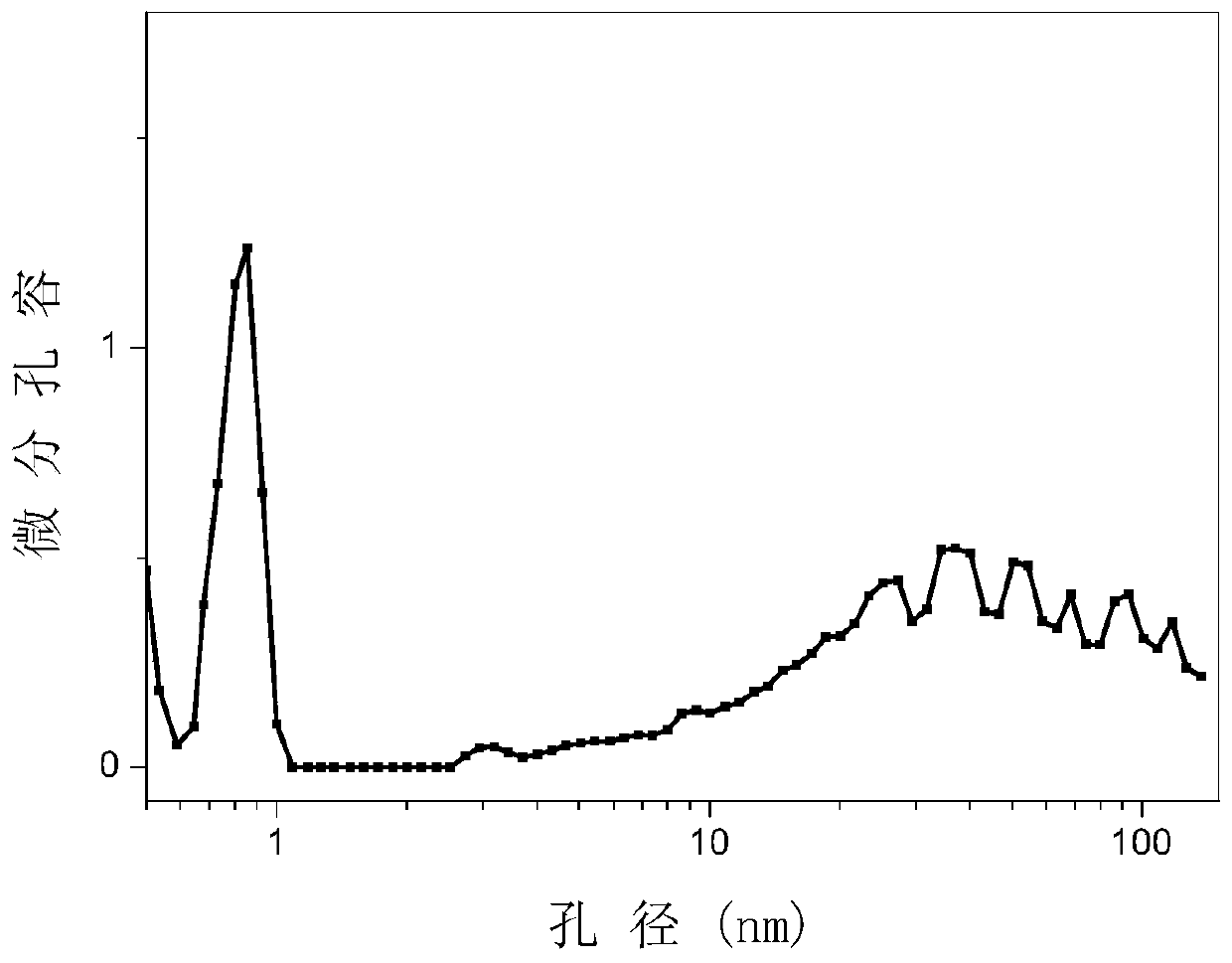

[0034] Taking the effect of the hierarchically porous HKUST-1 material prepared in Example 1 as a representative to analyze the effect of the present invention, the analytical results of the hierarchically porous HKUST-1 material prepared in other examples are basically the same as those in Example 1, so they are not one by one. s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com