Plant-growing ecological concrete

A technology of ecological concrete and recycled concrete, applied in the field of ecological concrete, can solve the problems of mechanical strength damage, poor durability, affecting mechanical strength, etc., and achieve long-lasting stability and durability, long compressive duration, and good compressive effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

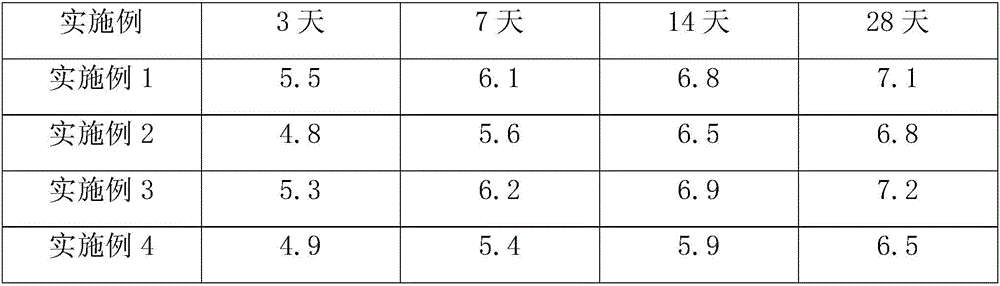

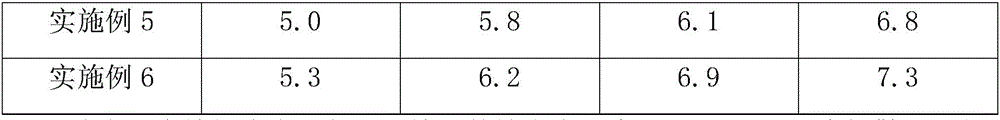

Examples

Embodiment 1

[0013] Planting ecological concrete of the present embodiment, the raw material comprises the following components by weight: 400 parts of recycled concrete aggregate, 100 parts of ordinary portland cement, 20 parts of sodium dodecylbenzene sulfate, 10 parts of sodium nitrite antifreeze, 5 parts of vinyl acetate-vinyl chloride copolymer, 0.03 parts of medium polycarboxylate superplasticizer, 5 parts of low alkali value synthetic calcium alkylbenzene sulfonate, 10 parts of oleic acid, 5 parts of methacrylic acid, 10 parts of water-absorbing resin, stabilized 3 parts of foaming agent, 60 parts of water;

[0014] In this embodiment, the water-absorbent resin is prepared by saponification with alkali after copolymerization of vinyl acetate and methyl acrylate;

[0015] In this embodiment, the foam stabilizer is a mixture of soybean dregs, higher carbon alcohol, sodium hydroxide, triethanolamine and water;

[0016] In this example, the recycled concrete aggregate is prepared in th...

Embodiment 2

[0018] Planting ecological concrete of the present embodiment, raw material comprises the following components by weight: 500 parts of recycled concrete aggregate, 120 parts of ordinary Portland cement, 30 parts of sodium dodecylbenzene sulfate, 20 parts of sodium nitrite antifreeze, 10 parts of vinyl acetate-vinyl chloride copolymer, 0.08 parts of medium polycarboxylate superplasticizer, 15 parts of low alkali value synthetic calcium alkylbenzene sulfonate, 20 parts of oleic acid, 15 parts of methacrylic acid, 20 parts of water-absorbing resin, stabilizer Foam agent 10 parts, water 80 parts;

[0019] In this embodiment, the water-absorbent resin is prepared by saponification with alkali after copolymerization of vinyl acetate and methyl acrylate;

[0020] In this embodiment, the foam stabilizer is a mixture of soybean dregs, higher carbon alcohol, sodium hydroxide, triethanolamine and water;

[0021] In this example, the recycled concrete aggregate is prepared by crushing wa...

Embodiment 3

[0023] Planting ecological concrete of the present embodiment, raw material comprises the following components by weight: 450 parts of recycled concrete aggregates, 110 parts of ordinary Portland cement, 25 parts of sodium dodecylbenzene sulfate, 15 parts of sodium nitrite antifreeze, 7 parts of vinyl acetate-vinyl chloride copolymer, 0.06 parts of medium polycarboxylate superplasticizer, 10 parts of low alkali value synthetic calcium alkylbenzene sulfonate, 15 parts of oleic acid, 10 parts of methacrylic acid, 15 parts of water-absorbing resin, stabilizer Foaming agent 6 parts, water 70 parts;

[0024] In this embodiment, the water-absorbent resin is prepared by saponification with alkali after copolymerization of vinyl acetate and methyl acrylate;

[0025] In this embodiment, the foam stabilizer is a mixture of soybean dregs, higher carbon alcohol, sodium hydroxide, triethanolamine and water;

[0026] In this example, the recycled concrete aggregate is prepared in the follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com