Nitrogen and phosphorus removal composite agent and preparation method thereof

A comprehensive agent, denitrification technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc. High cost and other problems, to achieve the effect of superior effect, simple preparation and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A comprehensive agent for phosphorus and nitrogen removal, formulated according to the following mass percentages:

[0041] 20kg of metal compounds, including 6kg of aluminum sulfate, 10kg of ferrous sulfate, and 4kg of lanthanum oxide;

[0042] 10kg of natural mineral powder, including 5kg of bentonite, 3kg of attapulgite, and 2kg of diatomite;

[0043] 10kg of flocculant, including 6kg of polyferrosilicate flocculant and 4kg of polyacrylamide;

[0044] Coagulant aid 5kg, including calcium oxide 2kg, calcium hydroxide 3kg;

[0045] Strong oxidizing agent 10kg, bromochlorohydantoin 7kg, potassium hypochlorite 3kg.

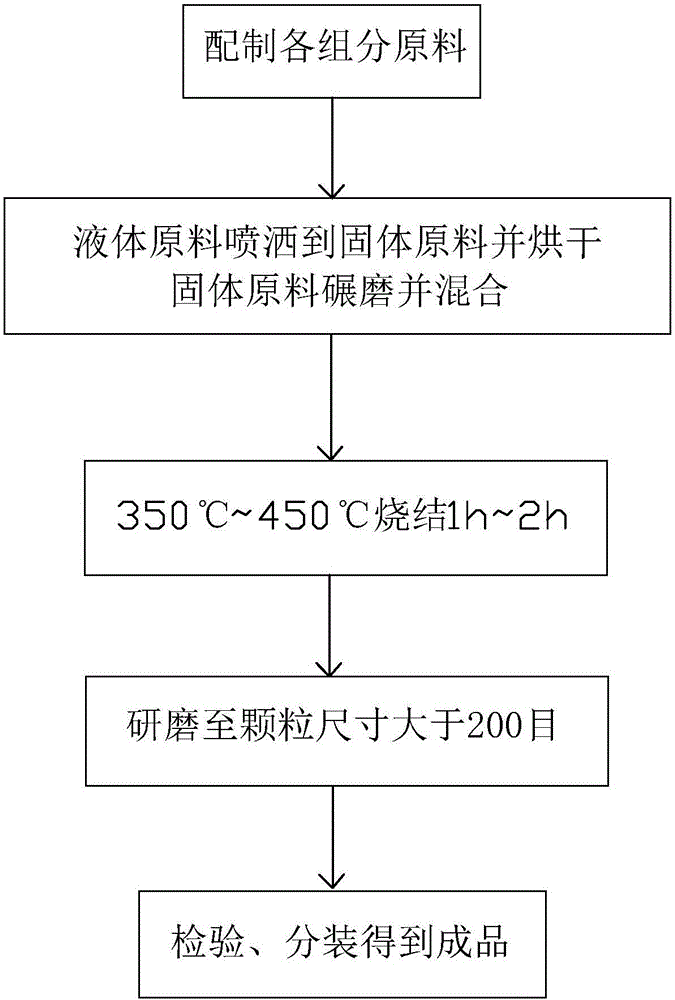

[0046] as per figure 1 The process shown in the preparation of comprehensive phosphorus and nitrogen removal agent, the specific steps are:

[0047] a. Prepare the raw materials of each component of the phosphorus and nitrogen removal comprehensive agent according to the above-mentioned mass percentage;

[0048] b. Spray the liquid raw material on the sol...

Embodiment 2~ Embodiment 5

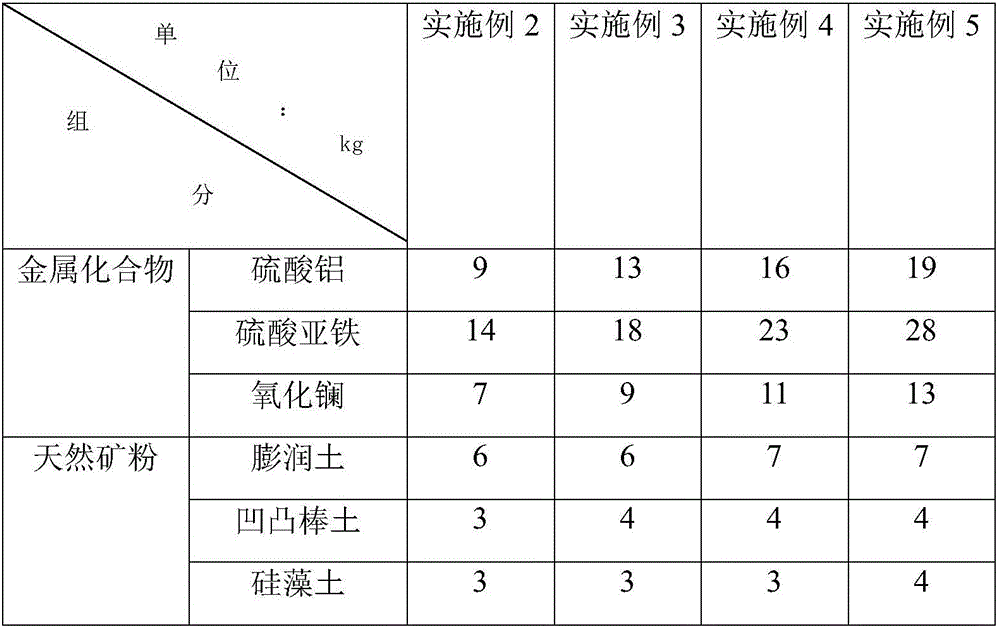

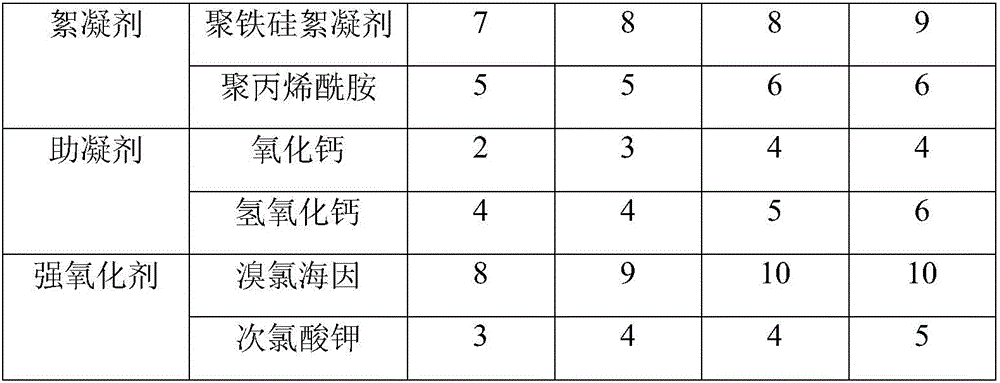

[0053] The difference between Example 2-Example 5 and Example 1 is that the distribution ratio of each component is different, see Table 1 for details.

[0054] The composition distribution ratio of table 1 embodiment 2~embodiment 5

[0055]

[0056]

[0057] Taking the production sewage of China Salt Anhui Hongsifang Co., Ltd. as a sample, the nitrogen and phosphorus removal agent produced by Foshan Demiao Environmental Protection Technology Co., Ltd. with the model DM was selected as a representative of ordinary phosphorus and nitrogen removal agents to discuss the comprehensive process of phosphorus and nitrogen removal. The phosphorus removal effect of the agent.

[0058] Take 3000mL of sewage water samples, test the phosphorus content and ammonia nitrogen content of sewage, and test the phosphorus and ammonia nitrogen removal. Determination of phosphorus - ammonium molybdate spectrophotometry, ammonia nitrogen cooking titration as standard. The total phosphorus co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com