Graphene-polymer micro-wire array, gas sensor, and preparation methods and application thereof

A gas sensor and graphene technology, applied in the direction of electric solid-state devices, semiconductor devices, instruments, etc., can solve the problems of cumbersome methods, difficult large-area preparation, poor sensitivity, etc., and achieve the effect of simple equipment, high detection sensitivity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

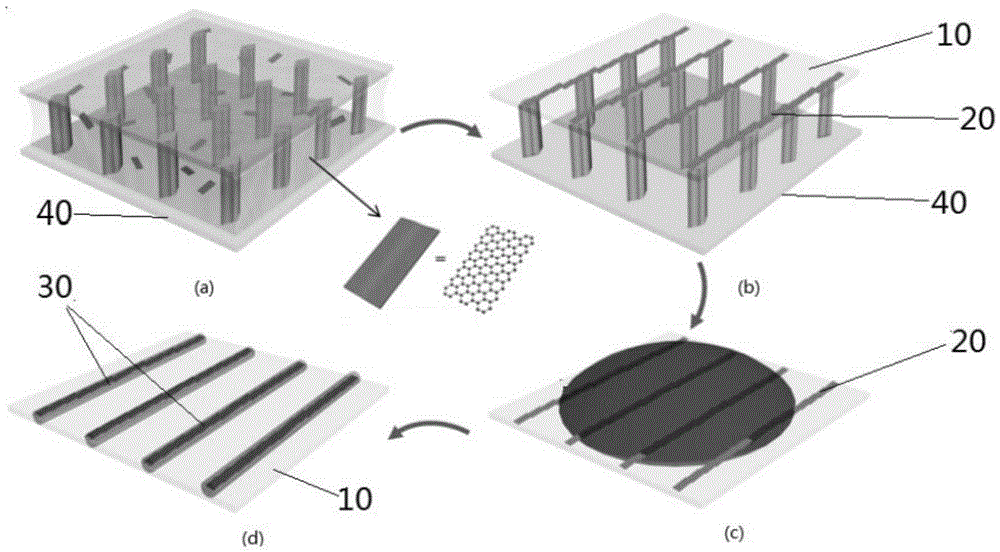

[0042] Such as figure 1 and figure 2 Shown, the present invention also provides a kind of preparation method of graphene-polymer microwire array gas sensor, adopts this method to prepare the graphene-polymer microwire of high sensitivity, high selectivity and performance stability simply and quickly Array gas sensors. It includes the following steps:

[0043] S1. Prepare graphene micro-wire array 20 by liquid bridge induction method, specifically including:

[0044] S11, setting the substrate 10, and ultrasonically dispersing the graphene in the first solvent to form a graphene dispersion, and then placing the graphene dispersion on the substrate 10;

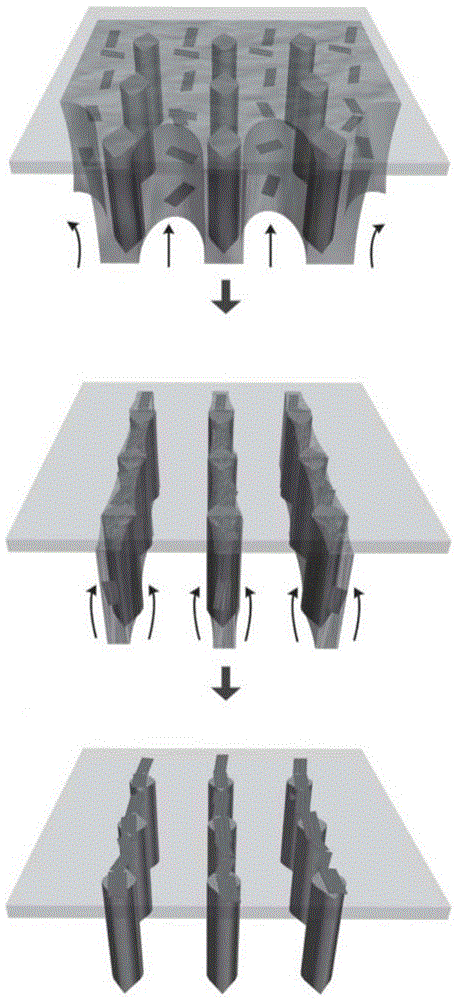

[0045] S12. Using the silicon pillars with micron array structure as the template 40, drop the graphene dispersion on the template 40 to form a sandwich structure. Wherein, the template 40 is a silicon pillar with a patterned micron array structure. For example, the template 40 can be obtained by photolithography.

[0046...

Embodiment 1

[0054] (1) Fabrication of large-area graphene microwire arrays by liquid bridge induction method

[0055] A silicon pillar with a pattern of a micron size is selected as a template, the size (width) of the silicon pillar is 2 μm, and the distance between the silicon pillars is 2 μm. Graphene is ultrasonically dispersed in water to form a graphene dispersion with a concentration of 800ppm, and the dispersion is added dropwise on the ITO glass substrate. Place the silicon pillar template on top to form a sandwich structure. After standing at room temperature for 24 hours, after the solvent in the graphene dispersion layer between the substrate and the template volatilized, the silicon pillar template was removed, and a large-area graphene micro-line array was formed on the substrate due to the liquid bridge-induced shrinkage. Used in the next step to prepare polymer-coated gas sensors. see details figure 1 Step (a) and step (b) in.

[0056] (2) Preparation of graphene-polyme...

Embodiment 2

[0062] (1) Fabrication of large-area graphene microwire arrays by liquid bridge induction method

[0063] Silicon pillars with micron-sized patterns are selected as the template, the size (width) of the silicon pillars is 3 μm, and the distance between the silicon pillars is 3 μm. Graphene is ultrasonically dispersed in water to form a graphene dispersion with a concentration of 1200ppm, and the dispersion is added dropwise on the silicon wafer substrate. Place the silicon pillar template on top to form a sandwich structure. After standing at room temperature for 24 hours, after the solvent in the graphene dispersion layer between the substrate and the template volatilized, the silicon pillar template was removed, and a graphene microwire array was formed on the substrate due to the liquid bridge-induced shrinkage, which is used for the following One-step fabrication of polymer-coated gas sensors. See the process for details figure 1 Step (a) and step (b) in.

[0064] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com