Composite paper and preparation method thereof and waterproof mailing bag

A composite paper and squaring technology, applied in chemical instruments and methods, postal envelopes, transportation and packaging, etc., can solve problems such as poor waterproof ability, low tensile strength, damaged objects, etc., to reduce weight and cost, and waterproof performance superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

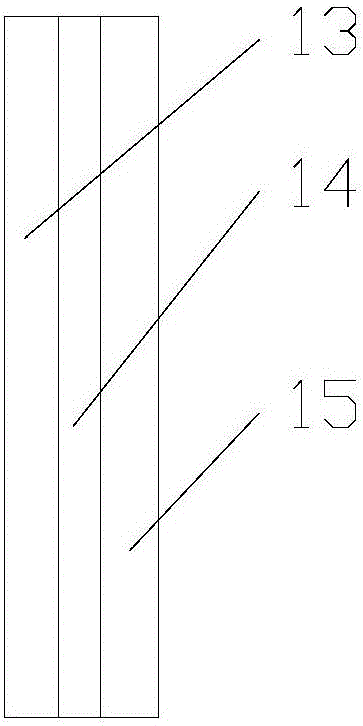

[0031] The present invention also provides the preparation method of above-mentioned composite paper, such as figure 2 As shown, the process steps are as follows:

[0032] S1. Add PP and PE into the blender according to the mass ratio of 0.5-2:1-3, and carry out the mixing process to obtain the mixed mixing material.

[0033] The specific operation is: according to the mass ratio of 0.5~2:1~3, add the PP color masterbatch with a diameter of 3 mm and the PE color masterbatch with a diameter of 3 mm into the hopper of the mixer, and put them under normal temperature. , according to the rotation speed of 100-140 rpm, the mixing material is stirred for 10-20 minutes, and the mixing material is fully mixed so that the mixing is uniform, and the mixed mixing material is obtained and set aside.

[0034] When mixing materials, if the water or humidity of the color masterbatch material is high, increase the mixing time accordingly to ensure that the mixing material is dry; the mixing...

Embodiment 1

[0054] S1. According to the mass ratio of 1:2, weigh 50 kg of PP masterbatch with a diameter of 3 mm, weigh 100 kg of PE masterbatch with a diameter of 3 mm, and add PP and PE masterbatch together In the hopper of the mixing material mixer, at room temperature, according to the rotation speed of 120 rpm, the mixing material is stirred for 15 minutes, and the mixing material is fully mixed, so that the PP and PE two kinds of color masterbatch materials are evenly mixed, and the mixed mixing material is obtained.

[0055] S2. Send 50 kg of PP color masterbatch to the hopper of a horizontal extrusion molding machine, extrude at 200°C, and perform parallel stretching at a stretching rate of 200 m / min, and then cool at room temperature to obtain 50 grams per square meter of stretch film, and finally the stretch film is rolled into a cylinder.

[0056] S3. Send the stretched film cylinder into the shredding equipment, spread it out and convey it, and then use the cutter set on the s...

Embodiment 2

[0062] S1. According to the mass ratio of 2:3, weigh 40 kg of PP masterbatch with a diameter of 3 mm, weigh 60 kg of PE masterbatch with a diameter of 3 mm, and add PP and PE masterbatch together In the hopper of the mixing material mixer, at room temperature, according to the rotation speed of 100 rpm, the mixing material is stirred for 10 minutes, and the mixing material is fully mixed, so that the two kinds of masterbatches of PP and PE are evenly mixed, and the mixed material is obtained.

[0063] S2. Send 75 kg of PP color masterbatch and 25 kg of red toning pink masterbatch to the hopper of the horizontal extrusion molding machine, and after fully mixing in the hopper, extrude at 230°C and 300 meters Parallel stretching was carried out at a stretching rate of 1 / min, followed by cooling to obtain a stretched film of 70 g / m2, and finally the stretched film was rolled into a cylinder.

[0064] S3. Send the stretched film cylinder into the shredding equipment, spread it out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com