High-hardness waterproof composite fabric

A composite cloth, high hardness technology, applied in the field of composite cloth, can solve problems such as unusable, composite cloth does not have waterproof performance, and achieve the effects of good thermal insulation performance, excellent waterproof performance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

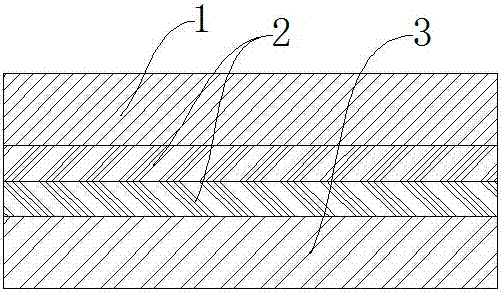

[0010] like figure 1 As shown, a high-hardness waterproof composite cloth described in this embodiment includes a surface layer 1 and a bottom layer 3, and two intermediate layers 2 are respectively arranged between the surface layer 1 and the bottom layer 3. The surface layer 1 It is a cotton cloth woven from cotton threads, the bottom layer 3 is a polyester cloth woven from polyester yarns, the two intermediate layers 2 are mesh cloths woven from polyethylene resin layers and carbon fiber yarns respectively, the surface layer 1, the bottom layer 3 and the The middle layers 2 are formed by compounding with glue. The carbon fiber yarn woven grid cloth is used as the middle layer 2 and the surface layer 1 is bonded, and the polyethylene resin layer is used as the middle layer 2 and the bottom layer 3 is bonded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com