Mechanical hand capable of switching rigidity and flexibility

A manipulator, rigid technology, applied in the field of manipulators, can solve the problems of grasping failure, manipulator deformation, objects falling off, etc., to achieve the effect of expanding the scope and field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

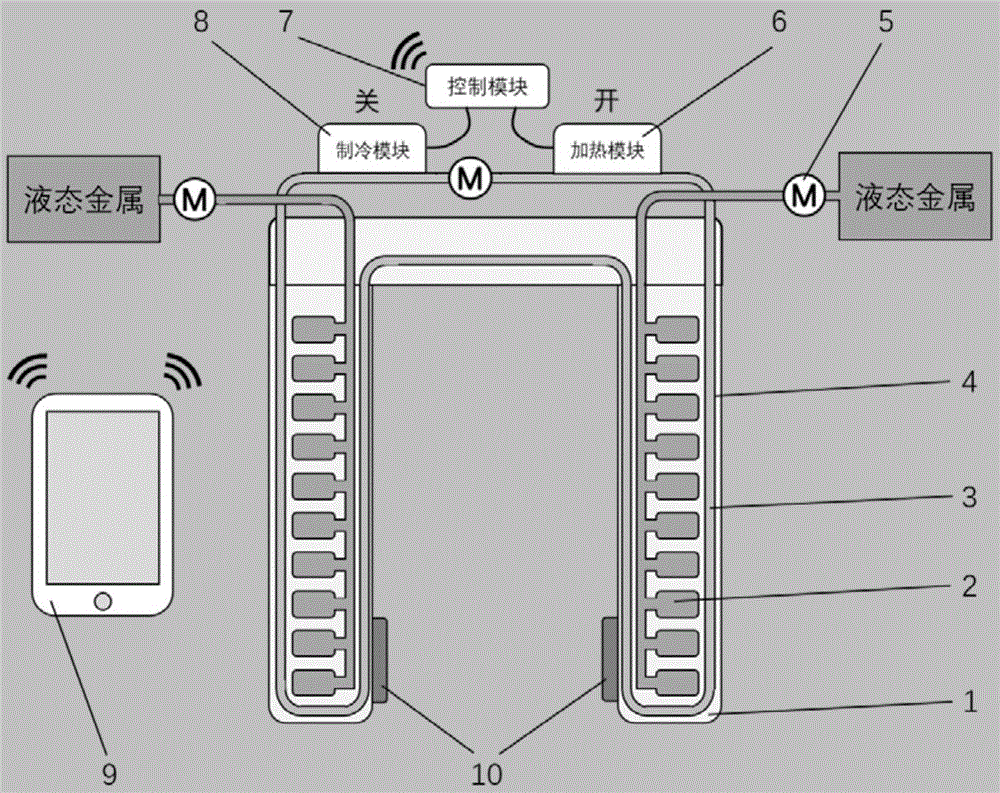

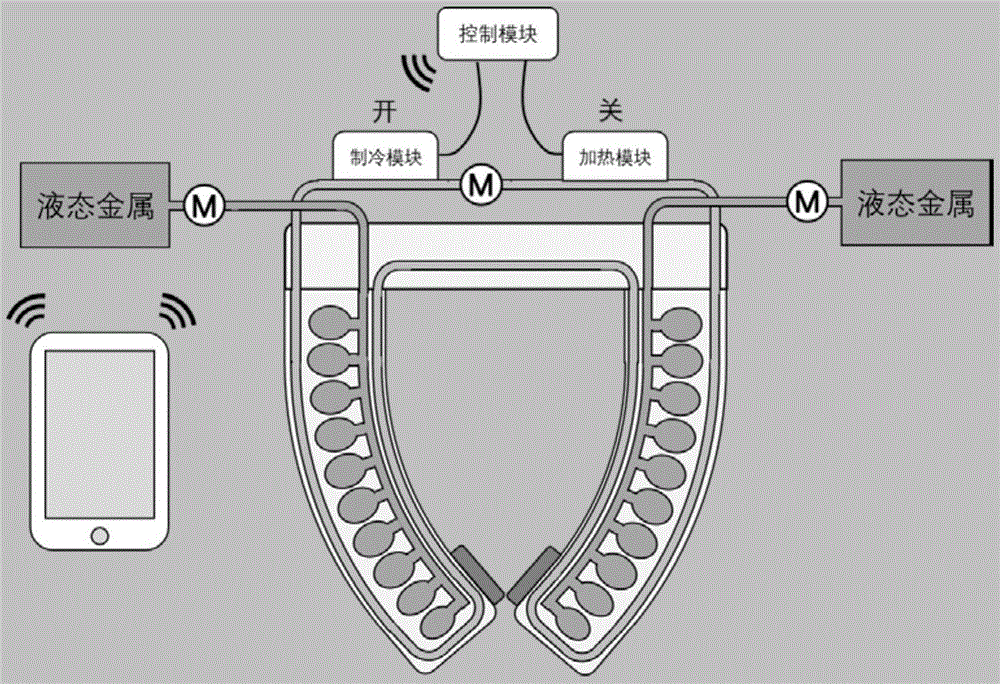

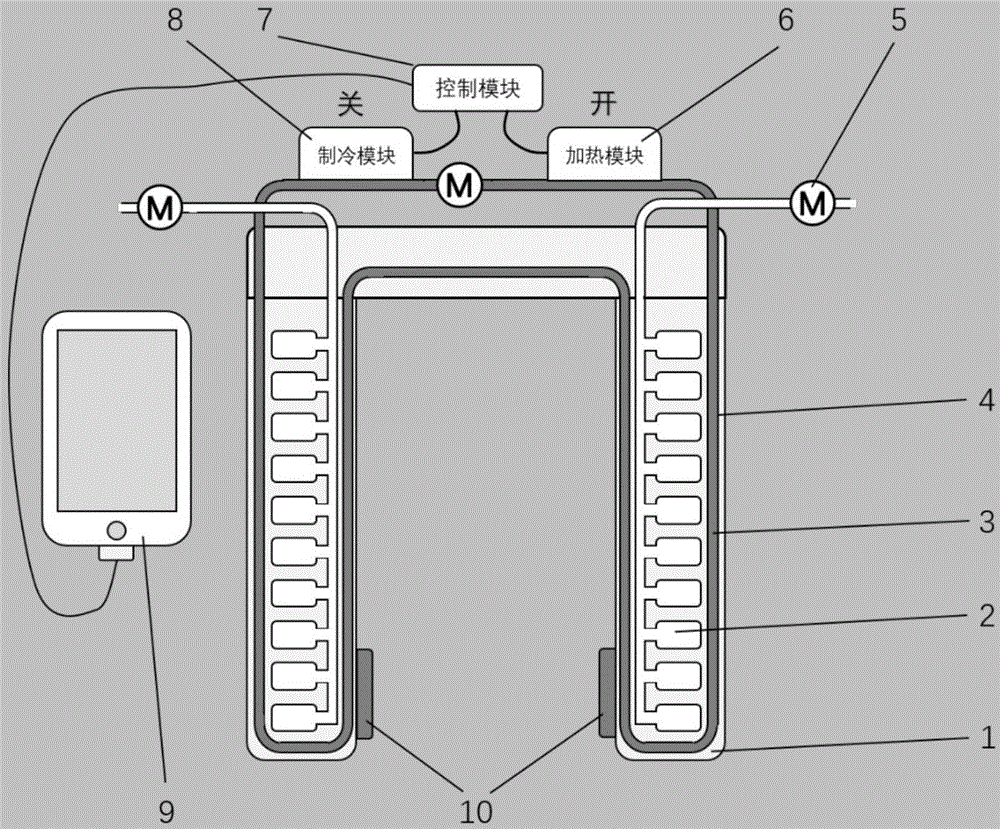

[0025] figure 1 and figure 2 It is a schematic diagram of the flexible variable manipulator proposed by the present invention, and the driving material is liquid metal, which is also an embodiment of the present invention.

[0026] figure 1 It is a diagram illustrating the interface of the manipulator in the unfolded state. In this embodiment, the manipulator has left and right fingers. The elastic polymer manipulator 1 is made of silicone material. The elastic polymer manipulator 1 has a liquid metal filling material 2 and a temperature control fluid 3 inside, and the temperature control fluid 3 and the liquid metal filling material 2 flow in the fluid pipeline 4 . Specifically in this embodiment, the temperature control fluid 3 circulates through the fluid pipeline 4, and the liquid metal filling material 2 is connected to the external liquid metal storage tank through the fluid pipeline 4, and can enter the elastic polymer manipulator 1 under the action of the fluid pum...

Embodiment 2

[0029] Such as image 3 As shown, the structure and modules of the elastic polymer manipulator 1 are the same as those in Embodiment 1, except that the liquid metal filling material 2 circulates in the pipeline. The manipulator is connected to the external atmosphere through the fluid pump 5, and by pumping gas into the cavity inside the manipulator, the cavity is expanded to realize the grasping action of the manipulator (such as Figure 4 shown). The data processing module 9 is connected with the control module 7 and the sensor module 10 by wire. In the initial state, the heating module 6 is in the open state and the refrigeration module 8 is in the closed state. With the transfer of heat in the liquid metal filling material 2, the entire liquid metal filling material 2 is in a liquid state. At this time, the fluid pump 5 starts to work, and the air is pumped into the cavity inside the elastic polymer manipulator 1 to make it produce a grasping action, such as Figure 4As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com