Radial cam loading and low-cycle fatigue splitting equipment for subdivision-type connecting rod fracture splitting

A technology of radial cam and low cycle fatigue, applied in the field of split connecting rod cracking processing for internal combustion engines, which can solve the problems of high master cylinder pressure requirements, fast cracking of connecting rods, and narrow application range, so as to improve cracking efficiency , good section quality and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

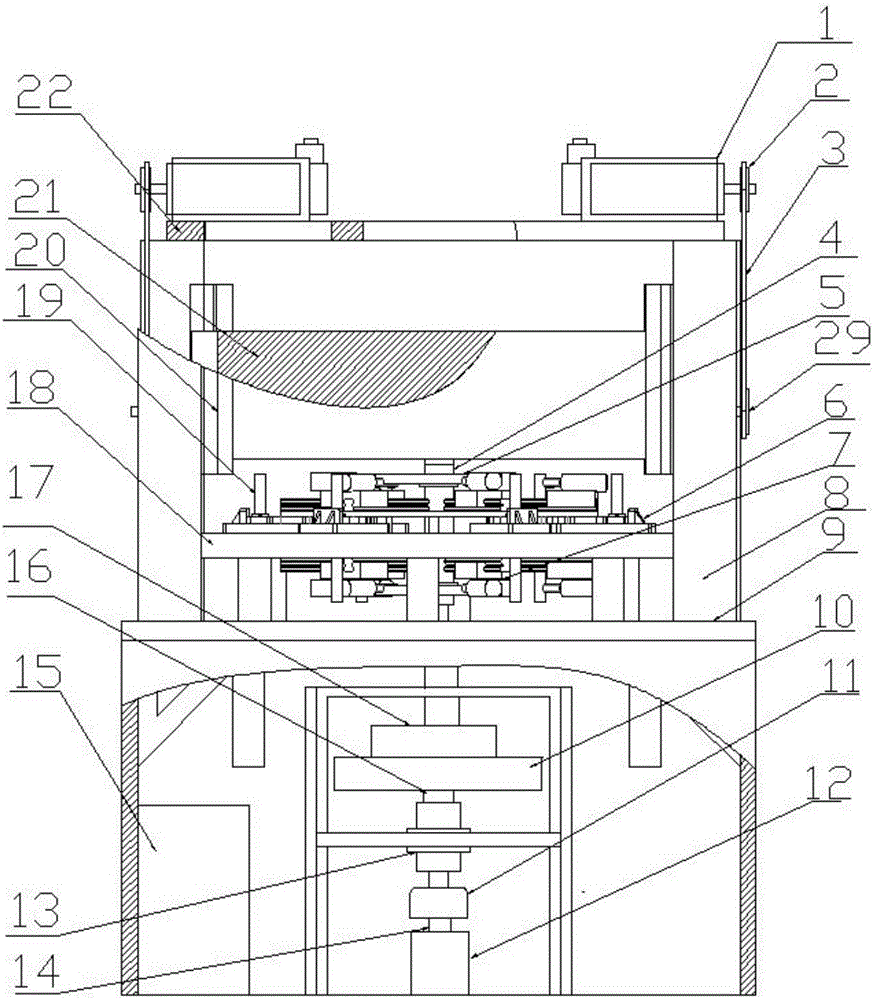

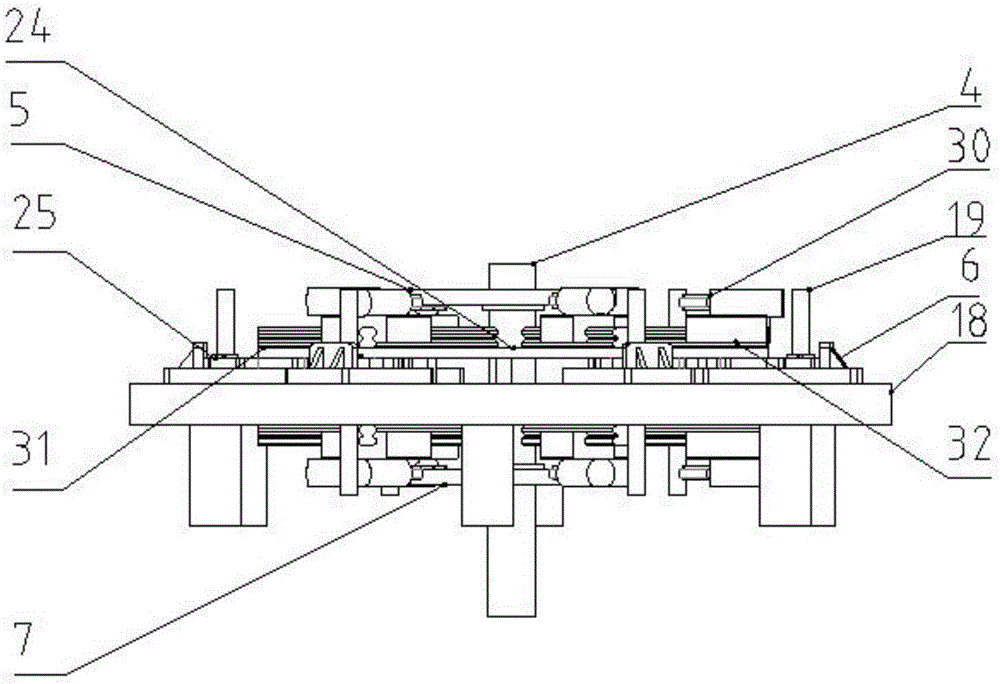

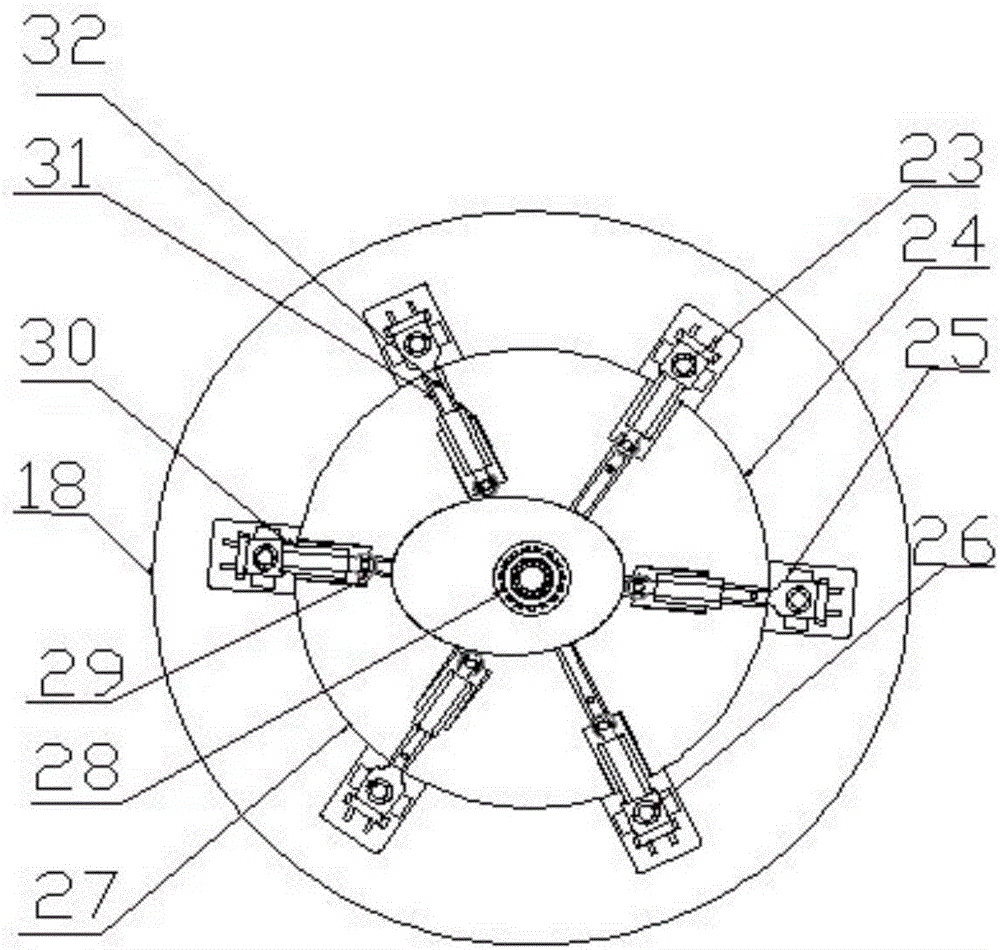

[0032] refer to figure 1 , radial cam loading and low-cycle fatigue cracking equipment for split connecting rod cracking, including a base 9, four uprights 8 are fixedly connected to the left and right sides of the base 9, and crossbeams 22 are fixedly connected to the upper sides of the four uprights 8, The left and right symmetry of the beam 22 is equipped with a servo motor 1, the output shaft of the servo motor 1 is equipped with a first lifting wheel 2, the first lifting wheel 2 is connected with the second lifting wheel 29 on the upper box body 21 by a steel wire belt 3, and the upper box The left and right ends of the body 21 cooperate with the four columns 8 through the guide groove 20, and the servo motor 1, the first lifting wheel 2, the steel wire belt 3 and the second lifting wheel 29 form a cam disc lifting mechanism;

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com