High-speed steel-based WC45 steel bonded hard alloy guide roller and manufacturing method thereof

A technology of steel-bonded hard alloy and guide rollers, applied in the field of steel rolling guide rollers, to achieve excellent physical and mechanical properties, prolong service life, improve production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

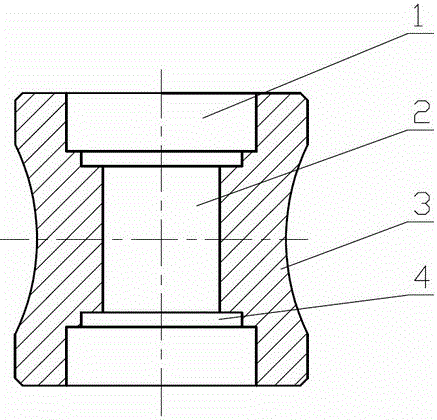

Image

Examples

Embodiment 1

[0031] The manufacturing process of the high-speed steel base WC45 steel-bonded cemented carbide guide roller of the present invention generally includes the following steps:

[0032] (1) Guide roller material:

[0033] The mass percentage of the chemical composition of the material is C0.62%, W3.0%, Cr4.15%, Mo3.0%, Si0.6%, Mn0.5%, WC45%, and the balance is Fe;

[0034] (2) Manufacture and processing of guide rollers:

[0035] 1) Forging the high-speed steel-based WC45 steel-bonded hard alloy manufactured by powder metallurgy;

[0036]2) Spheroidizing the forged high-speed steel-based WC45 steel-bonded hard alloy to make the hardness of the steel-bonded hard alloy <HRA74;

[0037] 3) The steel-bonded cemented carbide after spheroidizing annealing is processed according to the size required by the guide roller product, and a certain amount of grinding is reserved for the outer size of the guide roller and the inner hole of the bearing;

Embodiment 2

[0044] The manufacturing process of the high-speed steel base WC45 steel-bonded cemented carbide guide roller of the present invention generally includes the following steps:

[0045] (1) Guide roller material:

[0046] The mass percentage of the chemical composition of the material is C0.7%, W3.2%, Cr4.5%, Mo3.2%, Si0.8%, Mn0.6%, WC45%, and the balance is Fe;

[0047] (2) Manufacture and processing of guide rollers:

[0048] 1) Forging the high-speed steel-based WC45 steel-bonded hard alloy manufactured by powder metallurgy;

[0049] 2) Spheroidizing the forged high-speed steel-based WC45 steel-bonded hard alloy to make the hardness of the steel-bonded hard alloy <HRA74;

[0050] 3) The steel-bonded cemented carbide after spheroidizing annealing is processed according to the size required by the guide roller product, and a certain amount of grinding is reserved for the outer size of the guide roller and the inner hole of the bearing;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com