A modular traverse device

A traverse device and modular technology, applied in metal rolling, metal rolling stands, manufacturing tools, etc., can solve the problems of complex traverse control means, poor maintenance, heavy weight, etc., to ensure smooth operation and high weight. Light, accurate and firm installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

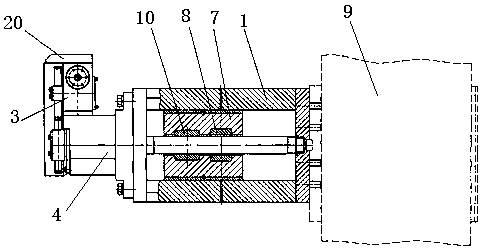

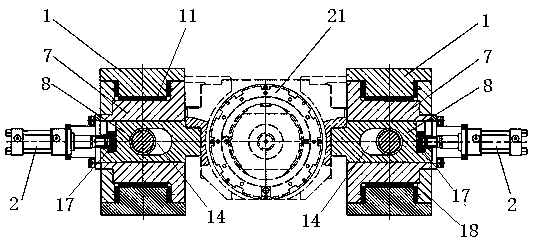

[0033] In order to overcome the problems of heavy weight, large volume, complicated means of traversing control and poor maintainability in the existing traversing mechanism of the intermediate roller, this embodiment provides a Figure 1 to Figure 7 The shown modular traverse device includes a frame 9 and two frame bodies 1 connected to the front end of the frame 9, the frame 9 is a symmetrical structure, and the two frame bodies 1 are symmetrically distributed on the center line of the frame 9 On both sides, slide blocks 7 are housed in the two frame bodies 1, and slideways 11 are provided on the upper and lower end surfaces of the slide block 1, and the slideways 11 on the upper and lower end surfaces of the slide block 7 are connected with the upper and lower end surfaces of the frame body 1 respectively. contact, and the slider 7 can slide back and forth in the frame body 1, the middle part of the slider 7 is provided with a through hole 12, and the through hole 12 is para...

Embodiment 2

[0039] On the basis of embodiment 1, this embodiment provides a kind of Figure 1 to Figure 7 In the modular traverse device shown, a position detector 16 is installed on the slider 7, and the position detector 16 is used to detect the position of the slider 7 to ensure the accuracy of the roller traverse position and realize automatic traverse control .

[0040] Further, in order to improve the maintainability of the position detector 16, the position detector 16 is installed externally.

Embodiment 3

[0042] On the basis of embodiment 2, this embodiment provides a kind of Figure 1 to Figure 7 Modular traversing units shown, such as Figure 7 As shown, one end of the locking pin 8 is provided with a T-shaped slot, and the bottom of the T-shaped slot is arc-shaped, and the other end is stepped. Blocked during operation to ensure unimpeded operation, the side surface of the locking pin 8 is also processed with a lubricating oil groove, which is convenient for adding lubricating oil to ensure the operation of the locking pin.

[0043] Further, such as Figure 6 As shown, one end of the locking pin 3 is connected to the piston rod of the locking cylinder 2 through a plug 17 . One end of the top 17 is provided with a step, and the step is stuck in the T-shaped groove of the locking pin 8 and matches with the T-shaped groove of the locking pin 8. The other end of the top 17 is provided with a threaded blind hole, which is connected with the locking cylinder 2 Piston rod connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com