Catalyst for preparing methylallyl alcohol through selective hydrogenation of methylacrolein and preparation method thereof

A technology for producing methallyl alcohol and methacrolein, which is applied in the preparation of hydroxyl compounds, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low conversion rate of raw materials and low product selectivity, and achieve high catalyst activity , good selectivity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

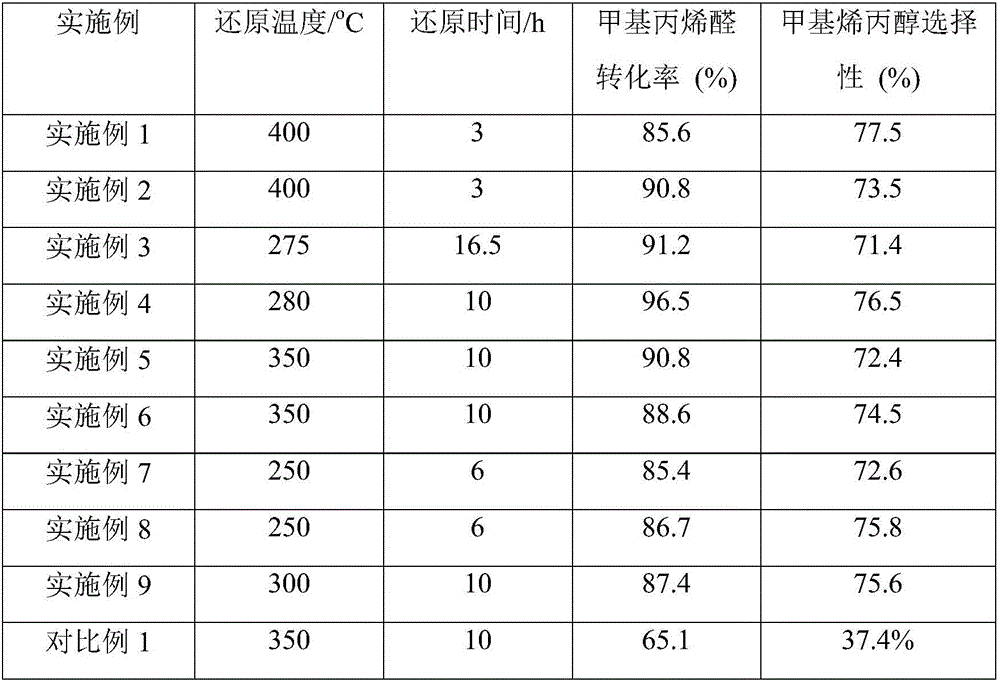

Examples

Embodiment 1

[0017] Weigh 20g TiO 2 Carrier, dissolved in a certain amount of copper sulfate solution containing polyethylene glycol, impregnated at room temperature for 12 hours, then stirred and dried at 80°C to obtain Cu / TiO 2 Precursor; the Cu / TiO 2 The precursor is dissolved in a certain amount of mixed solution of chloroauric acid and stannous chloride, soaked at room temperature for 12 hours, and then dried with stirring at 80°C. The obtained sample was dried at 80°C for 24h and calcined at 600°C for 4h to obtain a supported catalyst 33%Cu-0.1%Au-0.1%Sn / TiO 2 .

Embodiment 2

[0019] Weigh 20g ZrO 2 Carrier, dissolved in a certain amount of silver nitrate solution containing sodium lauryl sulfate, impregnated at room temperature for 12 hours, then stirred and dried at 80°C to obtain the precursor Ag / ZrO 2 Precursor; the Ag / ZrO 2 The precursor is dissolved in a certain amount of chloroiridic acid and lanthanum nitrate solution, soaked at room temperature for 12 hours, and then dried with stirring at 80°C. The obtained sample was dried at 150°C for 8h and calcined at 250°C for 12h to obtain a supported catalyst 0.5%Ag-5%Ir-%5La / ZrO 2 .

Embodiment 3

[0021] Weigh 20g ZnO carrier, dissolve it in a certain amount of silver nitrate solution containing polyvinylpyrrolidone, immerse it at room temperature for 12h, then stir and dry at 80°C to obtain the precursor Ag / ZnO precursor; dissolve the Ag / ZnO precursor in a certain The mixed solution of ruthenium chloride and manganese nitrate was impregnated at room temperature for 12 hours, and then dried with stirring at 80°C. The obtained sample was dried at 115° C. for 16 hours and calcined at 425° C. for 6 hours to obtain a supported catalyst 19% Ag-1% Ru-2% Mn / ZnO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com