Solar cell based on organic-inorganic hybrid perovskite oriented crystallization thin film

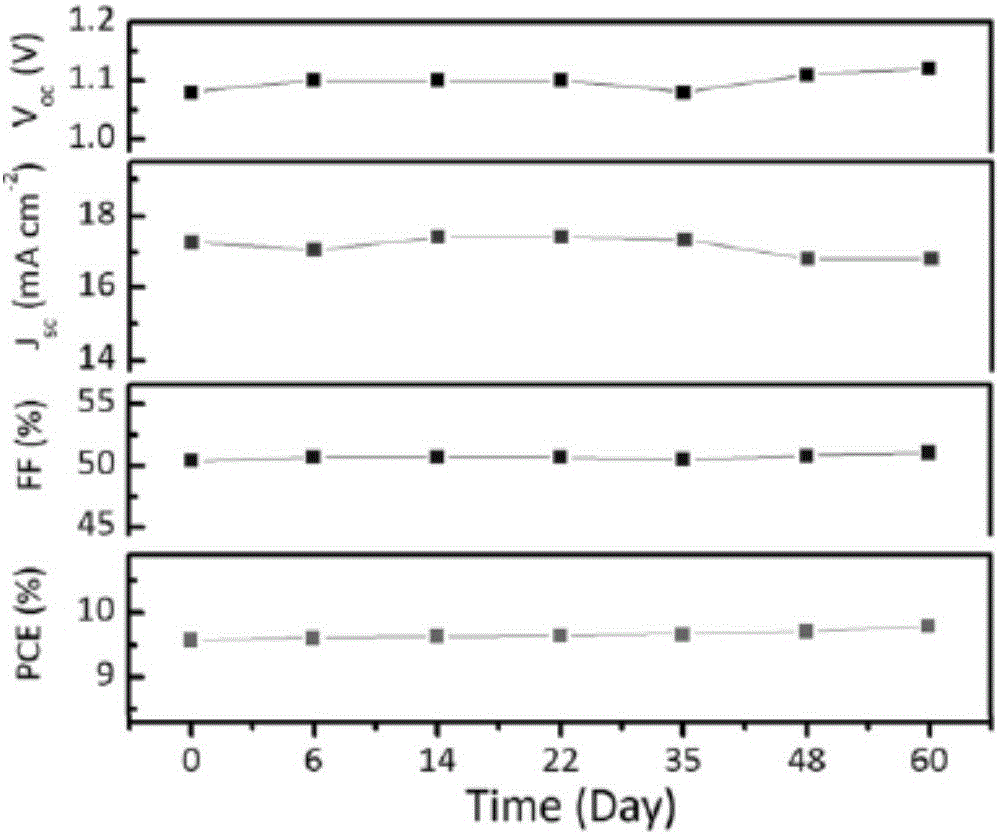

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as the barrier of charge transfer due to insulating properties, the inability to achieve photoelectric conversion efficiency, and the reduction of short-circuit current of solar cells, so as to achieve the effect of improving the carrier transport capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

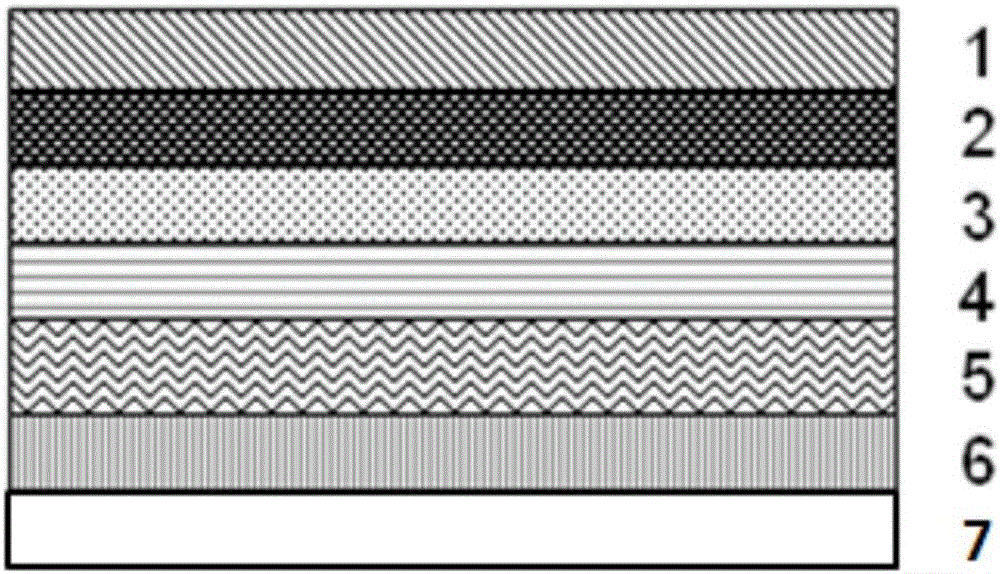

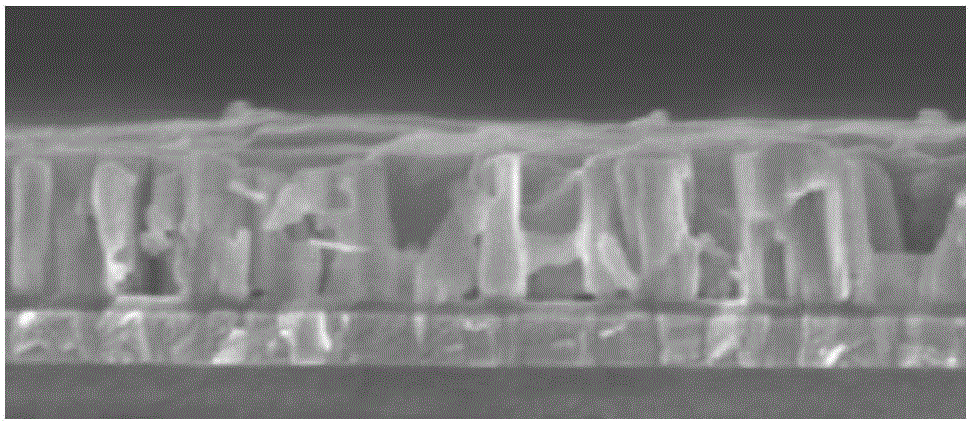

[0018] The glass substrate was ultrasonically washed with detergent, isopropanol, ethanol, and acetone for 5 minutes, rinsed with deionized water, and dried. Spin-coat a layer of metal aluminum with a thickness of 10nm on the glass substrate, after UV-ozone treatment, and then prepare a PEDOT:PSS hole transport layer with a thickness of about 40nm by spin coating, bake at 120°C for 15 minutes take out. Mix and dissolve methylamine iodide, n-butylamine hydriodide, lead iodide, and ammonium thiocyanate in N,N-dimethylformamide, lead iodide and N,N-dimethylformamide The proportioning ratio is 50 milligrams: 1 milliliter, ammonium iodide: n-butylamine hydroiodide: lead iodide: ammonium thiocyanate (molar ratio) is 2:2:3:0.005, stir overnight, obtain precursor body solution; using the method of solution spin coating, the precursor solution was spin-coated on the PEDOT:PSS layer to form a film, the rotation speed was 2000 rpm, the rotation time was 10 seconds, and annealed at 70°C ...

Embodiment 2

[0020] The quartz substrate was ultrasonically washed with detergent, isopropanol, ethanol, and acetone for 5 minutes, rinsed with deionized water and dried. Vacuum-deposit a layer of metallic silver with a thickness of 20nm on the quartz substrate, and after UV-ozone treatment, prepare a PEDOT:PSS hole transport layer with a thickness of about 40nm by spin coating, bake at 120°C for 15 minutes and take it out . Mix and dissolve methylamine iodide, n-butylamine hydriodide, lead iodide, and ammonium thiocyanate in N,N-dimethylformamide, lead iodide and N,N-dimethylformamide The proportioning ratio is 800 mg: 1 milliliter, ammonium iodide: n-butylamine hydroiodide: lead iodide: ammonium thiocyanate (molar ratio) is 2:2:3:1.5, stirs overnight, obtains precursor body solution; using the method of solution spin coating, the precursor solution was spin-coated on the PEDOT:PSS layer to form a film, the rotation speed was 8000 rpm, the rotation time was 60 seconds, and annealed at 15...

Embodiment 3

[0022] The quartz substrate was ultrasonically washed with detergent, isopropanol, ethanol, and acetone for 5 minutes, rinsed with deionized water and dried. A layer of metallic gold with a thickness of 25nm was vacuum evaporated on a quartz substrate. After UV-ozone treatment, a CuOx hole transport layer with a thickness of about 40nm was prepared by spin coating, and it was baked at 150°C for 15 minutes and then taken out. Mix and dissolve methylamine iodide, n-butylamine hydriodide, lead iodide, and ammonium thiocyanate in N,N-dimethylformamide, lead iodide and N,N-dimethylformamide The proportioning ratio is 500 mg: 1 milliliter, ammonium iodide: n-butylamine hydroiodide: lead iodide: ammonium thiocyanate (molar ratio) is 2:2:3:1, stirs overnight, obtains precursor The precursor solution is used for spin-coating, and the precursor solution is spin-coated on the CuOx layer to form a film. The spin speed is 5000 rpm, the spin time is 30 seconds, and annealed at 100°C for 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com