High-responsivity photodetectors based on moisture-resistant organic-inorganic hybrid perovskite materials

A technology of perovskite materials and photodetectors, which can be used in the manufacture of semiconductor devices, electrical solid state devices, semiconductor/solid state devices, etc., can solve problems such as high photoresponsivity, reduction of photodetector photocurrent, and insulation characteristic charge transmission barriers. , to achieve high responsivity and improve the effect of carrier transport ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

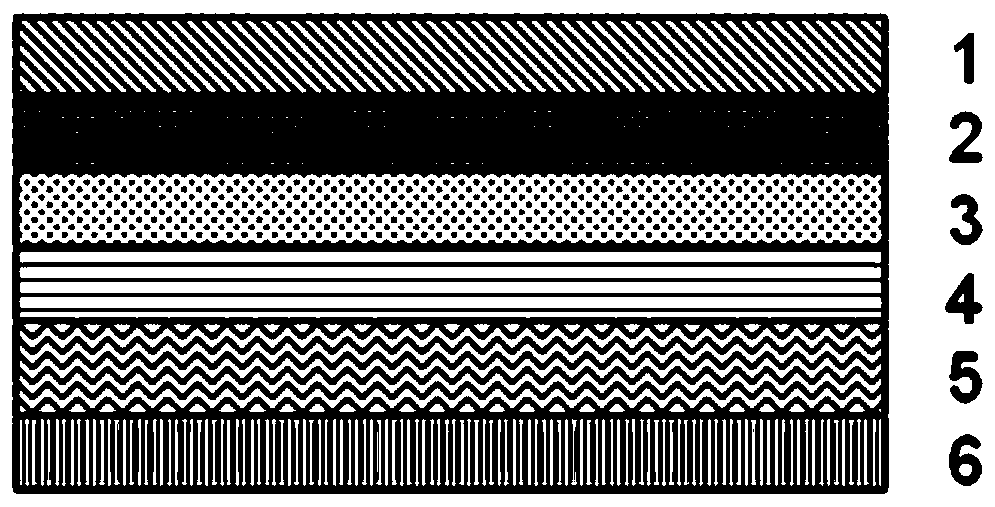

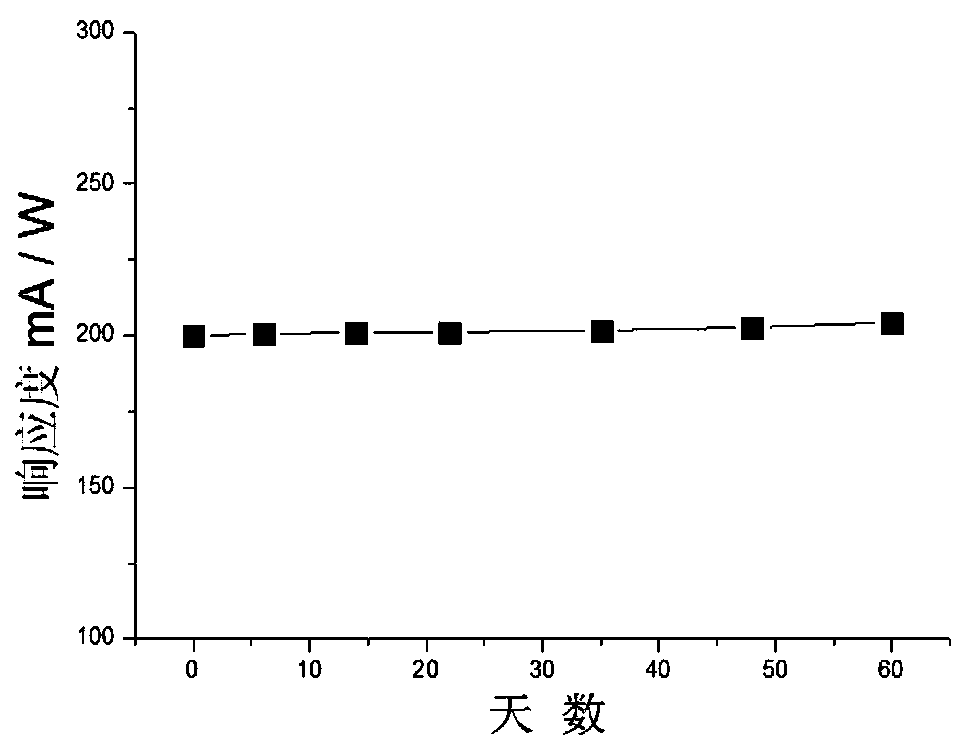

Embodiment 1

[0018] The glass substrate was ultrasonically washed with detergent, isopropanol, ethanol, and acetone for 5 minutes, then rinsed with deionized water and dried. A layer of metal aluminum with a thickness of 10nm was spin-coated on the glass substrate. After UV-ozone treatment, a PEDOT:PSS electron barrier layer with a thickness of about 40nm was prepared by the spin coating method, and baked at 120°C for 15 minutes and then taken out . Mix and dissolve methyl iodide, n-butylamine hydroiodide, lead iodide, and ammonium thiocyanate in N,N-dimethylformamide, lead iodide and N,N-dimethylformamide The mixing ratio is 50 mg: 1 ml, methyl amine iodide: n-butylamine hydroiodide: lead iodide: ammonium thiocyanate (molar ratio) is 2:2:3:0.005, stirred overnight to obtain the precursor Body solution; using the solution spin coating method, take the precursor solution and spin-coat on the PEDOT:PSS layer to form a film at a rotation speed of 2000 revolutions per minute, a rotation time o...

Embodiment 2

[0020] The quartz substrate was ultrasonically washed with detergent, isopropanol, ethanol, and acetone for 5 minutes, then rinsed with deionized water and dried. A layer of 20nm thick metallic silver was vacuum-evaporated on the quartz substrate. After UV-ozone treatment, a PEDOT:PSS electron barrier layer with a thickness of about 40nm was prepared by a spin coating method, and it was baked at 120°C for 15 minutes and then taken out. Mix and dissolve methyl iodide, n-butylamine hydroiodide, lead iodide, and ammonium thiocyanate in N,N-dimethylformamide, lead iodide and N,N-dimethylformamide The ratio of the mixture is 800 mg: 1 ml, methyl amine iodide: n-butylamine hydroiodide: lead iodide: ammonium thiocyanate (molar ratio) is 2:2:3:1.5, stirred overnight to obtain the precursor Body solution; using the solution spin coating method, take the precursor solution and spin-coated on the PEDOT:PSS layer to form a film at a rotation speed of 8000 rpm, a rotation time of 60 seconds...

Embodiment 3

[0022] The quartz substrate was ultrasonically washed with detergent, isopropanol, ethanol, and acetone for 5 minutes, then rinsed with deionized water and dried. A layer of 25nm thick metal gold was vacuum-evaporated on the quartz substrate, and after UV-ozone treatment, a CuOx electron blocking layer with a thickness of about 40nm was prepared by a spin coating method, and it was baked at 150°C for 15 minutes and then taken out. Mix and dissolve methyl iodide, n-butylamine hydroiodide, lead iodide, and ammonium thiocyanate in N,N-dimethylformamide, lead iodide and N,N-dimethylformamide The ratio is 500 mg: 1 ml, methyl amine iodide: n-butylamine hydroiodide: lead iodide: ammonium thiocyanate (molar ratio) is 2:2:3:1, stirred overnight to obtain the precursor Body solution; using the solution spin coating method, take the precursor solution to spin coating on the CuOx layer to form a film at a rotation speed of 5000 rpm, a rotation time of 30 seconds, and an annealing at 100°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com