LNG (Liquefied Natural Gas) storage tank rollover suppression device

A technology for suppressing devices and storage tanks, applied in the field of LNG storage, can solve problems such as power consumption, potential safety hazards, large BOG, etc., and achieve the effects of no noise interference, suppression of LNG tumbling, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

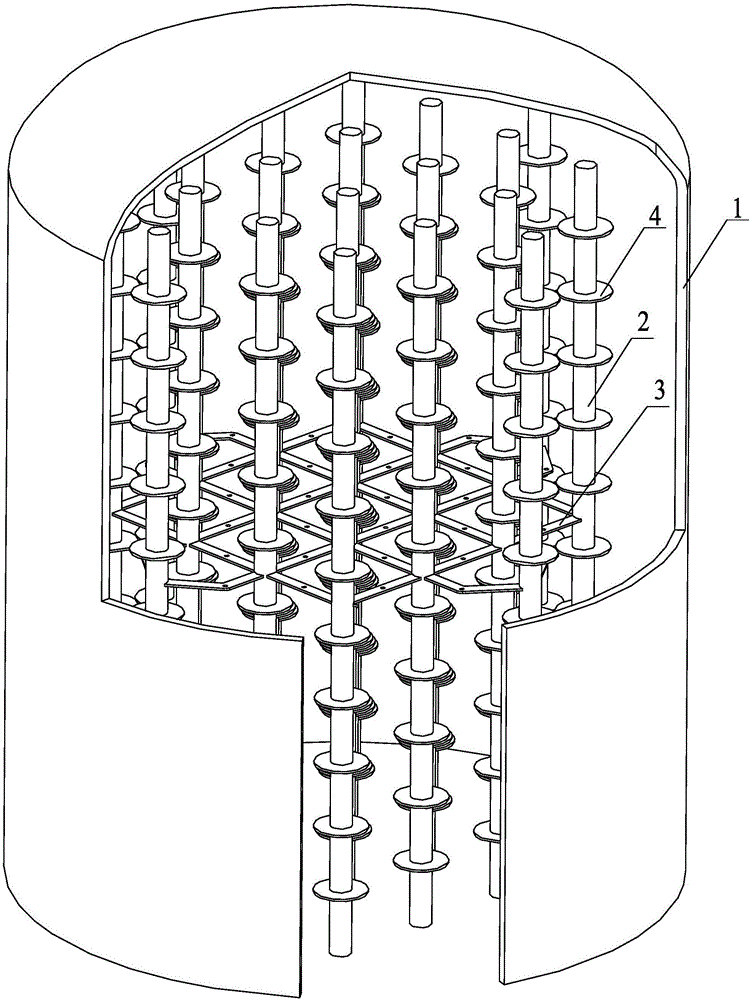

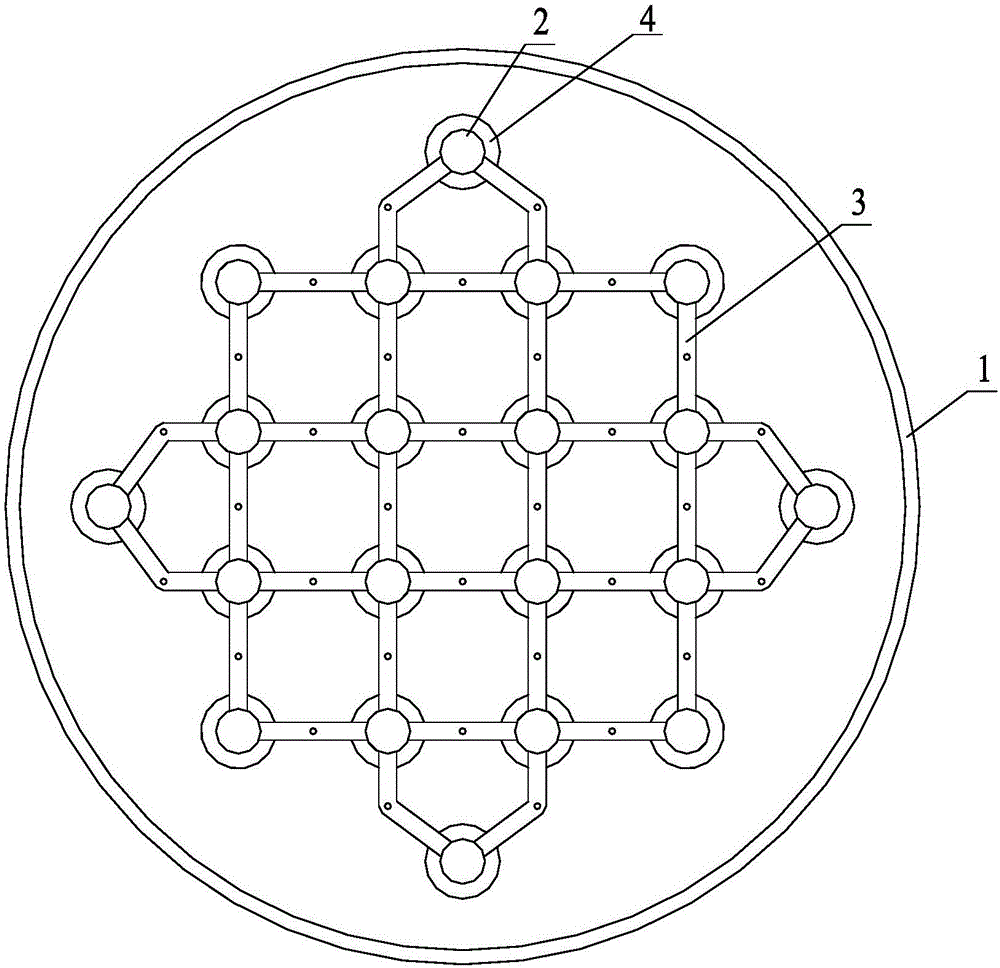

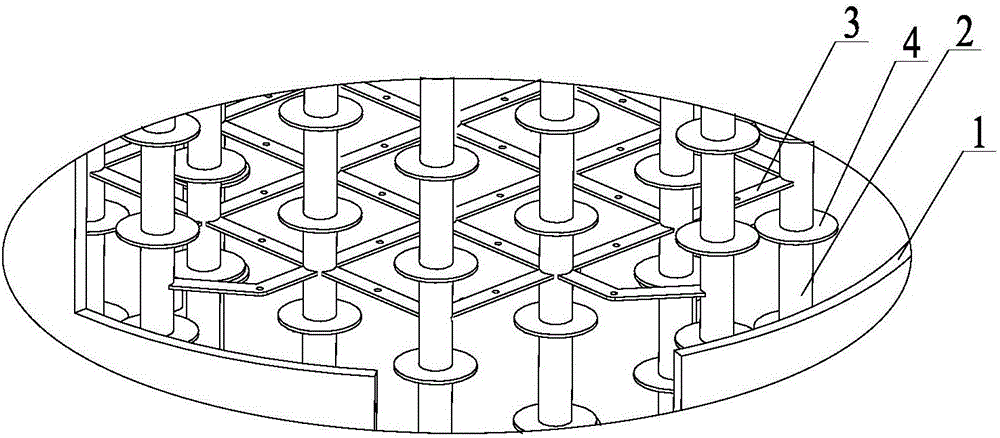

[0025] like figure 1 As shown, the present invention relates to an LNG storage tank rollover suppression device, which mainly includes: an LNG storage tank 1, a heat pipe 2 and a connector 3, the heat pipe 2 is upright in the LNG storage tank 1, and several heat pipes 2 are in the LNG storage tank 1 Evenly arranged, adjacent heat pipes are connected to each other through connectors 3 .

[0026] like figure 2 The heat pipe 2 is a cylindrical body sealed at both ends, made of metal, filled with liquid nitrogen as a working medium after being evacuated into a vacuum, and annular fins 4 are evenly arranged on the pipe wall along the axial direction.

[0027] The heat pipe 2 transfers heat by the phase change of the internal working fluid and steam flow, and the latent heat transfer efficiency of the phase change is much higher than that of convective heat transfer and general heat conduction. The upper part of the heat pipe 2 is the condensing section, and the lower part is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com