Method for preparing SnO2 micro-nanofiber

A technology of micro-nano fiber and polyvinylpyrrolidone, which is applied in the field of preparation of SnO2 micro-nano fiber, achieves good gas-sensing performance, controllable reaction parameters, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

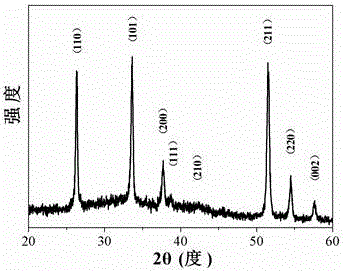

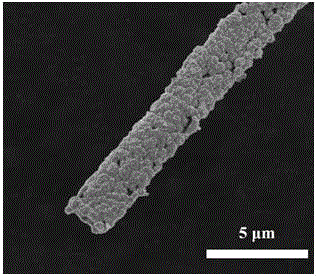

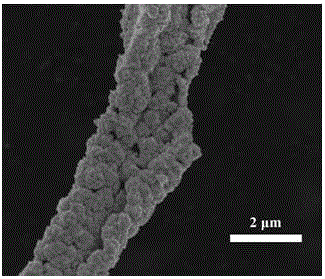

Image

Examples

Embodiment 1

[0036] 1.1 Mix 4.321 g of tin tetrachloride pentahydrate (SnCl 4 ∙5H 2 O) and 2.067 g of hexamethylenetetramine (HMT) were added to a mixed solvent of 18.0 mL of deionized water and 9.0 mL of glycerol, and stirred to obtain a transparent solution, which was transferred to a reaction kettle and placed in a After reacting at 120 °C for 3 h, place it in a constant temperature water bath at 90 °C and stir for 4 h to obtain a precursor solution;

[0037] 1.2 Dissolve 1.998 g of PVP and 1.552 g of stearic acid (SA) in a mixed solvent of 6.0 mL of deionized water and 3.0 mL of DMF, slowly add it to the precursor solution obtained in 1.1, and stir for 6 h to obtain the precursor The body spinning solution was used to obtain precursor fibers by electrospinning. The spinning parameters were as follows: positive voltage 15 KV, negative voltage 0.5 KV, receiving distance 14 cm, and syringe advancing speed 0.001 mm / s.

[0038] 1.3 Place the precursor fiber in a muffle furnace, raise the ...

Embodiment 2

[0041] 2.1 Add 3.315 g of SnCl 4 ∙5H 2 O and 1.392 g of HMT were added to a mixed solvent of 20.0 mL of deionized water and 6.0 mL of glycerol, and stirred to obtain a transparent solution. The solution was transferred to a reaction kettle, and after reacting at 110 °C for 6 h, set Stir in a constant temperature water bath at 80°C for 8 h to obtain a precursor solution;

[0042] 2.2 After dissolving 1.376 g of PVP and 0.784 g of SA in a mixed solvent of 5.0 mL of deionized water and 3.0 mL of DMF, they were slowly added to the precursor solution obtained in 2.1, and stirred for 2 h to obtain a precursor spinning solution. The precursor fibers were obtained by electrospinning. The spinning parameters were as follows: positive voltage 10 KV, negative voltage 0.5 KV, receiving distance 15 cm, and syringe advancing speed 0.002 mm / s.

[0043] 2.3 Place the precursor fiber in a muffle furnace, raise the temperature from room temperature to 300 °C at a rate of 2 °C / min, keep it for...

Embodiment 3

[0045] 3.1 Add 4.887 g of SnCl 4 ∙5H 2 O and 2.832 g of HMT were added to a mixed solvent of 16.0 mL of deionized water and 9.6 mL of glycerol, and stirred to obtain a transparent solution. The solution was transferred to a reaction kettle and reacted at 120 °C for 1 h. Stir in a constant temperature water bath at 90°C for 1 h to obtain a precursor solution;

[0046] 3.2 After dissolving 1.987 g of PVP and 1.954 g of SA in a mixed solvent of 5.0 mL of deionized water and 1.5 mL of DMF, they were slowly added to the precursor solution obtained in 3.1, and stirred for 7 h to obtain a precursor spinning solution. Precursor fibers were obtained by electrospinning. The spinning parameters were as follows: positive voltage 16 KV, negative voltage 0.5 KV, receiving distance 10 cm, and syringe advancing speed 0.001 mm / s.

[0047] 3.3 Place the precursor fiber in a muffle furnace, raise the temperature from room temperature to 300 °C at a rate of 1 °C / min, keep it warm for 4 h, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com