Heat treatment method for improving toughness of die-casting magnesium alloy

A heat treatment method and toughness technology are applied in the field of heat treatment to improve the strength and toughness of die-casting magnesium alloys, which can solve the problems of high cost, limited strength and toughness, and limited application scope, and achieve the effect of preventing grain coarsening and improving strength and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

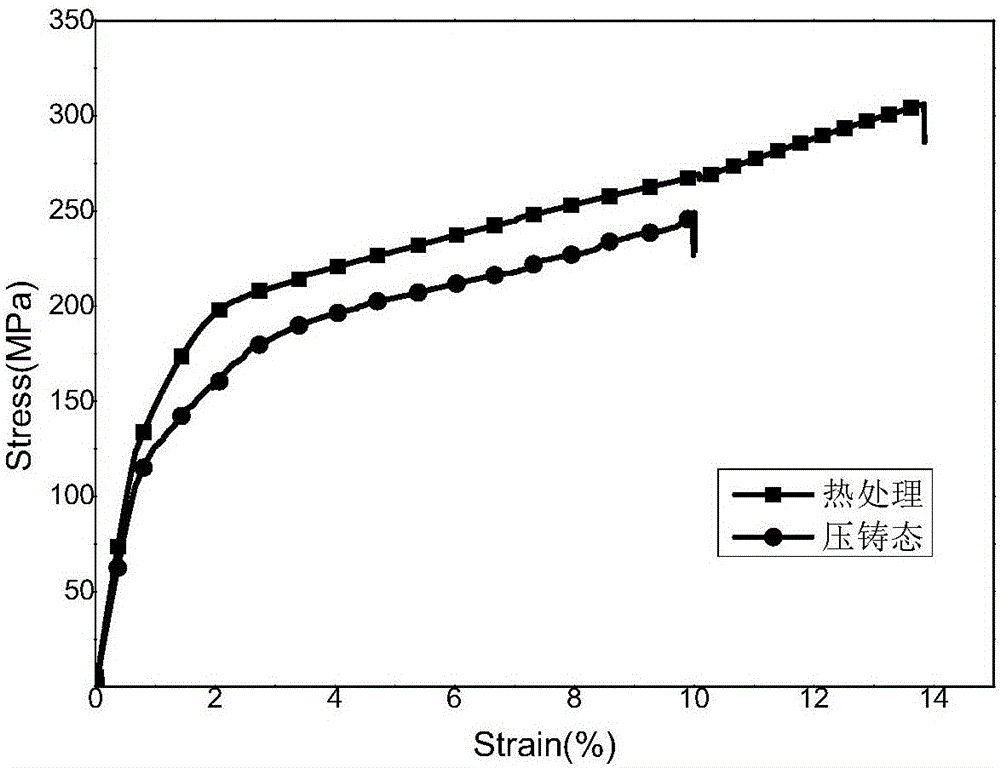

[0035] Put the Mg-7Al-1Ca-0.5Sn alloy prepared by vacuum die-casting into a heat treatment furnace for a heat treatment. The temperature of the first heat treatment is 380°C, and the furnace is installed at room temperature. The heating rate is 3°C / min, and the time of the first heat treatment is 13h; complete After one heat treatment, the samples were taken out and cooled in air. Put the sample into a heat treatment furnace for secondary heat treatment. The temperature of the secondary heat treatment is 190°C, the furnace is installed at room temperature, the heating rate is 3°C / min, and the time of the secondary heat treatment is 14h. After the secondary heat treatment, the sample is taken out and air-cooled. The resulting alloy has a yield strength of 155.4MPa, a tensile strength of 293.9MPa, and an elongation of 12.84%.

Embodiment 2

[0037] Put the Mg-7Al-1Ca-0.5Sn alloy prepared by vacuum die-casting into a heat treatment furnace for a heat treatment. The temperature of the first heat treatment is 400 ° C, the furnace is installed at room temperature, the heating rate is 5 ° C / min, and the time of the first heat treatment is 16 h; After one heat treatment, the samples were taken out and cooled in air. Put the sample into the heat treatment furnace for the second heat treatment, the temperature of the second heat treatment is 210°C, the furnace is installed at room temperature, the heating rate is 5°C / min, and the time of the second heat treatment is 18 h; after the second heat treatment, the sample is taken out and air-cooled . The resulting alloy has a yield strength of 148.5MPa, a tensile strength of 288.9MPa, and an elongation of 12.5%.

Embodiment 3

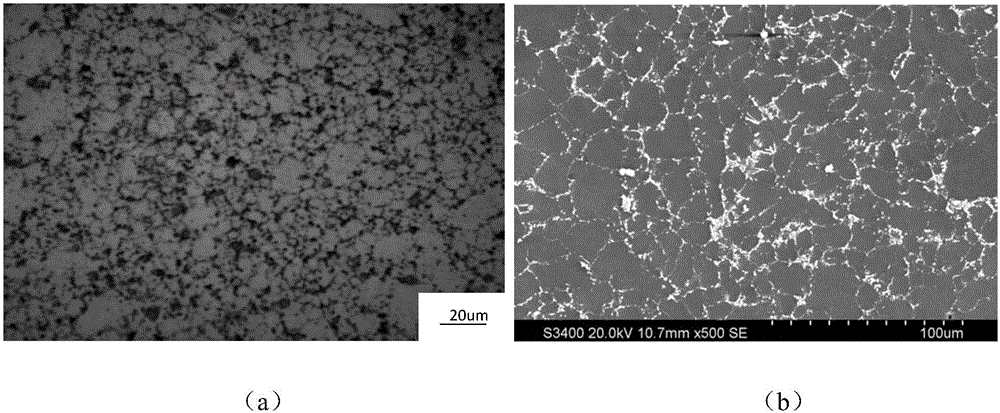

[0039] Put the Mg-7Al-1Ca-0.5Sn alloy prepared by vacuum die-casting into a heat treatment furnace for a heat treatment. The temperature of the first heat treatment is 390°C, the furnace is installed at room temperature, the heating rate is 4°C / min, and the time of the first heat treatment is 15h; complete After the first heat treatment, take out the sample and air-cool; put the sample into a heat treatment furnace for the second heat treatment, the temperature of the second heat treatment is 200°C, install the furnace at room temperature, the heating rate is 4°C / min, and the time of the second heat treatment is 15h; After the secondary heat treatment, the samples were taken out and cooled in air. The resulting alloy has a yield strength of 178.2MPa, a tensile strength of 306.8MPa, and an elongation of 13.8%. The tensile mechanical properties of vacuum die-casting Mg-7Al-1Ca-0.5Sn alloy before and after heat treatment are as follows: figure 1 shown. Microstructure of Mg-7Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com