Method for removing foam during simultaneous saccharification and fermentation of lignocellulose with high solid content

A lignocellulosic, high solid content technology, applied in fermentation, biofuel, etc., can solve problems such as ineffectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

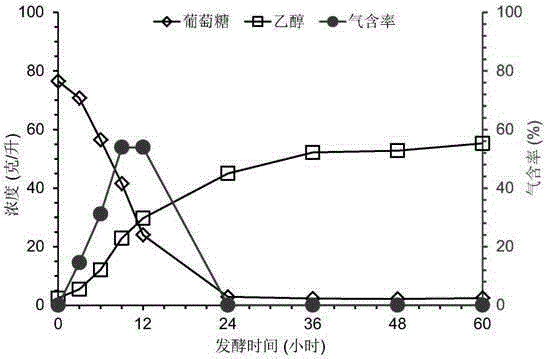

Embodiment 1

[0019] Add 1200g of dry straw after dedusting and crushing and 600g of dilute sulfuric acid solution with 5% mass fraction into a pretreatment reactor equipped with a ribbon-type stirring paddle to carry out high-temperature pretreatment reaction. The reaction conditions are 175°C, 2.5% dilute sulfuric acid consumption, The stirring speed is 50 rpm, and the temperature rises to 175°C and reacts for 5 minutes. Take out the pretreated material from the reactor, take 1500g and add it to a 5L bioreactor with a ribbon stirring paddle, and turn on the stirring speed of 50 rev / min, after adjusting the pH value to 5.5 with a calcium hydroxide solution of 20% mass concentration, insert 90 g of solid detoxified seeds cultivated in stalks with an inoculum size of 10% by mass ratio, stop stirring after mixing evenly, and start Solid-state biodegradation process, add 750ml deionized water after 48 hours of detoxification, saccharify with 85g of Youtel cellulase (15FPU / g) at 50°C and 150rpm ...

Embodiment 2

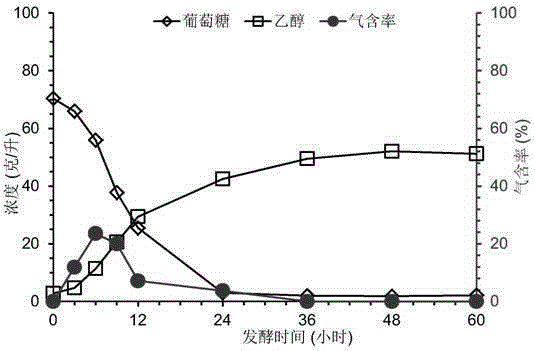

[0021] Add 1200g of dry straw after dedusting and crushing and 600g of dilute sulfuric acid solution with 5% mass fraction into a pretreatment reactor equipped with a ribbon-type stirring paddle to carry out high-temperature pretreatment reaction. The reaction conditions are 175°C, 2.5% dilute sulfuric acid consumption, The stirring speed is 50 rpm, and the temperature rises to 175°C and reacts for 5 minutes. Take out the pretreated material from the reactor, take 1500g and add it to a 5L bioreactor with a ribbon stirring paddle, and turn on the stirring speed of 50 rev / min, after adjusting the pH value to 5.5 with a calcium hydroxide solution of 20% mass concentration, insert 90 g of solid detoxified seeds cultivated in stalks with an inoculum size of 10% by mass ratio, stop stirring after mixing, and start Solid-state biodegradation process, add 750ml deionized water after 48 hours of detoxification, saccharify with 85g of Youtel cellulase (15FPU / g) at 50°C and 150rpm stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com