Roof structure, manufacturing method thereof, and vehicle

A roof and protrusion technology, applied in the field of vehicles, can solve the problems of roaring sound in the carriage, easy loosening of the roof, and reduced strength of the roof, so as to improve production efficiency, save manpower and material costs, and avoid duplication of labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

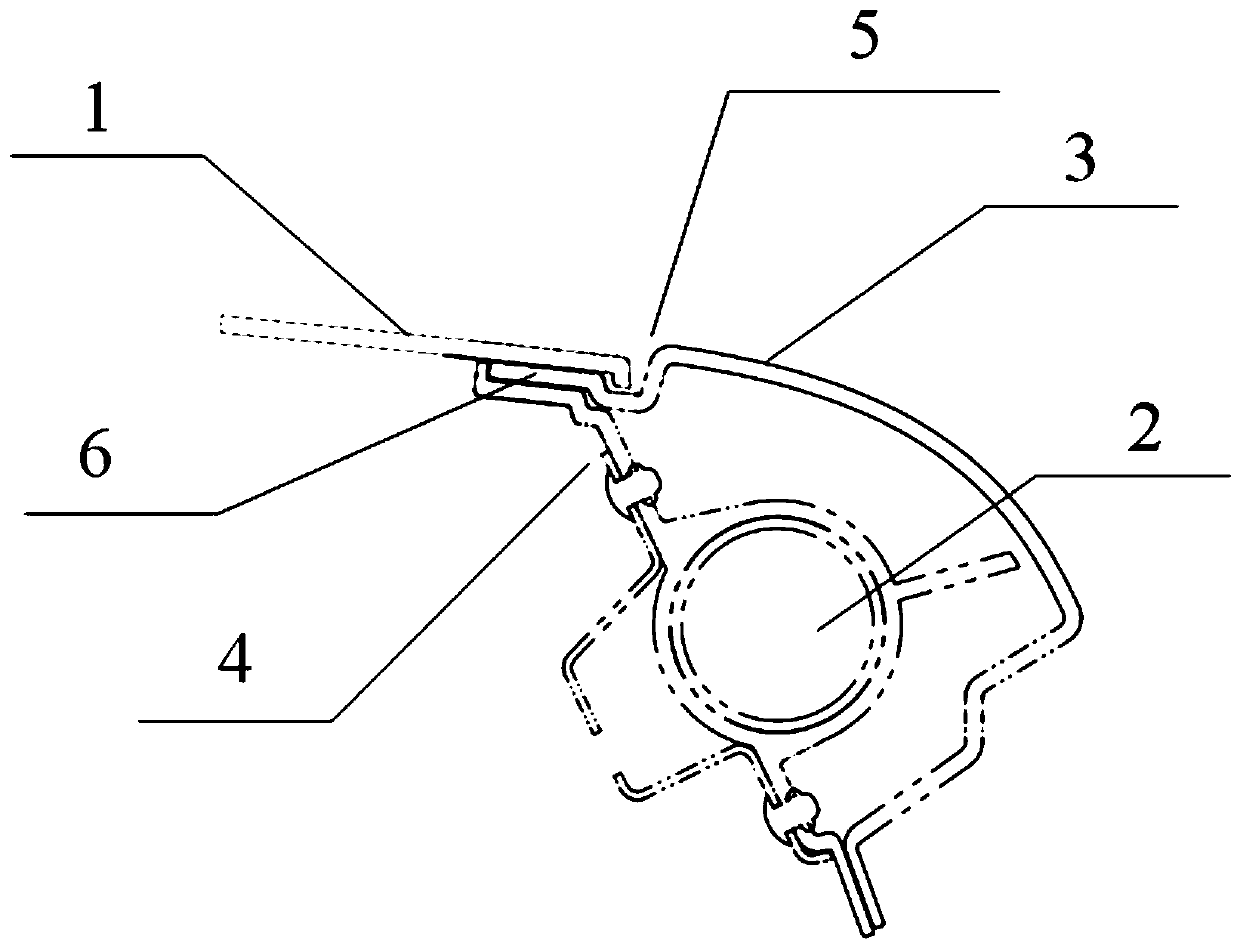

[0025] Such as figure 1 As shown, Embodiment 1 of the present disclosure provides a vehicle roof structure, including a roof 1, a cowl cover 3 and an upper vehicle body assembly 2, the upper side of the cowl cover 3 is provided with a groove 5, The groove 5 divides the upper enclosure cover 3 into two parts, one side of the groove 5 is the upper enclosure cover main body, and the other side of the groove is the upper enclosure cover protrusion 6;

[0026] The front edge of the top cover 1 is bent downwards and extends into the groove 5, and the bottom surface of the top cover close to the front edge is in close contact with the upper surface of the protruding portion 6 of the upper wall cover;

[0027] The upper vehicle body assembly 2 includes a first protruding portion 4 extending upwards, and the outer surface of the first protruding portion is in close contact with the lower surface and end surface of the protruding portion of the upper wall cover and the bottom surface of...

Embodiment 2

[0037] Embodiment 2 of the present disclosure provides a manufacturing method for the roof structure described in Embodiment 1 of the present disclosure. Firstly, the upper vehicle body assembly is installed, and then the upper wall cover and the first protruding part are glued together. Fix the bonding, and finally fix the top cover on the upper side of the upper wall cover by applying glue.

Embodiment 3

[0039] Embodiment 3 of the present disclosure provides a vehicle including the roof structure described in Embodiment 1 of the present disclosure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com