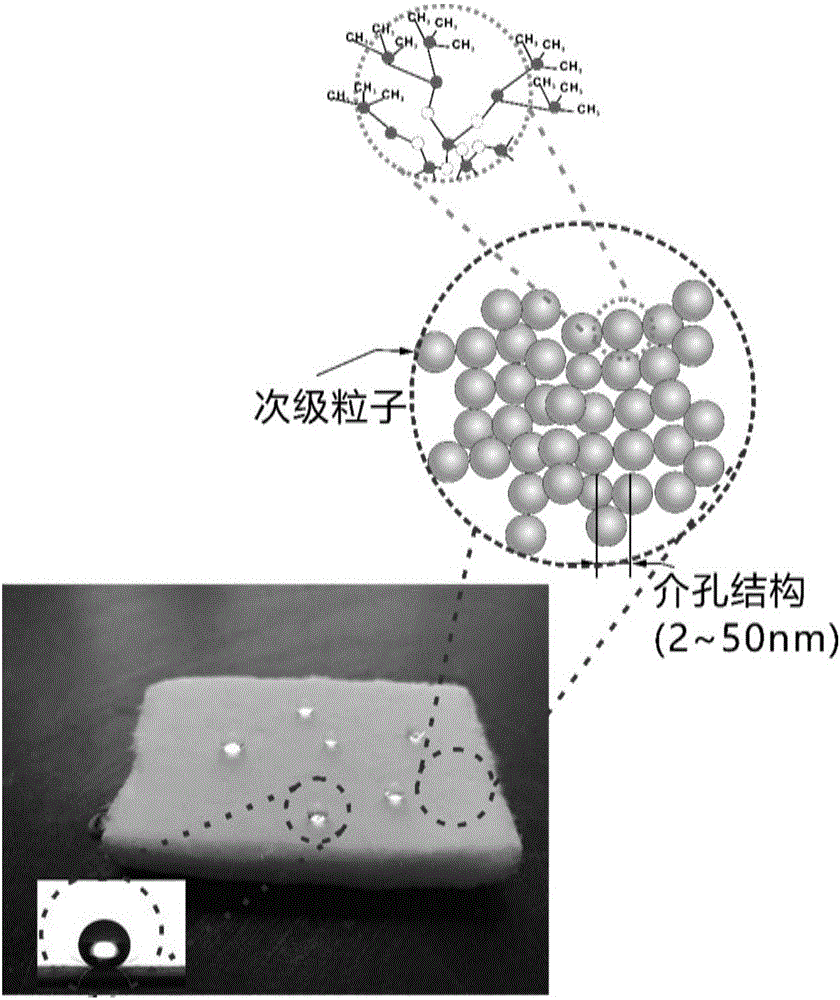

Ultrasonic-assisted method for preparing hydrophobic silicon dioxide aerogel composite materials

A technology of hydrophobic silica and composite materials, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as high cost, unfavorable production and promotion, and achieve low cost, short preparation period, and controllable degree. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for ultrasonically assisted preparation of hydrophobic silica airgel composites proposed by the present invention comprises the following steps:

[0029] S1, dilute the water glass with water, mix with acid solution and hydrolyze to obtain solution A;

[0030] S2, adding a basic catalyst to solution A, adjusting the pH value of the solution to 5, and obtaining solution B;

[0031] S3, adding the organic solvent into the solution B, stirring evenly and pouring it into a mold carrying a glass fiber mat to obtain a wet gel fiber mat;

[0032] S4, aging the wet gel fiber felt pad;

[0033] S5. Put the aged wet gel fiber mat in a container, add a silane modifier and an acid solution, then place the container in an ultrasonic generator for ultrasonic modification, and obtain the hydrophobic carbon dioxide after drying in an oven. Silicone airgel composite material, its relevant parameters are as follows: thermal conductivity is 0.0234W / (m K), hydrophobic angle is 1...

Embodiment 2

[0035] A method for ultrasonically assisted preparation of hydrophobic silica airgel composites proposed by the present invention comprises the following steps:

[0036] S1, dilute the water glass with water, mix with acid solution and hydrolyze to obtain solution A;

[0037] S2, adding a basic catalyst to solution A, adjusting the pH value of the solution to 3, and obtaining solution B;

[0038] S3, adding the organic solvent into the solution B, stirring evenly and pouring it into a mold carrying a glass fiber mat to obtain a wet gel fiber mat;

[0039] S4, aging the wet gel fiber felt pad;

[0040] S5. Put the aged wet gel fiber mat in a container, add a silane modifier and an acid solution, then place the container in an ultrasonic generator for ultrasonic modification, and obtain the hydrophobic carbon dioxide after drying in an oven. Silicone airgel composite material, its relevant parameters are as follows: thermal conductivity is 0.0237W / (m K), hydrophobic angle is 1...

Embodiment 3

[0042] A method for ultrasonically assisted preparation of hydrophobic silica airgel composites proposed by the present invention comprises the following steps:

[0043] S1. Dilute the water glass with water, and mix it with the acid solution for hydrolysis reaction to obtain solution A; wherein, the volume ratio of water glass and water is 1:1; during the mixed hydrolysis reaction, the temperature is 60°C, and the time is 10 minutes; The acid is hydrochloric acid, and the concentration of the acid solution is 12mol / L;

[0044] S2, adding a basic catalyst to the solution A, adjusting the pH value of the solution to 3 to obtain a solution B; wherein the basic catalyst is a sodium carbonate solution, and the concentration of the basic catalyst is 0.01mol / L;

[0045]S3, adding the organic solvent into the solution B, stirring evenly and then pouring it into a mold loaded with glass fiber felt to obtain a wet gel fiber felt pad; wherein, the organic solvent is ethanol, and the vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com